You use this program to capture and maintain a number of offers that can be presented to a customer for consideration.

When the customer accepts a quotation, you can use the Quotation Confirmation program to confirm this and convert the quotation into a sales order, a job, or a combination of both. If there is insufficient stock available, a purchase order or requisition can be created using the Quotation Purchasing Review program.

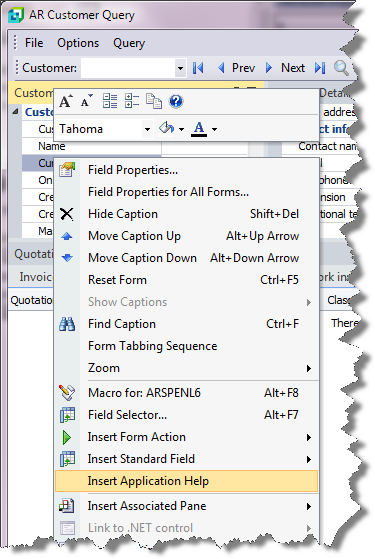

- Toolbar and menu

- Preferences

- Quotation Header

- Customer Details

- Quotation Offer Values

- Quotation Detail Lines

- Quotation Detail Values

- Quotation Lines

- End Quotation

- Status Codes

- Notes and warnings

| Field | Description |

|---|---|

| File | |

| New Quotation | Select this to create a new quotation. |

| Save Quotation |

Select this to end the quotation and save the information added or changed (see End Quotation). If the customer accepts a quotation, then it can be converted into a sales order, a job, or a combination of both. If there is insufficient stock available, then a purchase order or requisition can be created from the sales order or the job. If a custom form is defined for Quotations and at least one of the fields on the form is defined as mandatory, then you are prompted to enter the custom form details before you can save the quotation. |

| Cancel Quotation |

Select this to cancel the entire quotation and discard any entries made to the quotation you are currently processing or maintaining (see Cancel Quotation). If quotation versioning is required and you cancel a quotation, then all versions of that quotation are cancelled. |

| Functions | |

| Copy | Select this to create a new quotation based on the

details of an existing quotation. This option is only enabled when you select to create a new quotation (see Copy Quotation). This option is disabled after you enter or tab off the Quotation field. To copy a quotation, you must therefore enter the quotation number to copy and then immediately select the Copy option. When you copy quotations created from Product configurations, associated jobs and configuration libraries are not copied across. |

| Options | |

| Preferences | Select this to indicate the default options required for quotation entry (see Preferences). |

| Customer Defaults | Select this to set the customer defaults to use when creating a quotation with no customer (see Customer Default Preferences). |

| Quotation Details | Select this to indicate the default quotation

profit/markup percentage and descriptions for each of the

offers. This option is only available if the quotation you are maintaining is in a status of Preparation (see Quotation Details). |

| Order Header | Select this to use the SO Header Maintenance program to indicate the default sales order header information to use when converting quotations into sales orders. |

| Quotation |

Enter the quotation number to maintain. When adding a new quotation:

|

| Version | Displays the version number of the current

quotation. This only applies when the Quotation versioning required option is enabled in the Quotations Setup program. |

| New Quotation | Select this to add a new quotation. |

| Add Lines | Select this to add stocked, non-stocked, freight, miscellaneous and comment lines to the quotation. |

| Play | Select this to use the Multimedia program to view any multimedia objects assigned to the currently displayed quotation. |

| Hold |

Select this to place the quotation currently displayed on hold (see Place Quotation on Hold). You cannot confirm a quotation that is on hold. This does not update the quotation version number when using quotation versioning. |

| Save |

If quotation versioning is enabled and you have not made any changes to the current quotation, or you have only changed the custom forms on the header, then you are prompted to increase the version when selecting Save. |

| Select this to print the quotation. This only applies

when the Quotation status is 1

- Ready for printing. The quotation version is incremented if quotation versioning is enabled. Only the current version of the quotation can be printed when Quotation versioning required is enabled. |

|

| Make Current Version |

Select this to copy an existing version to the latest version. All versions of the quotation are retained. For example, if you are currently at version 6 of a quotation and you decide to make version 2 active (the current version) then version 2 is copied to version 7 and version 6 is marked as superseded. Versions 1-6 are still saved in the table. This is only enabled when the Quotation versioning required option is enabled (Quotations Setup). |

| Release Hold |

Select this to release the quotation from its on hold status. You are prompted to confirm the release of the on hold status. This only applies when the quotation is currently on hold. This does not update the quotation version number when using quotation versioning. |

This screen is displayed when you select the Cancel Quotation option from the File menu.

| Field | Description |

|---|---|

| Reason code | Enter the reason code for the

cancellation. Reason codes are maintained using the Quotations Browse on Reason Codes program. |

| Description | When you enter a reason code, the default description for the reason code is displayed, but can be changed. |

| OK |

Select this to accept the reason code and description and to return to the previous screen. When you cancel a quotation, all versions of that quotation are cancelled. |

| Cancel | Select this to return to the previous screen without cancelling the quotation. |

This screen is displayed when you select the Copy option from the Function menu. It enables you to create a new quotation based on the details of an existing quotation.

Changes to the new quotation, such as price or discount changes, must be done manually by editing the individual quotation lines.

