You use this program to maintain the integrity of data in your Work in Progress module, to close the current month and open up a new month for processing your work in progress transactions and to delete work in progress information that is no longer required in the system.

This is achieved through the following functions:

- Balance

- Month end

- Year end

- Purge

- Labor period end

- Toolbar and menu

- Information

- Report

- Balance

- Month End

- Year End

- Purge

- Shared Inventory

- Notes and warnings

| Field | Description |

|---|---|

| Start Processing | Process the function you selected. |

| Print the information currently displayed in the Report pane. | |

| Save Form Values | This option is only enabled in Design mode (Automation Design). Your selections are saved and applied when the

program is run in automated mode. Form values and defaults are applied at operator level. They are not saved at role or group level. |

| Field | Description | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Current month number | This indicates the current month number of your Work in Progress module. | ||||||||||||||||

| Period end date | This indicates the period end date for the current month as defined in the Work in Progress Setup program. | ||||||||||||||||

| Last date balance was run |

This indicates the date on which the Balance function was last run. |

||||||||||||||||

| Processing options |

|

||||||||||||||||

| Function | Indicate the processing function to

perform. See also: Notes and warnings.

|

||||||||||||||||

| Inventory | |||||||||||||||||

| Company(s) | This indicates all the companies that share the current company's inventory file (Company Maintenance). | ||||||||||||||||

| Warehouse selection | Indicate the warehouse(s) for which to perform the selected function. | ||||||||||||||||

| Validate inventory allocations | Validate the Inventory on order quantity allocations for the warehouses selected. | ||||||||||||||||

| Options | |||||||||||||||||

| Include balance function |

This lets you choose whether you want to run the Balance function when you run a Month end or Year end function (i.e. it does not apply when processing the Balance or Purge only functions). This option is ticked automatically if the Last date balance was run field does not reflect today's date. This could have implications when using the Automation Design program where, for example, you don't want to run a Balance function before running another function. See also: Notes and warnings. |

||||||||||||||||

| Recreate dynamic capacity profile file | The dynamic capacity profile file comprises details of the capacity load for all jobs. Enable this to apply the outstanding capacity required for each operation evenly over the number of days available.This only applies when Work in Progress load levelling is required (Work in Progress Setup).

|

||||||||||||||||

| Update stock descriptions | Enable this to update the stock code descriptions held against a job if the description was subsequently changed against the inventory master file. | ||||||||||||||||

| Update customer name | Enable this to update the customer description held against a job if the description was subsequently changed against the customer master file. | ||||||||||||||||

| Reset detail line counter on job master | This option can be used if the next detail line of jobs is out of sync with the line number to use against the WIP job posting detail table. When enabled, the next detail line field on the Job master file/table is updated based on the last job posting detail line written on the WipJobPost table for each job. This option only applies when running the Balance function. |

||||||||||||||||

| Balance lot quantity reserved | Enable this to balance and update the reserved Lot quantity for allocations for completed allocations. The QtyReserved field in the LotDetail table is updated by totalling all WipAllMatLot records for each Stock code, Lot and Warehouse Bin combination. This only applies to the Balance function and when the Reserve stock for confirmed jobs option is enabled (Work in Progress Setup). |

||||||||||||||||

| Purge | |||||||||||||||||

| Jobs completed before |

This indicates the cut-off date according to which completed jobs will be removed from the system.

|

||||||||||||||||

| Scrap analysis dated before | This indicates the cut-off date according to which scrap analysis records will be removed from the system. | ||||||||||||||||

| Non-prod analysis dated before | This indicates the cut-off date according to which non-productive analysis records will be removed from the system. | ||||||||||||||||

| P&C contracts completed before | This indicates the cut-off date according to which completed contracts from the Projects and Contracts module (see Browse on Contracts) will be removed from the system. | ||||||||||||||||

| Warning messages | |||||||||||||||||

| Suppress warning messages |

When enabled, warning messages are ignored and do not cause the program to stop. When not enabled, processing stops and the warning messages are displayed in the Task Messages pane. |

||||||||||||||||

| After processing completed |

These options are displayed within programs that can be automated. They enable you to indicate the action you want to perform once processing is complete (see Automation Design). |

||||||||||||||||

| Purge details | These details relate only to the

Purge function and are displayed for

information purposes only. Refer to Purge for additional information. |

||||||||||||||||

This pane displays the results of the processing function you selected once processing is complete (unless you selected the option to close the application from the After processing completed section).

