You use this program at any time to view static details held on file against your stock items, as well as any transactions that have been processed against them.

If you are new to this query, then the following information will help you achieve the best results:

- The information shown is always up to date (i.e. the query reflects the latest information for stock items added or changed).

-

If you know the stock code, then you can enter it directly and press the Tab or Enter key to view the information.

If you do not know the stock code, then you can use the browse icon to locate the code.

-

You can personalize this query in a number of ways. These include:

- setting preferences that affect what information is displayed. These settings can be retained for future use

- configuring property sheets (e.g. the section headed Stock Code Details). This includes being able to sequence items by dragging them up or down, to show important items first

- configuring the Warehouse Values, Warehouse History and Movements listviews. This includes being able to sequence columns by dragging them left or right, sorting columns and changing column widths

- configuring the layout of the panes on the screen, including hiding or displaying panes

- Toolbar and menu

- Stock Code Details

- Distribution

- Production

- Warehouse Values

- Warehouse History

- Movements

- Notes

- User Defined

- Custom Form

- History of Usage

- Period Closing Balance

- Notes and warnings

| Field | Description | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Query | |||||||||||||||||||||||

| Multiple Bins | Select this to view bins for the stock item. This function is available only if you enabled the option: Multiple bins (Inventory Setup). |

||||||||||||||||||||||

| FIFO/LIFO Buckets | Select this to view FIFO or LIFO buckets for this

item. This function is available one of the following options is enabled:

|

||||||||||||||||||||||

| Lots | Select this to view lot traceability details for the

stock item. This function is available only if the stock code is defined as a traceable item (Stock Codes). |

||||||||||||||||||||||

| Reserved Parent Lots | Select this to use the Lot Traceability Parent Reservations program to view

reserved lot information for the stock item. This only applies if the stock code is defined as a lot traceable parent item (Stock Codes). |

||||||||||||||||||||||

| Serial Tracking | Select this to view serial number tracking information

for the stock item. This only applies if the stock code is defined as a serialized item (Stock Codes). |

||||||||||||||||||||||

| Reserved Parent Serials | Select this to view reserved serial information for the

stock item. This only applies if the stock code is defined as a serialized parent item (Stock Codes). |

||||||||||||||||||||||

| Alternate Stock Codes | Select this to view and maintain alternate stock codes that have been assigned to the stock item. | ||||||||||||||||||||||

| Goods in Transit | Select this to view the Goods in Transit details for

the selected stock item. This applies only if you enabled the option: Full goods in transit transfers facility (Inventory Setup). |

||||||||||||||||||||||

| Movements | Select this to view a detailed history of sales and inventory movements processed against the stock item. | ||||||||||||||||||||||

| Customer Stock X-Ref |

Select this to view and maintain any stock code interchange details held on file for a specific customer, or all customers. This only applies after a Stock code has been entered and accepted. You can, however, use the Find toolbar option to find a customer stock code cross reference before a Stock code is entered. You establish an interchange using the Customer Stock Codes program. This enables you to selectively link customers to specific SYSPRO stock codes. When the customer's stock code is entered during processing within the Sales Order Entry program, the system automatically extracts the SYSPRO stock code.

|

||||||||||||||||||||||

| Supplier Stock Code X-Ref | Select this to view and maintain a cross-reference between a SYSPRO stock code and a supplier catalogue number. | ||||||||||||||||||||||

| ATP |

Select this to view the available to promise details for a particular stock code/warehouse combination. You can view details of the individual supply and demand that affects the available to promise for the stock item, as well as time fence calculations that were performed (see Inventory ATP Query and Sample calculations). |

||||||||||||||||||||||

| Cost Analysis | Select this to view costs in a specific unit of measure for the stock item. See Inventory Cost Analysis Query. | ||||||||||||||||||||||

| Return Merchandise | Select this to view RMA transaction details processed against the stock item. | ||||||||||||||||||||||

| Sales | |||||||||||||||||||||||

| Sales Orders | Select this to view outstanding customer orders that have been placed for the stock item. | ||||||||||||||||||||||

| Forecast | Select this to view and maintain forecasts for the stock item. | ||||||||||||||||||||||

| Dispatch | Select this to browse on dispatch notes for an order. | ||||||||||||||||||||||

| Pricing | Select this to view and maintain the price codes and prices assigned to the stock item. | ||||||||||||||||||||||

| Quantity Breaks | Select this to view and maintain the quantity discount

breaks assigned to the stock item. This applies only if the pricing method defined for the stock item is defined as quantity discounted (Stock Codes). |

||||||||||||||||||||||

| Goods in Transit (Sales) | Select this to view the Goods in Transit details for

the selected stock item.