![[Note]](images/note.png)

|

|

|

If the quotation from which you are copying has automatically generated non-stocked codes, then you have to generate new non-stocked codes, or exclude those lines from having the automatically generated codes. |

|

| Field | Description |

|---|---|

| Copy |

Copy the selected quotation. Quotation notes are copied to the new quotation. If custom form details attached to the original quotation are not copied to the new quotation. If mandatory fields exist on the custom form, then you are prompted to enter the custom form details for the new quotation. |

| Close | Return to the previous screen without copying the quotation. |

| Copy Quotation | |

| Copy from quotation | Indicate the existing quotation number to use to create a new quotation. |

| Copy from quotation version | Indicate the version number of the existing quotation number to use to create a new quotation. This only applies when the Quotation versioning required option is enabled (Quotations Setup). |

| Description | This indicates the description against the quotation you are copying from and is displayed for information purposes. |

| Copy to quotation |

Indicate the quotation number to create from the quotation selected in the previous field. If automatic quotation numbering is enabled in the Set Key Information program, then {Auto} is displayed in this field. This cannot be changed as the quotation number is automatically assigned when the quotation is saved. If manual quotation numbering is selected, then you must enter a quotation number. |

| Update dates to current dates |

Select this to set the quotation header dates for the new quotation to the current system date. If you do not select this option, then the quotation header dates on the new quotation are the same as the header dates on the quotation you are copying from. When you copy a confirmed or printed quotation, the confirmed and printed dates are not copied to the new quotation. |

This screen is displayed when you select the Hold option.

![[Note]](images/note.png)

|

|

|

You cannot confirm or print a quote that is on hold. |

|

You have to enter a reason for placing the quote on hold.

| Field | Description |

|---|---|

| Reason code |

Enter the reason code for placing the quotation on hold. Reason codes are maintained using the Quotations Browse on Reason Codes program. |

| Description | The description defined against the reason code is automatically displayed in this field, but can be changed. |

| OK | Select this to place the quotation on hold. |

| Cancel | Select this to return to the previous screen without placing the quotation on hold. |

Preferences can be defined for adding and maintaining quotations. The various preferences options that can be selected from the Options menu include:

- Preferences (see Preferences)

- Customer Default Preferences (see Customer Default Preferences)

- Quotation Details (see Quotation Details)

This screen is displayed when you select the Preferences option from the Options menu.

The preferences you set here determine the details displayed when maintaining a quotation.

When you add, change or delete stocked, non-stocked, miscellaneous or freight lines you can add custom form fields for those detail lines.

| Field | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Save Preferences | Save these preferences against your operator code and use them for future runs of the program until next you change them. | ||||||||||

| Details view options | The preferences set here determine the details displayed when maintaining a quotation. | ||||||||||

| Include comments | Select this to view comment lines when maintaining a quotation. | ||||||||||

| Include freight charges | Select this to view freight lines when maintaining a quotation. | ||||||||||

| Include miscellaneous charges | Select this to view miscellaneous charges when maintaining a quotation. | ||||||||||

| Default line type | |||||||||||

| Line type |

The option you select here determines which tab is displayed by default when you select to add a detail line to a quotation. You typically select the line type you are likely to add most often to a quotation.

|

||||||||||

| Options | |||||||||||

| Automatic quotation selection using prev/next | Select this to be able to select a quotation using the previous and next buttons. | ||||||||||

| Prompt default offer if non specified | Select this to be prompted to select a default offer if you enter several offers and do not specify a default. | ||||||||||

| Prompted mode for single level BOM | This option applies to Kit items. Select this if you want the program to wait for an operator response (accept, skip to next, end) for each optional component encountered when processing a kit item. Otherwise the operator is able to perform maintenance (accept, components, remove optional, change) only once all the components have been generated for the parent kit part. |

This screen is displayed when you select the Customer Defaults option from the Options menu.

The customer defaults which are set here will be used if no customer is entered for the quotation.

| Field | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Save Preferences | Save these preferences against your operator code and use them for future runs of the program until next you change them. | ||||||||||||

| Customer default preferences |

Indicate the code of the default branch to use for quotations. The branch is used to integrate sales and payments to the General Ledger module. |

||||||||||||

| Customer branch |

Indicate the code of the default branch to use for quotations. The branch is used to integrate sales and payments to the General Ledger module. |

||||||||||||

| Geographic area |

Indicate a default geographic area to be used for quotations. If you are using tax by geographic area (Company Tax Options Setup) then the tax code held against the geographic area can be used to override the tax codes normally used. |

||||||||||||

| Salesperson |

Indicate a default salesperson to be used for quotations. The code assigned here is used to calculate commissions if the commission is based on the salesperson, and not the price of the product being sold. |

||||||||||||

| Currency |

Enter the default currency to be used for quotations. Care must be taken in selecting this currency. You cannot enter a customer against a quotation after it has been created if the customer currency is different to that in which the quotation was created. |

||||||||||||

| Document format | Indicate the code of the document format to use to print quotation documents using the Quotation Batch Printing program. | ||||||||||||

| Invoice terms |

The entry made here is used to determine the default settlement terms required for a customer. The system uses the invoice terms to calculate discount amounts as well as discount dates and due dates of customer documents. |