If you selected a Balance, Month end or Year end function, then the total outstanding WIP value is printed on the report produced when processing is complete. The total outstanding WIP value is the value of Work in Progress stock on the shop floor plus any variances from completed jobs.

To clear the variances from completed jobs you can use the Job Closure program for jobs for Stocked items and the Part Billings program for jobs for Non stocked items.

The system performs the following routine for a Balance:

-

Labor journals that were left in process (i.e. the program terminated abnormally during the posting of the journal) are reset.

-

The on order and work in progress allocation fields for the warehouse(s) selected are set to zero.

-

For all companies that share the inventory files, the outstanding quantity to manufacture for all incomplete stocked item jobs for the warehouse(s) selected is added to the on order field on the inventory warehouse record.

-

For all jobs excluding notional jobs, the material and labor costs to date are recalculated from the accumulated costs in the material and labor allocations for the job and compared to the value on the Job Header record. For a Notional job, the program calculates the quantity manufactured on the job header using the ratio of the quantity to make for co-products to the quantity manufactured for the co-products.

The Job Header record is updated with the calculated result if the values do not correspond. The difference and the value to which the Job Header record was updated are printed on the report generated by the WIP Period End. The next operation number to use is also regenerated. This is calculated as the highest operation number on file plus one.

Subcontract operations are included in the material costs, not the labor costs.

-

For each job, any outstanding material allocations for the warehouse(s) selected are added to the WIP allocation field on the inventory warehouse record.

-

All reserved stock for completed allocations is released. This applies when the Reserve stock for confirmed jobs option is enabled (Work in Progress Setup) and stock was reserved for the allocation. Note that when setting a job to complete, all allocations are automatically set to complete.

In addition, the reserved Lot quantity for allocations for completed allocations is balanced and the Lot quantity for allocations for completed allocations is updated (if required) when the Balance lot quantity reserved option is enabled.

-

The current value outstanding on each WIP Inspection Header record is recalculated by accumulating the transaction values on the attached Transaction Details records. If the resultant value is non-zero, then the inspection reference is set to incomplete to allow the value outstanding to be posted.

Material quantity issued on the material allocation file (WIPMAL) is the sum of all quantities issued to the allocation - held on the WIP posting details file (WIPPST).

Material value issued on the material allocation file (WIPMAL) is the sum of value of material issued to the allocation - held on the WIP posting details file (WIPPST).

Labor time issued on the labor allocation file (WIPLAL) is the sum of the relevant times (setup, startup, run, teardown) issued to the allocation - held on the WIP posting details file (WIPPST).

Capacity issued on the work center file (BOMWRK) is the sum of times issued to the labor allocations multiplied or divided by the factor.

The following fields are updated on the job header:

- Hours booked to date - Sum of all hours issued held on the WIP labor allocations

- Material cost to date - Sum of the value issued held on the WIP material allocations

- Labor cost to date - Sum of value issued held on WIP labor allocations

- Material issues to date - Sum of material costs distributed on the part bookings records (WIPPBK)

- Labor issues to date - Sum of labor costs distributed on the part booking records (WIPPBK)

- Quantity manufactured - Sum of quantity received in on the part booking records (WIPPBK)

- Labor value issued - Sum of value issued on the part booking records - rolled up from WIPPST.

-

If the Purchase Order module is installed, then the quantity outstanding for stocked lines matching the warehouse(s) selected from all purchase orders in a status of 1 (ready to print) or 4 (printed) are added to the on order field on the inventory warehouse record.

-

If required, the dynamic capacity profile file is recreated.

-

A summary report is printed indicating a breakdown of total jobs by status.

The system performs the following routine for a Month end:

-

Labor journals that were left in process (i.e. the program terminated abnormally during the posting of the journal) are reset.

-

If you indicated that your previous month must be closed automatically (Company Maintenance) then the current month is set to a status of closed. Otherwise the second previous month is set to a status of closed.

-

The current system date is moved to the month end date for the closing financial month.