|

||||||||||||||||||||||

| Purchasing | |||||||||||||||||||||||

| Purchase Orders | Select this to view purchase orders that have been placed against the stock item. | ||||||||||||||||||||||

| Blanket P/Orders | Select this to view blanket purchase orders that have been placed against the stock item. | ||||||||||||||||||||||

| Requisitions | Select this to view requisition details captured for the stock item using the Requisition Query for Stock Code program. | ||||||||||||||||||||||

| Inspection | Select this to use the Inventory Goods in Inspection Query program to view

inspection details for this item. This applies only if the item has been defined as requiring inspection (Stock Codes). |

||||||||||||||||||||||

| Foreign Prices | Select this to view and maintain foreign price details for the stock item. | ||||||||||||||||||||||

| Alternate Suppliers | Select this to view and maintain alternate supplier details for the stock item. | ||||||||||||||||||||||

| LCT Routes | Select this to view all the shipping routes defined for the item. | ||||||||||||||||||||||

| Production | |||||||||||||||||||||||

| Work in Progress |

Select this to view information regarding work in progress jobs for the stock item. Although completed jobs are excluded from this function by default, you can use the Include menu to include details for completed jobs. |

||||||||||||||||||||||

| Allocations |

Select this to view material allocations of the stock item to jobs. Although completed allocations for jobs are excluded from this function by default, you can use the Include menu to include details for completed allocations. |

||||||||||||||||||||||

| ECC Quantities |

Select this to view quantities per revision/release per warehouse for the stock item. This function is available only for ECC-controlled items where the Stock control level is set to Revision or Release (Bill of Materials Setup). |

||||||||||||||||||||||

| ECC History |

Select this to display all the revisions/releases for the stock item you are querying. Select View Stock Information from the Function menu to view stock information for each revision/release. This function is available only for ECC-controlled items where the Stock control level is set to Revision or Release (Bill of Materials Setup). |

||||||||||||||||||||||

| Where Used |

Select this to query where a specific component stock item is used in the manufacturing process. If you enabled the option: Alternate routings (Bill of Materials Setup) then you can change the route. |

||||||||||||||||||||||

| Structure & Routing | Select this to view all operations and materials attached to the stock item. | ||||||||||||||||||||||

| Structure | Select this to view all materials attached to the stock item. | ||||||||||||||||||||||

| Routing | Select this to view all operations attached to the stock item. | ||||||||||||||||||||||

| Co-products | Select this to use the BOM Co-Product Maintenance program to view and

maintain co-products attached to a notional part. This option is only enabled when the item you are querying is defined as a Notional part (Stock Codes). |

||||||||||||||||||||||

| Build Schedule | Select this to view and maintain build schedules for

the stock item. This function is available only for MPS and Statistical items. |

||||||||||||||||||||||

| WIP Inspection |

Select this to view details of items that are in WIP inspection using the WIP Inspection Maintenance program. This option is only available if you enabled the option: Work in Progress inspection required (Work in Progress Setup) and the stock item you are querying is made-in and defined as traceable or inspection required (Stock Codes). |

||||||||||||||||||||||

| Material Requirements |

Select this to use the Requirements Planning Query program to view the results of the Requirements Calculation for the stock item. |

||||||||||||||||||||||

| Company Calendar | Select this to view and maintain the company calendar (see Company Calendar). | ||||||||||||||||||||||

| Stock code | Enter the stock code to query. Stock codes not inked to any warehouse are not displayed when you use the Browse icon if the option Filter based on operator access listInventory Setup is enabled. |

||||||||||||||||||||||

| Find | |||||||||||||||||||||||

| Find Stock Code | Select this to use the Key Search program to locate an item according to search criteria. | ||||||||||||||||||||||