||||||||||||

| Nationality | Indicate the default nationality code to display when

adding quotations. This field is mandatory when the EC Vat system is in use (Company Tax Options Setup). |

||||||||||||

| Discount calculations | |||||||||||||

| Order discount based on order value/qty | Select this to apply discounts to the total value or total quantity of a quotation. | ||||||||||||

| Invoice discount code |

Indicate the discount code to use when calculating the quotation discount. If no code is selected, quotation discounts are not calculated automatically. |

||||||||||||

| Line disc according to prod class sold |

Select this to be able to assign discount breaks to specific customer/product class combinations. All common product classes for an order are accumulated and the total of each product class is compared to the discount break tables and the discount applied to each line accordingly. If to recalculate these discount breaks when confirming the quotation, then you need to enable the Quotations Setup option Recalculate line discount breaks. This ensures that the correct discount is applied based on the lines you selected to confirm. |

||||||||||||

| Line discount code |

This indicates the automatic discount to be used when calculating the discount for each detail line. If no code is selected, automatic invoice discounts are not calculated. |

||||||||||||

| Contract pricing details | |||||||||||||

| Contract pricing | Select this to use contract pricing to determine quotation values. | ||||||||||||

| Buying group 1 - 5 | Indicate the default buying group to use to determine the contract price for a quotation. | ||||||||||||

| Automatic price code | Enter an automatic price code to use to calculate the price when simple pricing is used. | ||||||||||||

| Tax | |||||||||||||

| Tax exemption |

|

||||||||||||

| Canadian GST | This only applies if your nationality code is defined

as CAN (Company Maintenance) and you indicated

that Canadian GST is required

(Company Tax Options Setup).

|

||||||||||||

| Canadian GST shown by | This only applies if your nationality code is defined

as CAN, and you indicated that Canadian

GST is required.

|

||||||||||||

| Price category/code table |

If you are using extended pricing, you can enter up to 26 codes determining the price code applicable to a category of products being sold. The pricing category from the inventory file is used to locate a place in the price category/code table. Depending on whether the inventory pricing method is coded or discounted, the price code found in this table is used against the discount table to locate the required discount or to locate a price entry in the inventory file. |

||||||||||||

This screen is displayed when you select the Quotation Details option from the Options menu.

| Field | Description | ||||||

|---|---|---|---|---|---|---|---|

| Quotation details | |||||||

| Non-stocked profit | Indicate the default quotation profit required for

non-stocked items.

|

||||||

| Markup/Margin percentage |

Enter the profit markup/margin percentage to apply to the offer(s), depending on whether you selected to base the profit percentage on a markup or a margin. The markup percentage is calculated as: ((Selling price - Cost) / Cost) x 100. The margin percentage is calculated as: ((Selling price - Cost) / Selling price) x 100. |

||||||

| Offer descriptions | Enter your own description for each offer. |

| Field | Description | ||||||

|---|---|---|---|---|---|---|---|

| General information | |||||||

| Quotation | This indicates the quotation currently being displayed. | ||||||

| Version | This is the quotation version number. This applies when

the option Quotation versioning required

is enabled (Quotations Setup). When maintaining a previously saved quotation, you are prompted to increase the version number if the option Always prompt for version increases is enabled (Quotations Setup). When this option is not enabled the version is automatically increased and no prompt is displayed. See Quotation Version. |

||||||

| Description | Enter a description for the quotation. | ||||||

| Hierarchical |

Select this to link this quotation to a contract and/or to create hierarchical jobs from the quotation. Hierarchical jobs are used in the Projects and Contracts module, where the jobs typically consist of a number of hierarchical levels. This option cannot be selected for quotations that contain non-stocked lines which are not made in or subcontracted, stocked lines, or stocked lines linked to a product configuration which can be re-used (Product Configurator Header Maintenance). |

||||||

| Customer |

Enter the customer code for which to create the quotation. If the customer is on hold, then a warning message is displayed, but you can accept the message and continue. If you select to link the quotation to a contract, then the customer defined against the contract must be entered in this field.

|

||||||

| Customer name |

This indicates the name of the customer for whom the quotation is being prepared. If the customer is held on file then the name associated with that customer is displayed here by default. Although you can enter different customer name details, the entry reverts to the customer name configured against the customer. If you leave the Customer field blank then you can enter any text at the Customer name field. |

||||||

| Contract |

Enter a contract number if a valid contract exists with this customer. The contact number enables you to link multiple jobs to one contract. This field is used for Projects and Contracts. You use the Hierarchical contract field for hierarchical quotations. This field is disabled when you select the Hierarchical option. |

||||||

| Hierarchical contract | Enter an hierarchical contract number if a valid contract exists with this customer. You use the Browse on Contracts program to create and maintain hierarchical contract details. This field is only enabled when you select the Hierarchical option. Note that this field is not displayed by default. You need to add it to the form by right clicking within the Quotation Header form and selecting the Show Captions option. |

||||||

| Job classification |

This indicates the job classification assigned to the quotation. This defaults to the job classification held against the operator, if defined in the Operators program. The job classification entered here can be used as a selection criterion when printing a list of quotations. It can also be used when confirming the quotation and you select to create a job. At that point the program establishes the default job classification to use. The classification assigned to the non-stocked code takes precedence. If this is blank, then the classification entered against the quotation header is used. If this is blank, then the classification assigned to the operator is used.

