Return to Supplier

The Return to Supplier feature facilitates the return of goods or services to suppliers as a result of defects or other reasons for dissatisfaction.

It simplifies the process of returns and provides an efficient method of controlling items leaving site for returns or repairs. This ensures visibility and tracking of the item until the process is concluded.

Exploring

The programs related to this feature are accessed from the Program List of the SYSPRO menu:

- Program List > Return to Supplier

Suppliers provide a mechanism for you to raise purchase orders within SYSPRO, as well as being used as a selection criterion to generate reports.

You can configure group suppliers to facilitate group and intercompany group payments (i.e. processing a single large remittance to a primary supplier instead of multiple payments to many individual suppliers).

Static information configured against a supplier is used to determine applicable tax, discounts, etc., when processing purchasing transactions.

Documents received from a supplier (e.g. invoices, credit notes, debit notes, etc.) are stored against the supplier and let you keep track of the company's liabilities.

You maintain supplier details using the Suppliers program and you create group suppliers using the AP Group Suppliers program (Program List > Accounts Payable > Setup).

A stock code is a number that uniquely identifies an inventory item that is bought or manufactured and which is typically stored in one or more warehouses.

All activity relating to the forecasting, purchasing, manufacturing, stocking and selling of a stocked item is tracked by means of the stock code.

A stock code can be linked to one or more lot numbers if the item is defined as lot traceable. If there is a warranty, the stock code can be defined as serialized and linked to one or more serial numbers.

Within SYSPRO, a non-stocked code is allocated to an inventory item that you don't stock in any of your warehouses.

Non-stocked codes are created using the Non-stocked Codes program. They are used in the Quotations module to uniquely identify items that can be used within the Quotations and Estimates programs.

Non-stocked codes created using the Non-stocked Codes program can be converted into stocked codes if the New stock code in non-stocked table setup option is enabled (Setup Options > Preferences > Distribution > Inventory).

A Goods received note refers to the mechanism whereby you capture accrual values for items received into stock that have not yet been invoiced.

Return Merchandise Authorization refers to the document that is used to track items that are returned by a customer.

It includes flexible methods for dealing with the return or exchange of merchandise. You issue an RMA once the customer notifies you of the intent to return a product. At this point you can cross-ship a replacement item to the customer.

An RMA is typically required under the following circumstances:

- The incorrect product was sent to the customer and the customer needs to be credited.

- The correct product was sent to the customer, but the product is faulty and needs to be replaced or repaired.

- The customer is unhappy with the product and requires a credit.

- The product is partially faulty and the customer cannot ship it back without jeopardizing day-to-day operations. You need to ship a replacement part and the customer will return the faulty product within a specified time frame, or be billed for the replacement product.

Starting

The Return to Supplier module is a separate licensed module that replaces and supersedes the Return to Vendor add-on module.

If you have previously used the Return to Vendor functionality, you must run the RTS Conversion Check program before using the Return to Supplier functionality.

If you have used the RTV module and are upgrading to SYSPRO 8 2019 R2, you must request an updated SYSPRO 8 license that includes the Return to Supplier module to ensure a seamless transition from the Return to Vendor module to the Return to Supplier module.

To use this feature, the following module(s) must be installed according to the terms of your software license agreement:

- Return to Supplier

- Purchase Orders

- Inventory Control

- Return Merchandise (if you want to use the RMA functionality to process returns from customers)

You can secure this feature by implementing a range of controls against the affected programs. Although not all these controls are applicable to each feature, they include the following:

- You restrict operator access to activities within a program using the Operator Maintenance program.

- You can restrict operator access to the fields within a program (configured using the Operator Maintenance program).

- You can restrict operator access to functions within a program using passwords (configured using the Password Definition program). When defined, the password must be entered before you can access the function.

- You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program). Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

- You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

- You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

The Setup Options program lets you configure how SYSPRO behaves across all modules. These settings can affect processing within this program.

