You use this program to set a job to complete and distribute any outstanding work in progress amounts to the General Ledger. In addition, this program can also be used to set a job to incomplete.

- Toolbar and menu

- Preferences

- Job Entry Details

- GL Distribution Entry

- Posting Details

- List of Journals

- Journal Entries

- Outstanding WIP Values

- Notes and warnings

| Field | Description | ||||

|---|---|---|---|---|---|

| Options | |||||

| Preferences | Indicate the default settings you require for this program. | ||||

| Change Period | Use the Change Posting Period program to change the general ledger

period to which you want to post transaction entries. You can change this before you post your first transaction. To change the posting period once you have posted at least one transaction, you will need to exit the program and re-load it. |

||||

| Change Date | Change the date that must be used for the transaction. | ||||

| New | Clear all information currently displayed on the screen and indicate a job number to close. | ||||

| GL Distribution |

Distribute any outstanding work in progress values to the General Ledger module. You use this function to re-enable the GL Distribution Entry listview, if you selected the Save option before entering all transactions (i.e. before the undistributed value is zero). The values to distribute are calculated according to the Costing method (Inventory Setup) and the cost basis selected for the receipt of the job (see Job Receipts).

|

||||

| Post |

Post any outstanding amounts to General Ledger. All outstanding amounts must be fully distributed before you can select this option. All reserved stock against allocations is released when the job is set to complete. This applies when the Reserve stock for confirmed jobs option is enabled (Work in Progress Setup) and stock was reserved for the allocation. When a job for a notional part is closed:

|

||||

This screen is displayed when you select the Preferences function.

| Field | Description |

|---|---|

| Save Preference | Save your selections against your operator code. Your

selections remain in force until changed. If you do not select this option before closing the screen, then your preferences are applied for the current run of the program only. |

| Default ledger code | |

| Ledger code | Indicate the default General Ledger distribution account that must be used during the ledger distribution phase of the program. |

| Ledger description | The description defined against the General Ledger code you selected. |

| Field | Description |

|---|---|

| Job | Indicate the job you want to close. |

| Job description | The description defined against the job. |

| Stock code | The parent item being manufactured against the job. |

| Stock code description | The description of the parent item being manufactured against the job. |

| Rev/Rel | The revision/release of the parent stock item, where this item is ECC controlled. |

| Unit of measure | The unit of measure for the parent item. |

| WIP outstanding values | |

| WIP material value |

Indicate the outstanding material value that must be distributed for the job. This defaults to the outstanding work in progress material value for the job. This is calculated as: WIP Material value = Material costs to date - Material Issues from WIP where: Costs to date = Cost of material issued to the job and Issues from WIP = Cost of material distributed from WIP on receipt |

| WIP labor value |

Indicate the outstanding labor value that must be distributed for the job. This defaults to the outstanding work in progress labor value for the job. This is calculated as: WIP labor value = Labor cost to date - Labor Issues from WIP where: Costs to date = Cost of labor issued to the job and Issues from WIP = Cost of labor distributed from WIP on receipt |

| WIP total value | The work in progress value for the job. |

| Additional reference |

Enter an additional reference notation for the job receipt. The text you enter here is printed on the Distribution report and is displayed when you select the WIP Booked tab of the WIP Query program. |

| Job complete |

Set the job to complete or deselect this option to set the job to incomplete. This option is selected by default when you access the Job Closure program. When you set a job to complete:

You can deselect this option to set a previously completed job to incomplete. When you set a job to incomplete, the following apply:

Milestone operations are not set to complete when a job is set to complete. They are only set to complete when using the Labor Posting program to complete the operation. The reason is that a job can be reset to incomplete, but a milestone operation can not. When you close a job that is already completed, you are prompted to update the Job complete date with the transaction date if these dates differ. If you select Yes, then the Job complete date is changed to the Journal transaction date. |

| Dates | |

| Job delivery date | The date on which the job should be finished. |

| Job start date | The date on which the job must be/was started. |

| Job complete date | The date on which the job was completed. |

| Quantity | |

| Quantity to make | The quantity you selected to manufacture for this job. |

| Quantity manufactured | The quantity manufactured to date. |

| Quantity outstanding | The quantity of the finished item that is still outstanding for the job. |

| WIP issued values | |

| WIP material issued value | The current total value of materials issued to the job. |

| WIP labor issued value | The current total value of labor issued to the job. |

| WIP total issued value | The current total value of materials and labor issued to the job. |

This editable listview enables you to distribute any outstanding amounts for the job to ledger accounts of your choice.