| Supplier Stock X-Ref | Select this to use the Browse on Supplier Stock Code Cross Ref program to locate the cross-references between a SYSPRO stock code and a supplier catalogue number. | ||||||||||||||||||||||

| Customer Stock X-Ref | Select this to use the Customer Stock Code X-Ref for a Stock Code program to locate the links between a SYSPRO stock code and a customer stock code. | ||||||||||||||||||||||

| Approved Manufacturers | Select this to use the Browse on Approved Manufacturer Parts program to locate the approved manufacturers' part numbers for the stock code. | ||||||||||||||||||||||

| Browse in Last Sequence | Select this to use the Browse on Stock Codes program to browse on stock codes in the sequence defined in the Browse on Stock Codes listview. | ||||||||||||||||||||||

| Play | Displays any multimedia objects assigned to the item. | ||||||||||||||||||||||

| Edit | Select this to maintain multimedia objects for the item. | ||||||||||||||||||||||

| Bitmaps | Displays bitmap images assigned to your stock items. | ||||||||||||||||||||||

| Notes | Select this to view and maintain various text notations against the

stock item. A tick indicates that text is assigned to the

item.

|

||||||||||||||||||||||

| Field | Description |

|---|---|

| Stock code | This indicates the code of the stock item. |

| Description | This describes the stock code and is displayed throughout the system whenever the stock code is entered. You can use it to verify that the correct item has been entered. |

| Long description | This is an additional description assigned to a stock code which can be printed on reports and inventory documents. |

| Date of supersession | If the stock code's supercession date is before the current system date, then the supercession date is displayed in red. |

| Units of measure: |

|

| Product class (Browse on Product Classes) |

If you define product classes using the Product Classes program, without defining a branch code for the product class, then the product class description is displayed. If, however, you selected to view product classes by branch and defined the product class against a specific branch, then the product class description is not displayed. The reason is that you could define different descriptions for a single product class in the different branches. The product class description is retrieved from the SALPDS file/table. |

| ABC classification | This is displayed if you selected the option: ABC analysis required (Stock Codes) and you processed the ABC Analysis report for ALL warehouses. This classification therefore indicates the classification for the stock item based on the usage of the stock item in all warehouses (i.e. across the entire company). |

| Queries |

The following queries can be selected from this option:

|

| Field | Description |

|---|---|

| Tax information: | Tax code (see Browse on Tax Codes) |

| Supplier |

|

| Total usage | This is taken from the InvMovements table and is the sum of the transaction quantities of all transactions with a movement type of I (Issue/Receipt) and [transaction type I (Issues) or S (Sales)] for transactions which took place in the last year. |

| Stock turnover ratio | This is the Total usage value

divided by 365 if the stock was added a year or more ago.

If the stock was added less than a year ago, then it is the Total usage value divided by the number of days ago that the stock was added. For example, if the stock code was added on 1/1/2017, then on 1/2/2017 the stock code is 31 days old, so the Stock turnover ratio will be Total usage divided by 31. |

| Service charges | See SO Service Charge If a service charge is attached to this stock item, then you can use the Service Charges program to query the details of the service charge. |

| Queries |

|

| Column | Description |

|---|---|

| Work in Progress | See Inventory Browse on WIP for Stock Code |

| Structure & routing | See Structures and Routings |

| Allocations | See Inventory Browse on Alloc for Stock Code |

| Quotations | See Quotation Query for Stock Code |

| ECC change order | See ECC Change Order Browse by Stock Code |

| Revision/Release | See BOM Browse on ECC Rev Rel |

| Warehouse to use: |

|

| Bill of materials: |

These costs are updated when you change the costs associated with the specific item (manual cost) or when the cost implosion is run and changes in the cost of an item are rolled up to the parent part.

|

| Drawing number | This number is not necessarily the same number defined against the stock code in the Drawing Register. The drawing register number defined against the stock code in Stock Codes) is used for documentary purposes only and is not validated against the ECC Drawing Register/Stock code combination. When the Drawing number against the stock code is changed, the Drawing Register is not updated. |

| Queries |

See Activity considerations in Notes and warnings. |

You use the options in the Warehouse Values Selection pane to indicate your preferences for this tab (see Warehouse Values Selection).