Setup Options > Configuration > Distribution > Purchase Orders

- GRN suspense system required

Solving

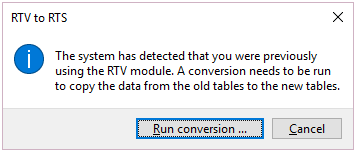

If you previously used the legacy Returned to Vendor system and have not yet performed the conversion, then these messages are displayed in succession when you attempt to access any program within the Return to Supplier module.

-

Upon receiving the first message, select Run Conversion to begin the conversion process.

The legacy RTV tables are renamed and converted to use the new Return to Supplier functionality.

-

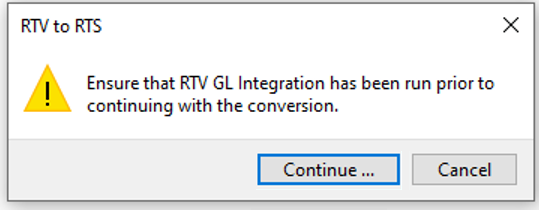

When the second message is displayed, select Continue to copy the journals from the legacy RTV tables to the latest RTS tables.

You only need to run the conversion if you have used the Return to Vendor system and you are upgrading to SYSPRO 8 2019 R2

You can run the conversion right after upgrading to SYSPRO 8 2019 R2.

If you don't run the conversion and you attempt accessing any program within the Return to Supplier module, you will be prompted to do the conversion first.

If you are on any earlier versions (released before SYSPRO 8 2019 R2), you can continue to use the Return to Vendor (RTV) add-on module.

- Upgrade to SYSPRO 8 2019 R2.

- Access SYSPRO 8.

-

Run the RTS Conversion Check program by selecting the option and entering RTSUCC in the Program to run field. Then follow the prompts.

Using

The programs related to this feature are accessed from the Program List of the SYSPRO menu:

- Program List > Return To Supplier

-

Triggers on Inspection

Return to Supplier is triggered when an item fails incoming or in-process inspection and needs to be returned to the supplier.

-

Links to Purchase Orders

The Return to Supplier document is linked to a purchase order to ensure full control of all information and traceability of the product history.

-

Return Material Authorization

Once agreement has been reached with the supplier on the nature of the defects and quantity of items to be returned, the Return Material Authorization (RMA) voucher is issued to the supplier, detailing the collection of the defective product.

-

Updates Inventory

Once the goods are held in a quarantine area and the defective material agreed for return, the items to be returned to the supplier are removed from the available stock, ensuring that stock is up to date.

-

Tracks Product Movement

As soon as a product is processed for return to its supplier, the system can track its exact position in the supply chain.

-

Cost Management, GRN, Credit Notes and Purchase Orders

Return to Supplier tracks variances between the cost of an item and the credit received. It allows for the creation of a GRN which can be matched against a supplier's credit note, and a purchase order for expected replacement items.

-

Reports

-

RTS Return Slip Print

Prints a return slip that remains with the goods as part of the return to supplier process for the supplier (to identify the defective goods).

-

RTS Returns Report

Keeps a record of all goods that have been returned in a specific period.

-

RTS Status Report

Tracks the status of the returns and where they are along the supply chain.

-

- Define the Key type and Case for RTS numbering.

- Define a default product class for non-stocked items that are returned to the supplier at the Non-stocked product class setup option.

- Select Create a credit for freight or handling to generate AP credit invoices for a supplier for freight and/or handling costs incurred by returning goods to the supplier.

- Define the ledger accounts to which RTS distribution entries are posted at the General ledger accounts setup options.

- Define the ledger accounts to which the GRN distribution entries are posted at the GRN suspense setup option.

-

If you've previously used the Return to Vendor system, you must run the RTS Conversion Check program from within SYSPRO 8 to use the Return to Supplier system.

-

Run the conversion by selecting the option and entering RTSUCC in the Program to run field.

The table names and program fields will be renamed during the conversion.