-

The closing financial month number is incremented by one.

-

The new current financial month is set to a status of open.

-

A summary report is printed indicating a breakdown of total jobs by status.

The system performs the following routine for a Year end:

-

All the steps outlined in the Month end function are processed.

-

The current financial month number is reset to 1.

-

The current financial year is incremented by 1.

-

The current year's next labor posting journal number, next part billing journal number, month end dates and open/closed flags are moved to the previous year.

-

The next labor posting journal number and part billing journal number for the new year is set to 1.

-

The new year's month end dates are all set to zero.

-

The first month of the year (which is now the current month) is set to a status of open.

-

A summary report is printed indicating a breakdown of total jobs by status.

A purge can be run together with either a month end or year end, or as a separate process.

![[Note]](images/note.png)

|

|

|

The calculations for purging Labor posting journals, Part billing journals and Job amendment journals are based on the current financial year and posting period in Work in Progress and not on the current date. |

|

The system performs the following routine when doing a Purge:

-

Jobs and inspection references (see WIP Query), are archived if you selected the option: Archive completed jobs before purging (Work In Progress Setup).

Jobs are purged if they adhere to all of the following criteria:

- the job is complete

-

the job completion date is earlier than the purge cut-off date.

The purge cut-off date is either:

-

the date specified at the Jobs completed before field above

-

calculated by the system according to the number of days to retain completed jobs if this is specified (Work In Progress Setup).

-

- the work in progress value for the job is zero for the current month and previous 2 months. That means all the material and labour costs and issues in all the 'cost buckets' for the past three periods must be zero (i.e. the net value of the job itself must be zero).

- for jobs that are master jobs, all the sub jobs are complete

- there is no balance in the WIP inspection variance account for the job

If job amendment journals are required (Work in Progress Setup) then an amendment journal is created for each job deleted by the WIP Period End program.

-

WIP Inspection documents are deleted when the job is purged. Note that this is irrespective of whether they have been printed.

WIP inspection documents are only created if WIP Inspection is required (Work in Progress Setup).

-

Scrap records are deleted if the transaction date is earlier than the purge date entered. Scrap records are ignored if you selected the option: Permanently retain scrap analysis (Work In Progress Setup).

-

Non-productive records are deleted if the transaction date is earlier than the purge date entered. Non-productive records are ignored if you selected the option: Permanently retain non-productive analysis (Work In Progress Setup).

-

Labor posting journals are deleted if they adhere to the following criteria:

- the General Ledger journals for the labor posting transactions have been created (WIP Labor GL Integration)

- the General Ledger journals for the labor posting transactions have been posted (GL Journal Entry)

- the journals have been retained for the required number of months specified in the Number of months to retain - Labor posting journals field (Work In Progress Setup).

-

Part billing journals are deleted if they adhere to the following criteria:

- the General Ledger journals for the part billing transactions have been created (WIP Part Billings GL Integration)

- the General Ledger journals created for the part billing transactions have been posted (GL Journal Entry)

- the journals have been retained for the required number of months specified in the Number of months to retain - Part billing journals field (Work In Progress Setup).

-

Reserved lots and serials are deleted when the jobs for which they were reserved are purged.

-

_TMP jobs created in the Job Entry and Quotation Job Loading programs are deleted if there was a system crash during the process of their creation and deletion.

-

Custom form data associated with a job is deleted when the job is purged.

-

Job amendment journals are deleted for archived, completed, and deleted jobs when the job amendment journal date is earlier than the date calculated backwards from the current WIP Period minus the Number of months to retain job amendment journals indicated in the Work In Progress Setup program. No job amendment journals are deleted when the Number of months to retain job amendment journals is set to 99.

This procedure describes how to perform a day end when Inventory is shared between two SYSPRO companies.

Automating the process is recommended as this allows you to determine the sequence of steps, provide reporting and the system does not have to wait for the operator to initiate the next step (See Automation Design).

It is suggested that a specific operator is created (e.g. a Day-End operator) and set the tick-over rate for reports and batches to as long as possible (Operators). A tick-over rate of 1000 seconds is not as lively as a per second setting, but also not so sluggish that it is not apparent whether the program is running or hanging. For best performance the higher the value the better.