|

||||||

| Probability |

Indicate the probability factor for the quotation. This is the likelihood of the client accepting the quotation. The probability is used as a selection criterion when performing an MRP Requirements Calculation. |

||||||

| Quotation status | This indicates the current status of the quotation, but

can be changed. You can also set the status of the quotation when you select the End Quotation option (see End Quotation). Refer to Status Codes for information on quotation status codes.

|

||||||

| Display lines that affect | Indicate the offer(s) for which to display quotation

lines in the Quotation Detail Lines listview. One of the following options can be selected:

|

||||||

| Non-stocked auto generation prefix |

If you select the Auto link in the Quotation Lines pane to auto generate non-stocked codes, then you define the prefix to use for the new non-stocked code in this field. The non-stocked code is created using this Prefix followed by the quotation line number. |

||||||

| Dates | |||||||

| Date of query | This defaults to the current system date when you add a new quotation. This can only be changed if the Quotations Setup option: Allow changes to date of query is enabled. | ||||||

| Expiry date |

This date is determined by the Date options defined for quotations (Quotations Setup). This date can only be changed if the Quotations Setup option: Allow changes to expiry date is enabled. You can enter zeros in this field to indicate that the quotation does not expire if the setup option: Allow zero expiry date is enabled. |

||||||

| Tender date | Enter the tender date if the quotation is being created for a tender. | ||||||

| Ship date | The ship date defaults to the current date, but can be

changed. This is the date on which the items can be shipped to the customer if the customer accepts the quotation. The ship date can be changed for each line on the quotation, depending on the item's availability. When you change this date, you are promoted to update the quotation detail lines with this new date. If you select "Yes", then the lines are updated only when you select the End Quotation function. |

||||||

| Follow-up-date | Enter any follow-up date you require for the quotation. You typically use this date to follow up on the quotation before it expires. Note that this field is not displayed by default. You need to add it to the form by right clicking within the Quotation Header form and selecting the Show Captions option. |

||||||

| Quotation notes | |||||||

| Notes | Select this to use the Admin Notepad Editor (Rich Text) program to add free

format notes to the quotation. These notes can be printed on the quotation document (see - Preferences - Notepad). When you copy the quotation, the notes are copied to the new quotation. When you create a purchase order from the quotation, you can optionally copy these notes to the purchase order (Quotation Purchasing Review). |

||||||

This is displayed when the Always prompt for version increases option is enabled in Quotations Setup.

It is displayed only once on the first change when maintaining a quotation.

If the first change is adding a kit type, then the prompt is displayed when you save the components. If the first change is adding a line, then the prompt is displayed when you save the line. In all other cases, the prompt is displayed as soon as the change is made.

| Field | Description |

|---|---|

| Do you want to increase the version number? | |

| Yes | Select this to increase the version number. |

| No | Select this to leave the version number as it is currently. |

The customer details entered here are printed in the heading section of the quotation.

If you create a quotation for someone who is not a customer, then the defaults configured in the Customer Default Preferences are used. You have to enter a valid customer before the quotation can be confirmed.

If you create a quotation for a customer, then the defaults configured against the customer are used, but can be changed.

Customer Details can only be maintained for quotations that are in a status of Preparation.

| Field | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Customer information | |||||||||

| Customer p/o | Enter the purchase order number received from your customer. | ||||||||

| Contact |

Enter a customer contact name and/or number. |

||||||||

| Telephone | Enter the customer's telephone number. | ||||||||

| Fax |

This defaults to the fax number defined against the Document transmission method for the customer. If this is not defined, then the fax number defaults to the number entered in the Fax field against the customer. When you fax quotations online, then the fax number entered here is presented as the default number. When you fax quotations in batch mode, then the fax number entered here is used. |

||||||||

|

Enter the customer's e-mail address. In most cases, when you e-mail quotations, the address entered here is presented as the default address. However, when you use the Quotation Batch Printing program and select to e-mail a quotation to a single customer, the e-mail address defined against the customer is presented as the default address. |

|||||||||

| Communication | This defaults to the Document

transmission method for quotations defined against

the customer, but can be changed here.

|

||||||||

| Salesperson | Indicate the salesperson for this quotation. | ||||||||

| Currency |

This indicates the currency to use for the quotation. The currency defaults to the currency defined against the customer. |

||||||||

| Document format | This indicates the document format to use to print the quotation using the Quotation Batch Printing program. | ||||||||

| Nationality |

Enter the nationality code of the customer. This is only applicable if EC VAT is installed. The nationality code influences how transactions are processed, including ensuring that the correct EC information is captured when raising a sales order for a customer in an EC Member State. |

||||||||

| Customer minimum order | This indicate the minimum order value for any single order for the customer (see Customers - Minimum order rules). | ||||||||

| Order discount | |||||||||

| Calculate order discount based on order value/quantity | Select this to apply discounts to the total value or total quantity of a quotation. | ||||||||