If you haven't run the conversion, you will be prompted to do the conversion when accessing any program that forms part of the Return to Supplier system.

You can return goods to suppliers by capturing a negative inventory receipt, by capturing a return merchandise authorization (RMA), by capturing a negative purchase order receipt or when capturing an RTS (when returning non-stocked goods).

-

Capture an RMA using the RMA Issues and Receipts program and create an RTS transaction from the RMA to return the goods to the original supplier using the RTS from RMA program.

or

Capture and post a negative stock receipt using the Inventory Movements program and capture the RTS using the RTS from Inventory Receipt program.

or

capture a negative purchase order receipt using the Purchase Order Receipts program.

or

Capture an RTS for non-stocked goods using the RTS Review program.

- Once created, search for and review RTSs using the RTS Review program. From this program you can do the following:

- Specify freight and handling charges using the RTS Maintenance program.

- Create a new or maintain an existing RTS using the RTS Maintenance program.

- Add notes to the RTS using the Notepad program.

Accept or reject and thereafter post the RTS using the RTS Maintenance - Allow and Reject program.

- When you accept the RTS a new purchase order is created.

-

Return slips can be printed individually using the RTS Return Slip Printing program or in batches using the RTS Return Slip Document Print program.

- RTS details can be viewed using the Return to Supplier Browse program.

- GRNs can be viewed using the Browse on GRNs program.

- Obsolete RTS's can be purged using the RTS Purge program.

The following indicates areas in the product that may be affected by implementing this feature:

This is a new program that lets you purge obsolete RTS transactions.

This is a new program that lets you capture the detail required to return stocked items to the supplier once they have been removed from the inventory.

This program can be accessed from the Inventory Movements program after posting a negative inventory receipt.

This is a new program that lets you create an RTS from an RMA when stocked or non-stocked items that are returned by the customer, will in turn be returned to your supplier.

This program can be accessed when ending the RMA in the RMA Issues and Receipts program; provided the correct selections were made when the receipting the RMA lines.

This is a new program that is displayed from the RTS Maintenance program when printing RTS return slips.

This program lets you create a new RTS when returning non-stocked items and/or maintain an RTS that was created using the RTS from Inventory Receipt program (accessed from Inventory Movements) or RTS from RMA program (accessed from the RMA Issues and Receipts).

This is a new program that lets you search for, view, maintain and action existing RTSs.

This is a new program that lets you browse RTS detail.

This is a new program that is displayed when you select Accept or Reject from the RTS Review pane of the RTS Review program.

This is a new program that lets you integrate the RTS journals to the General Ledger if automatic GL integration isn't enabled.

This is a new program that lets you generate and print RTS return slips that accompany the merchandise when it is returned to the supplier.

This is a new report that contains details of goods that were returned to suppliers.

This is a new report that lets you view and print RTS data and their current statuses.

This is a new report that lets you view and print RTS journal transactions.

This is a new business object that lets you query RTS data.

This is a new business object that lets you view the journals processed for RTS transactions.

This is a new business object that lets you query the status of an RTS.

This is a new business object that lets you print return slips for merchandise returned to the supplier.

An RTS purchase order update is processed when a receipt is posted.

You can now return stocked items to the supplier by posting a negative receipt. This loads the RTS from Inventory Receipt program for you to process the RTS inventory receipt.

The Return to Supplier option at the Inventory Action field lets you create an RTS for the return of stocked and non-stocked items to the supplier.

The RTS from RMA program is displayed when ending the RMA after selecting the Return to Supplier option at the Inventory Action field.

You can then capture the RTS detail.

The following indicates the possible status codes for an RTS transaction.

| Status | Description |

|---|---|

| N - Normal |

The RTS has been created. |

| A - Accepted |

The supplier has accepted the RTS and agreed to a credit or a replacement. |

| R - Rejected |

The supplier has rejected the RTS. |

Copyright © 2025 SYSPRO PTY Ltd.