You can switch the Smart Link on the listviews on and off by pressing Alt + Shift + F7.

| Column | Description |

|---|---|

| Available |

The quantity available is the quantity on hand less the quantity allocated to sales orders for the item in the selected warehouse. The quantity allocated to sales orders is the order quantity and includes quantities on backorder. The quantity available includes stock on hold, stock in expired lots, stock locked by Engineering Change Orders and stock in bins that are on hold. The reason is that the quantity on hand (used in the calculation) is the quantity physically in the warehouse and includes quantities on hold. |

| Unallocated | Calculated as: (quantity on hand - allocated to sales orders - allocated to work in progress - quantity reserved for WIP allocations) |

| On hand | This indicates the quantity of the item physically in the warehouse. This includes quantities on hold. |

| In inspection | This indicates the quantity of purchased items awaiting inspection (i.e. receipted into inspection but not receipted into stock). |

| In transit | This indicates the outstanding non-immediate warehouse transfers shown against the target warehouse. |

| On order | This indicates the quantity of outstanding purchase orders, made-in jobs and supply chain transfers. |

| Allocated to sales orders |

Calculated as: (quantity on back order + sales order ship quantity). These quantities exclude unallocated scheduled order back order and ship quantities and the quantity reserved for WIP allocations. Manual serial tracked items that are either in service or on loan items, are accumulated to this quantity to prevent the selling of those items. See Inventory > Serial Tracking System > Transaction Posting. Note that the ship quantities for credit notes are NOT included in the sales order ship quantity. Credit note quantities are never included in the allocations as these quantities are only available once the credit has been fully processed. |

| WIP Qty reserved |

Indicates the quantity reserved for a material allocation against a confirmed job. This is the WIP Reserved quantity (QtyWipReserved) in the Inventory warehouse table (InvWarehouse). This quantity is only displayed when reserving at stock code level, not at lot level. When reserving components at lot level, the reserved quantities can only be checked against the lot records, which can be viewed using the Lots browse from the Query menu. This applies only when the Reserve stock for allocations (Work in Progress Setup) is enabled. When reserving components at lot level, the reserved quantities can only be checked against the lot records and these are viewable in the Lots browse from the Inventory Query. |

| On back order | This indicates the sales order back order quantity. This quantity excludes unallocated scheduled order back order quantities. |

| Allocated to WIP |

This indicates the outstanding materials to be issued to jobs. This includes allocations to both confirmed and unconfirmed jobs. |

| Future free | Calculated as: (quantity on hand + quantity in inspection + quantity in transit + quantity on order - allocated to sales orders - allocated to work in progress - quantity reserved for WIP allocations) |

| ABC class | This is displayed if you selected the option: ABC analysis required (Stock Codes) and you processed ABC Analysis report for this specific warehouse. This classification therefore indicates the classification for the stock item based on the usage of the stock item in this specific warehouse only. |

| Dispatched not invoiced | This indicates goods delivered on a dispatch note, but not yet invoiced. |

| Landed cost multiplier | This indicates the value of the cost multiplier defined against the warehouse for this stock item (Inventory Warehouse Maintenance for Stock Code). |

| RMA inspection | This indicates the total quantity currently in inspection as a result of RMA receipts. |

| YTD usage value | This is an annualized figure and is always based on the last 12 periods usage. It is not cleared at year end. The YTD usage value is increased in the period by all sales as the invoices are processed (i.e. at the cost used at the time the invoice was processed). Similarly issues update this value at the time of the issue. Thus, during a month this figure is the last calculated usage from the month-end process plus any movements that have taken place during the month. The year to date usage value is updated perpetually. It is updated during the month by programs such as Document Print, which takes the cost value of the stocked lines as they are invoiced, and adds this to the YtdUsageValue field. It is updated for each warehouse as follows when the Month end or Year end function of the Inventory Period End program is run:

At the Inventory month end you will now have a figure that represents 13 months information, as it is divided by 13 and multiplied by 12 to give the annualized value The ABC Analysis program uses the usage value to classify stock items into A, B, C or D class items. See also YTD usage value example. |

Following is an example of how the Annual usage value is used to classify stock items starting with a new stock code.