| Invoice discount code |

Select the discount code to be used when calculating the quotation discount. You can use the browse icon to view discount codes currently defined. If no code is selected, quotation discounts are not calculated automatically. This field is only enabled if you selected to calculate order discount based on order value/quantity. |

||||||||

| Order line discount | |||||||||

| Calculate based on product class sold |

Select this to be able to assign discount breaks to specific customer/product class combinations. All common product classes for an order are accumulated and the total of each product class is compared to the discount break tables and the discount applied to each line accordingly. The discount can only be calculated once you save the quotation. While creating a quotation, the program is unable to determine which offer will be confirmed, so the discount is calculated for each offer in its entirety. When a sales order is created the discounts are applied to the sales order. If, during confirmation you review the quotation, you are prompted to recalculate the discounts. If you select to do so, the system calculates the discount based on the offers you selected and those offers are refreshed with the customer/product class discounts. |

||||||||

| Line discount code | Select the automatic discount to be used when calculating the discount for each detail line. If no code is selected, automatic invoice discounts are not calculated. This is only enabled if you selected not to calculate discount based on product class sold. |

||||||||

| Contract pricing details | |||||||||

| Contract pricing | Select this to use contract pricing to determine quotation values. | ||||||||

| Buying group 1 - 5 | Indicate the default buying group to use to determine

the contract price for a quotation. This option is only enabled if you selected to use Contract pricing. |

||||||||

| Automatic price code | Enter an automatic price code to be used to calculate the price if simple pricing is being used. | ||||||||

| Price category/code table |

If you are using extended pricing, then you can enter up to 26 codes determining the price code applicable to a category of products being sold. The pricing category from the Inventory file is used to locate a place in the price category/code table. Depending on whether the Inventory pricing method is Coded or Discounted, the price code found in this table is used against the discount table to locate the required discount or to locate a price entry in the inventory file. |

The values in this pane are updated each time you add, change or cancel a quotation line.

The following information is included in this pane:

| Column | Description | ||||||

|---|---|---|---|---|---|---|---|

| Total for default offer |

|

||||||

| Total 1 - 5 |

For each offer, the following totals are displayed:

|

The lines added and saved against the quotation are displayed in this listview. Only the lines for the offer you selected at the Display lines that affect option in the Quotation Header pane are displayed. All quotation lines are only displayed if you selected A - All offers at the Display lines that affect option.

By typically right clicking on a line in the listview, or within the listview, you can select various options.

![[Note]](images/note.png)

|

|

|

The options available depend on whether you are entering a new quotation (i.e. no lines exist in the listview yet) or you are maintaining an existing quotation (i.e. you right click on an existing line in the listview). |

|

| Field | Description |

|---|---|

| Change Quote Header | Select this to use the SO Header Maintenance program to indicate the default order information to use when converting quotations into sales orders. |

| Add | Select this to add a stocked, non-stocked, freight or miscellaneous line to the quotation. |

| Insert Before Line | Select this to add a stocked, non-stocked, freight, miscellaneous or comment line quotation line before the currently highlighted line. |

| Add to End | Select this to add a stocked, non-stocked, freight, miscellaneous or comment line quotation line after the last existing line on the quotation. |

| Change | Select this to maintain the currently highlighted quotation line. |

| Cancel Line | Select this to cancel the currently highlighted

quotation line. When cancelling a quotation line linked to a job, the quotation link to the job is cleared. However, if you created a quotation line using the Product Configurator and you then maintain the line by re-using the configuration, then links to jobs for prior versions of the line are not cleared. These old links can be reinstated if the old version of the line is made current. |

| Product Configurator |

When maintaining a quotation, you can select this option to use the Configurator Wizard to modify the quotation line, by reusing the configuration used to create the quotation. The default offer is passed to the Product Configurator, but if this does not exist, then the first offer used is passed to the Product Configurator. The offer quantity needs to be supplied for this offer. Only one offer can be maintained so if there are any other offers, then these will pertain to the earlier quotation. This option is available when the line is linked to a configuration and the Allow in process configurations option is enabled against the configuration (Product Configurator Header Maintenance). When creating a quotation line from the Product Configurator, a configuration can only be re-used when the configuration is created from the Stocked tab. You can create stocked and non-stocked parent codes from this link, but jobs can only be created for stocked parent parts. You are prompted to load the configuration library associated with the line. If you select Yes, then the library is loaded and processing continues via the library (i.e. processing of selection criteria, options, components and operations are handled per the library). If you select No, then the configuration is loaded as per a new configuration. On return from the Product Configurator, the quotation line is updated with the changes made in the Configurator Wizard. Comment lines which were originally attached to the quotation are replaced with new comments added. If no new comments were added, then the original comments remain. Quotation versioning is applied as required (Quotations Setup). If the quotation line is linked to a job and changes are made to the structure, then the associated job is updated and the job costs are recalculated and updated. |