As you add distribution lines to the listview, a running total is displayed at the bottom of the pane.

| Field | Description | ||||

|---|---|---|---|---|---|

| Save | Save the distribution entries.

|

||||

| Delete |

Remove the currently highlighted transaction from the entries listview. You can only select this option if an entry has already been added. |

||||

| Apply Undistributed | Assign the total outstanding amount to the specified ledger code. | ||||

| Ledger code |

Indicate the ledger code to which you want to distribute outstanding amounts for the job. If defined within the Preferences, the default G/L distribution account is displayed here automatically. This field is only validated if the Work in Progress module is integrated to the General Ledger in detail or summary (General Ledger Integration). |

||||

| Ledger description | The description defined against the ledger code you entered. | ||||

| Distributed amount | Indicate the amount you want to distribute to the specified ledger account. | ||||

| Total | This is displayed at the bottom of the pane and indicates the amount currently not distributed to a ledger account. You will not be able to post the job closure transactions until this value is zero. | ||||

| Field | Description |

|---|---|

| Posting month | The period into which the transactions will be posted.

You can change this before you post your first transaction. Once you have posted at least one transaction, this field is disabled. To change the posting month, you will need to exit the program and re-load it. |

| Posting year | The year into which the transactions will be posted. |

| Transaction Date | Indicate the date that must be used for the transaction. |

| Posting values | |

| Total value | The total material and labor value to be distributed to the job. |

| Distributed value | The total value you have currently distributed. |

| Undistributed value | The total value that must still be distributed. You will be unable to post the job closure transactions until this value is zero. |

The information in this pane is displayed when you post transactions. Only one journal is created for the run of the program, but a new line is created for each job to which you process transactions.

| Field | Description |

|---|---|

| Journal | Indicates the Work in Progress journal number created for the transaction. |

| Journal date | Indicates the date on which the Work in Progress journal was created for the transaction. |

| Operator | Indicates the code of the operator who created the journal. |

| Labor value | Indicates the total labor value for the journal. |

| Material value | Indicates the material value for the journal. |

This displays the journal lines for the journal displayed in the List of Journals pane.

| Field | Description |

|---|---|

| Line | Indicates the journal line number created by the transaction. |

| Job | Indicates the job against which the transaction was processed. |

| Stock code | Indicates the parent stock code for the job. |

| Transaction value | Indicates the total transaction value posted. |

The details in this pane are displayed for information purposes only.

| Field | Description |

|---|---|

| Month | Indicates the months for which the values are displayed. |

| Material value | Indicates the outstanding Work in Progress control material value for the job in the corresponding months. |

| Labor value | Indicates the outstanding Work in Progress control labor value for the job in the corresponding months. |

-

Completed jobs are only purged by the WIP Period End program if there are no outstanding values held against the job.

-

If the GL analysis required option is enabled for a ledger account used in this program (General Ledger Codes or GL Structure Definition) then the Capture GL Analysis Entries program is displayed when you post the transaction, so that you can enter the analysis details. For a sub module transaction, the sub module must also be linked to the General Ledger in Detail at company level (General Ledger Integration) or at ledger account code level (General Ledger Codes or GL Structure Definition). GL analysis entries cannot be entered from sub modules if the sub module is linked to the General Ledger in Summary at company level or at ledger account code level.

Note that the GL analysis required option is ignored for all GL codes which are defined in General Ledger Integration. This applies even when the GL code is manually entered in a posting program. Although GL integration programs may be entered manually, they may also be called automatically by other programs or may be automated, which means that they can never be stopped to allow GL analysis entries to be captured.

If the GL analysis code used does not exist in the GenAnalysisCat table, then a message to this effect is displayed and the program will not prompt for analysis again. The GL journal will be created but not posted until the GL code, GL analysis code and GL journal are corrected.

The Ask Me Later function is only available when the option: Force GL Analysis - GL journal posting is enabled for the sub-module (General Ledger Integration).

General Ledger analysis entries are always distributed in the local currency, regardless of the currency in which the original transaction is processed.

Electronic Signatures provide security access, transaction logging and event triggering. This enables you to increase control over your system changes.

Access to the following eSignature transactions within this program can be restricted at Operator, Group, Role or Company level. You configure this using the eSignature Setup program.

| eSignature Transaction | Description |

|---|---|

| WIP Job closure |

Controls access to the Post Transaction function in the Job Closure program. |

Password access to the following functions in this program may be defined in the Password Definition program. When defined, the password must be entered before you can access the function.

| Field | Description |

|---|---|

| WIP Completing a job if outstanding po's/materials/operations | This password restricts access to using the Job ReceiptsJob Closure or Part Billings program to set a job to Complete when there are outstanding materials or operations to be issued to the job, or outstanding purchase orders against the job. |

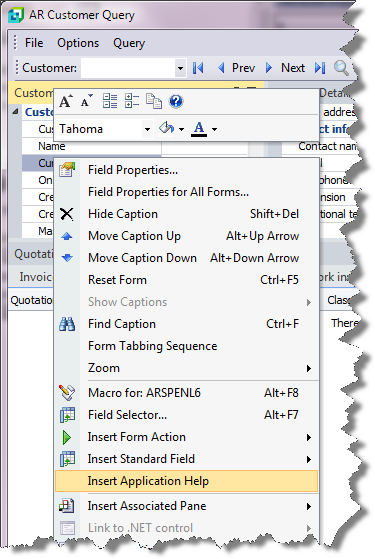

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.

![[Note]](images/note.png)