| Month 1 | Sales = 100 | Total = 100 | Month end - no action | ABC report calcs as 100 / 1 * 12 = 1200 |

| Month 2 | Sales = 120 | Total = 220 | Month end - no action | ABC report calcs as 220 / 2 * 12 = 1320 |

| Month 3 | Sales = 120 | Total = 340 | Month end - no action | ABC report calcs as 340 / 3 * 12 = 1360 |

| Month 4 | Sales = 110 | Total = 450 | Month end - no action | ABC report calcs as 450 / 4 * 12 = 1350 |

| Month 5 | Sales = 120 | Total = 570 | Month end - no action | ABC report calcs as 570 / 5 * 12 = 1368 |

| Month 6 | Sales = 120 | Total = 690 | Month end - no action | ABC report calcs as 690 / 6 * 12 = 1380 |

| Month 7 | Sales = 110 | Total = 800 | Month end - no action | ABC report calcs as 800 / 7 * 12 = 1371 |

| Month 8 | Sales = 120 | Total = 920 | Month end - no action | ABC report calcs as 920 / 8 * 12 = 1380 |

| Month 9 | Sales = 120 | Total = 1040 | Month end - no action | ABC report calcs as 1040 /9 * 12 = 1387 |

| Month 10 | Sales = 130 | Total = 1170 | Month end - no action | ABC report calcs as 1170 / 10 * 12 = 1404 |

| Month 11 | Sales = 120 | Total = 1290 | Month end - no action | ABC report calcs as 1290 / 11 * 12 = 1407 |

| Month 12 | Sales = 100 | Total = 1390 | Month end - no action | ABC report uses 1390 |

| Year end - no action | ||||

| Month 1 of the next year | Sales = 150 | Total = 1540 | Month end calculation - 1540 / 13 * 12 = 1422 | ABC report uses 1422 |

| Month 2 of the next year | Sales = 110 | Total = 1532 | Month end calculation - 1532 / 13 * 12 = 1414 | ABC report uses 1414 |

The Annual usage value = Usage brought forward from previous period end plus ((quantity issued x cost) + (quantity sold x cost) for the current period to date). The cost at the time the transaction was processed is used, not the current cost.

The annual usage value of a stock item is used to determine its classification. This value is the total cost of sales and issues of an item over the past 12 months.

The program calculates the total inventory usage value by accumulating the annual usage value for each warehouse. It then calculates the annual usage value for each stock item.

The annual usage value (A.u.v) is increased in a period by the sales values as invoices are processed. The cost used at the time that the invoice was processed is used. Similarly, the total inventory usage is updated when the item is issued. Therefore, during a specific period, the YTD usage is the usage as at the previous period end, plus the usage from movements that have occurred during the current period.

For each month end after the 12th month, the usage value is annualized by dividing the value by 13 and multiplying by 12. If the annual usage value of a stock item is based on less than 12 months history, then the value is divided by the number of months that the item has been held on file, and multiplied by 12 to give an annual usage value.

The information displayed in this pane relates to the currently highlighted line in the Warehouse Values listview.

| Column | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Quantity on hand | This indicates the quantity of the item physically in the warehouse. This includes quantities on hold. | ||||||||||

| Quantity on backorder | This indicates the sales order back order quantity. This quantity excludes unallocated scheduled order back order quantities. | ||||||||||

| Quantity allocated to S/O |

Calculated as: (quantity on back order + sales order ship quantity) These quantities exclude unallocated scheduled order back order and ship quantities. Note that the ship quantities for credit notes are NOT included in the sales order ship quantity. Credit note quantities are never included in the allocations as these quantities are only available once the credit has been fully processed. |

||||||||||

| Quantity available |

The quantity available is the quantity on hand less the quantity allocated to sales orders for the item in the selected warehouse. The quantity allocated to sales orders is the order quantity and includes quantities on backorder.