The following information is displayed in the listview for the lines of the quotation:

| Column | Description |

|---|---|

| Stock code | This indicates the code of the item being quoted. |

| Non-stocked code | This indicates the code of the non-stocked item for a non-stocked quotation line. This is blank for all other quotation line types. |

| Description | This indicates the description for the item being quoted. |

| Warehouse | This indicates the warehouse code from which the item was quoted. |

| Offers | This indicates the offer numbers used in the quotation. |

| Default offer | This indicates which offer is the default offer for the quotation. |

| Product code | This indicates the code of the Product configuration used to create the quotation line. This applies when the quotation line is linked to a configuration and the Allow in process configurations option is enabled against the configuration used (Product Configurator Header Maintenance). |

| Library code | This indicates the product configuration library code used to create the quotation line. This applies when the quotation line is linked to a configuration and the Allow in process configurations option is enabled against the configuration used (Product Configurator Header Maintenance). |

| Default quantity | This indicates the quantity for the default offer. |

| Default uom | This indicates the unit of measure for the default offer. |

| Default value | This indicates the value of the default offer. |

| Offers 1-5 | For each of the offers 1 - 5, the offer value, offer unit of measure and offer value is displayed. |

| Line | This indicates the line number of the line within the quotation. |

| Rev | This indicates the revision number of the item being quoted on, if the item is defined as ECC controlled. |

| Rel | This indicates the release of the item being quoted on, if the item is defined as ECC controlled. |

| Default u/price | This indicates the unit price for the default offer. |

| Default discount | This indicates the discount for the default offer. |

| Offers 1-5 | For each of the offers 1 - 5, the unit price and discount are displayed. |

The values displayed in this pane relate to the line currently highlighted in the Quotation Detail Lines listview.

![[Note]](images/note.png)

|

|

|

A single line can be attached to more than one offer. |

|

| Column | Description |

|---|---|

| Line Detail information | |

| Line type | This indicates whether the line is a stocked, non-stocked, freight, miscellaneous or comment line. |

| Stock code | This indicates the code of the item on the line. |

| Stock description | This indicates the description for the stock code. |

| Long description | This indicates the long description for the stock code. |

| Warehouse | This indicates the warehouse in which the stock item for which you are quoting is stocked. |

| Default entry | This indicates the default offer for the line. '00' indicates that a default offer is not specified for the line. |

| Product class | This indicates the product class for the item. |

The line details entered here are the details of the items which make up the quotation.

This pane is displayed when you select the Add Lines option or you select to add or change a line using your mouse button from the Quotation Detail Lines listview.

| Field | Description |

|---|---|

| Non-stocked | Select this to add a non-stocked line to the quotation (see Non-stocked). |

| Stocked | Select this to add a stocked line to the quotation (see Stocked). |

| Freight | Select this to add a freight charge line to the quotation (see Freight Line). |

| Misc Charge | Select this to add a miscellaneous charge line to the quotation (see Miscellaneous). |

| Comment | Select this to add a comment line to the quotation (see Comments). |

| Bitmaps | Select this to use the Multimedia program to associate a bitmap image with the quotation line. This option is only enabled for Stocked order lines. |

| Save | Select this to save the line. The details of the line you entered or updated are saved against the offer(s) you indicated. The Quotation Detail Lines listview is updated and the Quotation Lines listview is no longer displayed. When you save a line, margin checking is performed according to your selections in the Sales Orders Setup program. |

You use the Non-stocked tab to enter quotation lines for items that you do not stock in your Inventory Control system.

| Field | Description |

|---|---|

| Non-Stocked details | |

| Non-stocked code |

Enter the code of the non-stocked item to use for an offer. If you enter a code that does not exist, you are given the opportunity to add the code using the Non-stocked Codes program. Alternatively, you can select the Links > Auto option to automatically generate a new non-stocked item using the quotation number. This generated non-stocked code is specific to a quotation. If you enter the code for a bought-out item, which uses the Purchase price method and it has a status of under review, you can modify the price, notify the planner or cancel the line. The planner can use the Non-stocked Code Review program to maintain the purchase prices and make them available for use. If you enter the code for a made-in item and its estimate has a status of under development, then the following options are available: |

| Description | Enter a description for the non-stocked item. |

| Configurator | Select this to create a customized stock item using the Product Configurator. This creates a non-stocked parent item and attaches an Estimate Structure and Routing. |

| Product class | Indicate the product class to use for the item. |

| Order uom |

Enter the unit of measure applicable to the quotation line. This field is only enabled if you enabled the Request uom for order quantity setup option (Sales Orders Setup). |

| Default offer |

Indicate the offer to use as the default offer. The default offer which you specify for each quotation line can be used to automatically create sales orders/jobs/purchase orders or requisitions using the Quotation Confirmation program. |

| Ship date |

The ship date defaults to the current date, but can be changed. This is the date on which the items can be shipped to the customer. The ship date can be changed for each line on the quotation, depending on the item's availability. |

| Unit cost | This indicates the unit cost of the non-stocked item when it is a bought out item. |

| Tax information | |

| Taxable | You cannot access this field if you set the Tax

status to: Non-taxable on the

Tax Information tab of the

Order Header. Select this if the offer you are entering is taxable. If you select this option then you must enter the applicable tax code. |

| Tax code | This indicates the tax code to use for the line. This defaults to the tax code assigned to non-stocked items (Company Tax Options Setup) but can be changed. |

| GST taxable | This option is only displayed if your nationality code is set to CAN, and you are using the Canadian GST system. Select this option if the offer you are entering is subject to GST.If you select this option then you must enter the applicable tax code. |