The sequence of running the programs is important.

-

In your main company (the company with the Inventory master) run the Purchase Order Purge program and ensure you select either the Validate Inv on order quantity option or the Purge and validate function (not the Purge only).

This will balance the purchase orders as well as the dispatch notes back to the stock code warehouse file.

You only need to run this in the main company, not the secondary company; the secondary company will merely re-run the main company.

-

Run the WIP Period End program.

Ensure that the Validate inventory allocations option is unchecked; the same functions have already been performed in the Purchase Order Purge program.

Inventory allocations will already be balanced for the jobs (parents and components). The Validate inventory allocations option does a full Inventory balance (e.g. Dispatch notes).

If you know that your stock code descriptions and customer names have not changed (or you feel these are irrelevant because they are only used on internal documentation) then uncheck the Update stock code descriptions and Update customer name options.

-

Run the WIP Balance function in the secondary company with the same selection criteria as the main company.

If you want to run a day end or a week end, then run the Balance function. If you want to do a month end, then run a Balance function and then a Month end.

-

It is strongly recommended that you take a backup of your data before processing a Month end, a Year end or a Purge.

-

To prevent data imbalances occurring, it is advisable to either process a Balance function immediately before processing any Month end or Year end function, or to enable the Include balance function option when processing any Month end or Year end function.

The following warning message is displayed if the current date is not the same as the date displayed in the Last date balance was run field: Imbalances may occur if you continue as the 'Balance' function has not been run today. Do you wish to continue?

-

You cannot process the following transactions if the Work in Progress and the Inventory modules are not in the same month and year:

- Job Receipts (Job Receipts)

- Backflushing (Inventory Movements)

- Job/Kit Issues (Job Issues)

- Issue floor stock allocations (WIP Issue Floor Stock Allocations)

- Accept into stock from WIP inspection (WIP Inspection Maintenance)

- Scrap items from WIP inspection (WIP Inspection Maintenance)

- Rework items from WIP inspection (WIP Inspection Maintenance)

-

The following fields are not saved when using the Save Form Values:

-

Information section

-

Current month number

-

Period end date

-

Last date balance was run

-

-

Purge section

-

Jobs completed before

-

Scrap analysis dated before

-

Non-prod analysis date before

-

P&C Contracts completed before

-

-

Purge details section

These options are hidden according to the options defined in Work In Progress Setup.

-

Labor posting journals dated before

-

Part billings journals dated before

-

Printed labor distributions dated before

-

Printing billing distributions dated before

-

-

Electronic Signatures provide security access, transaction logging and event triggering. This enables you to increase control over your system changes.

Access to the following eSignature transactions within this program can be restricted at Operator, Group, Role or Company level. You configure this using the eSignature Setup program.

| eSignature Transaction | Description |

|---|---|

| WIP Period end run - Balance |

Controls access to the Balance processing function in the WIP Period End program. |

| WIP Period end run - labor period end |

Controls access to the Labour period end processing function in the WIP Period End program. |

| WIP Period end run - month end only |

Controls access to the Month end only processing function in the WIP Period End program. |

| WIP Period end run - month end and purge |

Controls access to the Month end and purge processing function in the WIP Period End program. |

| WIP Period end run - purge only |

Controls access to the Purge only processing function in the WIP Period End program. |

| WIP Period end run - year end only |

Controls access to the Year end only function in the WIP Period End program. |

| WIP Period end run - year end and purge |

Controls access to the Year end and purge function in the WIP Period End program. |

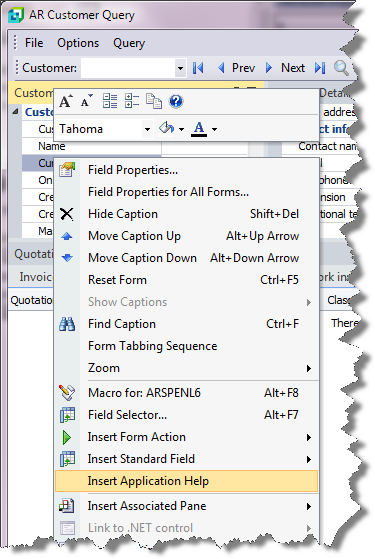

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.