|

||||||||||

| Quantity in inspection | This indicates the quantity of purchased items awaiting inspection (i.e. receipted into inspection but not receipted into stock). | ||||||||||

| Quantity on order | This indicates the quantity of outstanding purchase orders, made-in jobs and supply chain transfers. | ||||||||||

| Quantity allocated to WIP | This indicates the quantity of materials (components) and labor allocated to the job. This is displayed regardless of whether the job is confirmed or not. | ||||||||||

| Future free | Calculated as: (quantity on hand + quantity in inspection + quantity in transit + quantity on order - allocated to sales orders - allocated to work in progress) | ||||||||||

| Quantity dispatched not invoiced | This indicates goods delivered on a dispatch note, but not yet invoiced. | ||||||||||

| Graphs |

|

||||||||||

| Costs |

|

||||||||||

| Company |

This indicates the company for which the values are being displayed. This is only displayed if you selected the Multiple Company Values option. |

||||||||||

The options in this pane enable you to indicate your preferences for the listview on the Warehouse Values tab.

| Field | Description | ||||

|---|---|---|---|---|---|

| Refresh Warehouse Values | Select this to redisplay the information on the

Warehouse Values tab to reflect changes you made to the

options in this pane. This function is only enabled when you make a change to the selections. |

||||

| Autoload Values | These options enable you to indicate how you want to save the

selections made in this pane. You can choose to set all selections as they were when you last ran the program (i.e. Load Previous Form Values) or save your selections in the pane as your default preferences for all companies, or for the current company only (i.e. Save Form Values as Default or Save Form Values for this Company). If you have saved form values for the company or as the default, then you can remove these settings and restore them to the form's default preference selections. |

||||

| Warehouses | |||||

| Combine warehouses |

Select this to accumulate the values held in all selected warehouses for the stock item.

|

||||

| Warehouse selection | This enables you to indicate which warehouse(s) to

display and the specific information to display.

|

||||

| List of warehouses | Select the Define List option to use the Generic Define List of Items program to define a list of warehouses for which to display the information or to select a previously saved list. | ||||

| Multiple Company Values | Select this to view Warehouse

Values for multiple companies. This option is only enabled if:

|

||||

| Include | Indicate the items to display in the query based on

various criteria related to the items. Items with the following criteria can be selected/deselected for inclusion in the query:

|

||||

You use the options in the Warehouse History Selection pane to indicate your preferences for this tab (see Warehouse History Selection).

Details that can be viewed in this pane relate to the currently highlighted line in the Warehouse History listview.

| Column | Description |

|---|---|

| Company |

This indicates the company for which the values are being displayed. This is only displayed if you selected the Multiple Company Values option. |

| Warehouse | This indicates the warehouse for which the values are displayed. Combined indicates that the values are either the totals for all warehouses or for a list of warehouses as defined in the Warehouse History Selection pane. |

| Prev 1-12 sold/issued | These indicate the last 12 months' quantities sold and issued out of the warehouse. These values balance to the Usage fields M-12 through to M-01 on the Purchasing Work Sheet for the corresponding months. |

The options in this pane enable you to indicate your preferences for the listview on the Warehouse History tab.

| Field | Description |

|---|---|

| Refresh Warehouse History | Select this to redisplay the information on the

Warehouse History tab to reflect changes you made to the

options in this pane. This function is only enabled when you make a change to the selections. |

| Autoload Values | These options enable you to indicate how you want to save the

selections made in this pane. You can choose to set all selections as they were when you last ran the program (i.e. Load Previous Form Values) or save your selections in the pane as your default preferences for all companies, or for the current company only (i.e. Save Form Values as Default or Save Form Values for this Company). If you have saved form values for the company or as the default, then you can remove these settings and restore them to the form's default preference selections. |

| Warehouses | |

| Combine warehouses |

Select this to accumulate the values held in all selected warehouses for the stock item. This option applies to the Warehouse History tab only. |

| Warehouse selection | Indicate the warehouse(s) to view and the specific

information to display. You can only view details for warehouses to which you have access (Operators). The warehouse code is not validated when you select a single warehouse. Nothing is displayed in the listview for an invalid warehouse. |

| List of warehouses | Select the Define List option to use the Generic Define List of Items program to indicate a list of warehouses for which to display the information or to select a previously saved list. |

| Multiple company values | Select this to view Warehouse

History for multiple companies. This option is only enabled if:

|

You use the options in the Movements Selection pane to indicate your preferences for this tab (see Movements Selection).