| Links | |

| Auto |

Select this to create a new non-stocked item using the Non-stocked Codes program. The non-stocked code is automatically generated, using the Prefix entered in the Quotation Header pane together with the quotation line number. This non-stocked code is specific to a quotation. When creating a made-in non-stocked item, you can use the Estimates program to define the components and operations needed to make the item. |

| Purchase Prices | Select this to maintain purchase price of a bought-out item using the Browse on Non-stocked Purchase Prices program. |

| Estimate | Select this to use the Estimates program to define the components and operations needed to make a non-stocked item. |

| Perform Maintenance |

Select this to maintain the estimate using the Estimates program. You can only define a user defined hierarchy if the activity: P&C User defined hierarchies (Security Activities ), is allowed against your operator code. |

| Notify Planner | Select this to notify the planner so that the planner can use the Non-stocked Code Review program to maintain the estimate and make it available for use. |

| Continue | Select this to continue adding the line. |

| Cost/Lead Time Rollup |

Select this to use the Quotation Cost Implosion program to calculate the offer for a made-in item and its manufacturing lead time. This option is only enabled when you enter an offer for a non-stocked, made-in item and you enter and accept a quantity against the item's offer. The calculation is performed for the highlighted offer. |

| Line notes | Select this to use the Admin Notepad Editor (Rich Text) program to add free

format text attached to the quotation line. These notes are

copied when the quotation is copied to a new

quotation. Note that you need to save the line and then edit it to add the notes, because the line number, quotation and version are required to be able to save the notes. The notepad lines printed are output as comment lines and not as a separate XML element. |

| Offers | |

| Select | Indicate the offer(s) to which to attach the line details. |

| Dimensions |

Enter multiple 2 or 3 dimensional lines or frame lines. Once entered the resultant quantity is passed back to the quantity field and the multiple lines are converted into comments. |

| Quantity | Enter the quantity of the item for which to create an offer. |

| Pricing | This defaults to Markup% for non-stocked lines. |

| Markup % |

Select this to apply a markup or margin percentage to the offer. Enter the applicable percentage. This is enabled only when the option: Non-stocked profit change is enabled (Quotations Setup). |

| Fixed Price |

Select this to override the automatic price calculation and enter a price manually. You can only access the Fixed Price field if the option: Allow changes at quotation level is enabled. |

| Factor | Select this to enter a conversion factor if the price unit of measure you have entered is not held on file. |

| U/M | This indicates the unit of measure defined against the item. |

| Commission |

Enter the commission code which must be used to calculate the commission for the offer. Commission codes are maintained using the Browse on Commission Codes program. |

| Discount | This function enables you to enter up to three chained discount percentages or a discount value for the offer. |

| Discount Value | This indicates the discount value for the offer. |

| Routing | Indicate the route to be used for a made-in item. |

You use the Stocked tab to enter quotation lines for items that are stocked in your Inventory Control system.

| Field | Description |

|---|---|

| Stock details | |

| Warehouse | This indicates the warehouse in which the stock item

you are quoting for is stocked. You cannot change the warehouse when maintaining a parent/kit/component detail line. |

| Stock code |

Enter the code of the stock item for which you are creating an offer. By default, you enter the SYSPRO stock code in this field. You can, however, use the Field Selector to enter a stock code linked to a SYSPRO stock code in this field (see Stock Code Interchange). Items with a part category of Notional part (Stock Codes) cannot be selected. If the item is ECC controlled, you are prompted to enter the revision/rlease to use (see Revision/Release). A warning message is displayed if the stock code is on hold or on partial hold, but the line can still be maintained. An error message is displayed when adding a detail line for a Kit type S (Sub type) item which has no components. This only applies when the Single level Bill of Materials required option is enabled (Sales Orders Setup). |

| Description | This indicates the description defined against the stock item. |

| Revision/Release |

This is enabled for Engineering Change Control items only. It enables you to define the revision and release details for the ECC controlled item you are adding or maintaining. The wording displayed for this field defaults to Rev/Rel, but is replaced by whatever wording you have assigned to these user-defined fields (Bill of Materials Setup). |

| Configurator | Select this to create a customized stock item using the Product Configurator. |

| Default offer |

Indicate the offer to use as the default offer. The default offer which you specify for each quotation line can be used to automatically create sales orders/jobs/purchase orders or requisitions using the Quotation Confirmation program. |

| Ship date |

The ship date defaults to the current date, but can be changed. This is the date on which the items can be shipped to the customer. The ship date can be changed for each line on the quotation, depending on the item's availability. When adding a stock code with contract pricing, and the Use line date for contract pricing setup option is enabled (Sales Orders Setup) the detail line ship date will be used to get the contract price. |

| Unit cost | This indicates the unit cost of the item when it is a bought out item. |

| Tax information | |

| Taxable |

Select this if the offer you are entering is taxable. If you select this option then you must enter the applicable tax code. You cannot access this field if you set the Tax status to: Non-taxable on the Tax Information tab of the Order Header. |

| Tax code | Enter the tax code to use to calculate the tax for the line. The tax code displayed in the this field is the default tax code assigned to stocked items, but can be changed. |