Movements are displayed within each warehouse. This is irrespective of your selection at the Combine warehouses option (see Warehouse Values Selection and Warehouse History Selection).

| Field | Description |

|---|---|

| More lines | Select this to display the next set of lines as per

your selection at the Rows

option. This option is not enabled when you select to display all rows. |

| View journals | Select this to view information on the Inventory journals for the line currently highlighted in the Movements listview. Journals for Dispatch notes are also displayed where relevant. No other sales movement journals are displayed. |

| Rows | Indicate the number of rows to display in the listview. |

![[Note]](images/note.png)

|

|

|

When you drag a column into the listview, you need to refresh the stock code for the details in that column to be loaded. |

|

| Column | Description |

|---|---|

| Date | For Purchase Order receipts, this reflects the calendar date of the movement and not the start date when the Purchase Order Receipts program was loaded to process the receipt, unless the operator manually changed the date when processing the receipt. |

| Unit cost | This indicates the cost that was used to post the transaction, except when FIFO costing is used. In this case, the cost is not displayed as more than one FIFO bucket may have been used for the transaction. |

| Unit price/New cost |

The Unit price is the price expressed in terms of the stocking unit of measure for the item. The New cost is the warehouse cost after the transaction was processed. For Standard costing, the Unit cost and the New cost will be the same. For other costing methods, these two values may or may not differ. |

| New wh | This column displays the destination warehouse for GIT (Goods in Transit) transfers. |

| Lot | This is only used if you are using Actual costing (Inventory Setup). It is updated from the LotSerial field in the InvMovements table. |

| Default warehouse |

This column applies if a default warehouse is assigned to your operator code (Operators - Defaults). When you add this column to the listview using the Field Chooser option, you can view movements for your default warehouse first, by sorting the listview on the Default warehouse column. |

| Inv/Ref |

This is used to display one of the following:

For a Dispatch note, the movement is written when the dispatch note is created (i.e. when the stock actually moves). There is no direct way to pick up the movement to update it when the Dispatch invoice is processed, so no invoice number is displayed for Dispatch notes. |

| Customer purchase order | Indicates the customer's purchase order number. It is linked only to a customer and not to a warehouse. It is therefore not displayed for SCTs. |

The options in this pane enable you to indicate your preferences for the listview on the Movements tab.

| Field | Description | ||||

|---|---|---|---|---|---|

| Refresh Movements | Select this to redisplay the information on the

Movements tab to reflect changes you

made to the options in this pane. This function is only enabled when you make a change to the selections. |

||||

| Autoload Values | These options enable you to indicate how you want to save the

selections made in this pane. You can choose to set all selections as they were when you last ran the program (i.e. Load Previous Form Values) or save your selections in the pane as your default preferences for all companies, or for the current company only (i.e. Save Form Values as Default or Save Form Values for this Company). If you have saved form values for the company or as the default, then you can remove these settings and restore them to the form's default preference selections. |

||||

| Movements selection | |||||

| Movements display | These options refer to the warehouse order in which

the movements are displayed in the Movements

listview. Irrespective of the order you select the movements are displayed within each warehouse in the following order: Earliest year, then earliest period, then earliest transaction date and lastly earliest transaction time. |

||||

| Earliest movements first | Select this to display the stock movements from the first warehouse to the last warehouse in alphabetic/numeric sequence. | ||||

| Latest movements first | Select this to display the stock movements in reverse

key sequence, which is from the last warehouse to the first

warehouse in alphabetic/numeric sequence. If you restricted the number of rows to display, the highest warehouse in alphabetical/numerical order is displayed first. Only by selecting the More Lines option will the additional movements be displayed. |

||||

| Movement sequence | |||||

| Warehouse, date | Select this to display the stock movements in date sequence (earliest or latest) within each warehouse. | ||||

| Date | Select this to display the stock movements in date sequence (earliest or latest) ignoring the warehouse sequence. | ||||

| Warehouses | |||||

| Warehouse selection | Indicate the warehouse(s) for which to display

information in the Movements tab

listview.

|

||||

| List of warehouses | Select the Define List option to use the Generic Define List of Items program to define a list of warehouses for which to display the information or to select a previously saved list. | ||||

| Movement dates | Indicate the date(s) for which to display movements

in the Movements tab listview. One of the following options can be selected:

|

||||

| From movement date | Indicate the first date in a range of dates for which

to display movements. If you selected to display movements for a single day then you enter that day in this field. When you select to display movements for Today, Today and Yesterday or This week, then you can optionally change the default date displayed. |

||||

| To movement date | Indicate the last date in a range of dates for which

to display movements. When you select to display movements for Today, Today and Yesterday or This week, then you can optionally change the default date displayed. |

||||

| Inventory transaction values | |||||

| Transaction value selection | Indicate the value(s) for which to display movements in the Movements tab listview. | ||||

| From transaction value | Indicate the lowest (or the single) value in a range of values for which to display movements. | ||||

| To transaction value | Indicate the highest value in a range of values for which to display movements. | ||||

| Options | |||||

| Customer | Indicate a single customer for whom to display movements. | ||||

| Supplier | Indicate a single supplier for whom to display movements. | ||||

| Salesperson | Indicate a single salesperson for whom to display movements. | ||||

| Purchase order | Indicate a single purchase order for which to display movements. | ||||

| Sales order | Indicate a single sales order for which to display movements. | ||||

| Sales movements | Select the types of sales movements you want to view

for each item in the Stock Movements listview of the query.

The following types of sales movements can be selected/deselected for inclusion in the query:

|

||||

| Inventory movements | Select the types of inventory movements you want to

view for each item in the Stock Movements listview of the

query. inventory movements are processed using the Inventory Movements program. The following types of inventory movements can be selected/deselected for inclusion in the query:

Only those inventory movements selected are displayed in the query. |

||||

The first three lines of each Note type are displayed in this section. You can view and edit the notes by clicking on a line of text. You can also use the Notes option from the toolbar to edit these notes.

This pane displays details of any custom form data that has been assigned to the item (Custom Forms Entry).

-

Custom Form Data Entry

Select this to use the Custom Form Data Entry program to enter custom form data against the stock item.

This graph displays a history of sales/issues of the item for the combined warehouses.

This graph displays a history of closing balance figures for the combined warehouses.

-

The number of decimals displayed in this query depend on your entry at the fields:

- Edit quantities using decimals (Company Maintenance)

- Maximum number of decimals (Stock Codes)

Operator access to the following activities within this program can be restricted. You configure this using the Operators program.

| Activity | Description | ||||

|---|---|---|---|---|---|

| BOM Access to Structure & Routings |

Controls whether an operator can:

|

||||

Operator access to the following fields within this program can be restricted. You configure this using the Security Fields function of the Operators program.

| Field | Description | ||||

|---|---|---|---|---|---|

| INV Text technical spec | Controls whether an operator can edit technical specification text against a stock item. | ||||

| INV Text sales order | Controls whether an operator can edit sales order text against a stock item. | ||||

| INV Text purchase order | Controls whether an operator can edit purchase order text against a stock item. | ||||

| INV Text job narrations | Controls whether an operator can edit job narration text against a stock item. | ||||

| INV Text inspections | Controls whether an operator can edit inspection text against a stock item. | ||||

| INV Text dangerous goods | Controls whether an operator can edit dangerous goods text against a stock item. | ||||

| INV Show costs in Inventory/WIP queries |

Controls whether stock item costs are displayed in the Inventory, Work in Progress, Projects and Contracts and Inventory Planning modules. It also controls whether cost values are printed on the Stock Take Variance report and the unit cost for bought out items is printed on the Advanced Trial Kitting (Legacy) report.

|

||||

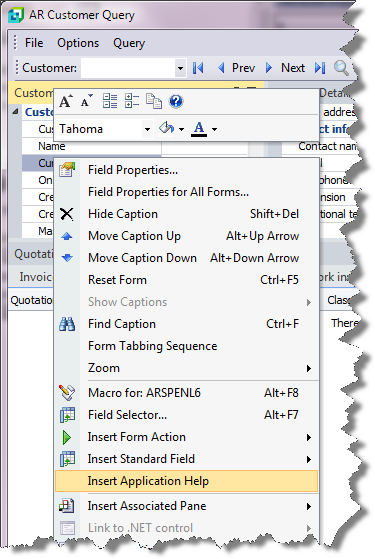

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.