| GST taxable | Select this if the offer you are entering is subject

to GST. If you select this option then you must enter the

applicable tax code. This option is only displayed if your nationality code is set to CAN, and you are using the Canadian GST system. |

| Extra Information | |

| Product class | This indicates the product class for the stocked item. |

| Unit mass | This indicates the unit mass defined against the stocked item. |

| Unit volume | This indicates the unit volume defined against the stocked item. |

| User defined | This indicates the user defined information defined against the stocked item. |

| Customer's stock code | This indicates the customer's stock code for the item. |

| Print component on order documents | Select this to print component details on order documents. This applies to kit type items. |

| Contract information | The following information is displayed if contract

pricing is defined for the customer for whom you are

creating the quotation:

|

| Queries |

Select these links to access additional information relevant to the stock code. |

| Line notes | Select this to use the Admin Notepad Editor (Rich Text) program to add free

format text attached to the quotation line. These notes are

copied when the quotation is copied to a new

quotation. Note that you need to save the line and then edit it to add the notes, because the line number, quotation and version are required to be able to save the notes. |

| Offers | |

| Select | Indicate the offer(s) to which to attach the line details. |

| Dimensions | Enter multiple 2 or 3 dimensional lines or frame lines. Once entered the resultant quantity is passed back to the quantity field and the multiple lines are converted into comments. |

| Quantity | Enter the quantity of items for which to create an offer. |

| U/M | This indicates the unit of measure defined against the item. |

| Price code override | Select this to override the price code for the item. You enter the required price code in the price code field. If defined, the password at the SO Changing prices field must be entered. |

| Price code |

The price code for the stock item defaults, but can be changed by selecting the Price code override option. For simple pricing, the automatic price code assigned to the customer is used to retrieve the corresponding price entry from the stock file. For extended pricing, the pricing category assigned to the stock item is used to determine which entry in the customer's price category/price code table must be used. The customer's entry is then used to locate the corresponding price code (if the stock item's pricing method is code) or the discount entry (if the stock item's pricing method is discounted). If defined, the password for SO Changing prices must be entered when changing the price code. |

| Last Price |

Select this to use one of the last two prices paid for the stock item by the customer. This only applies if you have selected the option: Customer/stock code cross-reference required. |

| Price override | Select this option to manually enter a price for the item. |

| Price | Enter a price for the offer if a manual pricing method is being used or to override the automatic price calculation and enter a price manually. |

| Factor | Select this to enter a conversion factor if the price unit of measure you entered is not held on file. |

| Price uom | Enter a pricing unit of measure for the offer if the pricing unit of measure differs from the order unit of measure. |

| Commission | Select the commission code which must be used to calculate the commission for the offer. |

| Discount | This function enables you to enter up to three

chained discount or markup percentages or a discount value

for the offer. (see Line Discount). |

| Discount value | This indicates the discount value for the

offer. The calculation of the line discount is affected by the pricing discount options set in Sales Orders Setup, especially the options: Line discount calculation and Basis for contract pricing. |

You use the Discount option to apply discount to a quotation line.

| Field | Description |

|---|---|

| Override calculated discount | Select this to apply the discount you enter manually using this Line Discount window and override the discount calculated by the discount breaks (if this is set on). |

| Discount % |

Select this to enter up to 3 chained discount percentages to apply to the quotation line. For example: Your line total is 100 and you define chained discount percentages of 10% and 5%. The calculation of discount is performed in the order listed:

|

| Discount percentage(s) | Enter up to 3 chained discount or surcharge percentages to apply to the quotation line. |

| Less | Select this to apply the percentages as a discount on the quotation line. |

| Plus | Select this to add the percentages to the quotation line as a surcharge or markup. |

| Total discount value | Select this to subtract a discount amount from the total shipped value of the stocked or non-stocked line. |

| Discount value | Indicate the total discount amount that must be deducted from the quotation line value. |

| Unit discount value |

Select this to subtract a discount calculated per unit of measure for the stocked or non-stocked items in the detail line. For example: If 3 units were entered, the unit discount value is multiplied by three and then subtracted from the total line value of the stocked or non-stocked line. |

| Discount value | Enter the discount value that applies to one unit of measure. This value is multiplied with the number of units in the Order quantity field or in the Ship quantity field, depending on your selection at the Unit discount calculated on option (Sales Orders Setup). |

| OK | Select this to apply the discount to the quotation line. |

| Cancel | Select this to return to the previous screen. |

The Field Selector at the Stock code field enables you to select which stock code linked to a SYSPRO stock code to enter in the Stock code field when adding a stocked quotation line.

| Field | Description | ||||

|---|---|---|---|---|---|

| Select Using Alternate key 1 | Select this to be able to enter the code defined in the Alternate key 1 field of the stock item in the Stock code field. | ||||

| Select Using Customer Interchange |

Select this to be able to enter the customer's stock code that is linked to a SYSPRO stock code in the Stock code field. After you enter and accept the customer's stock code, the equivalent SYSPRO stock code is entered in the Stock code field. Providing a link exists between the customer's stock code and the SYSPRO stock code, the customer's stock code is saved against the quotation line. This is regardless of whether you enter the customer's stock code or the SYSPRO stock code on the quotation line.

To enable the interchange of stock codes for the customer, you must select the option: Stock code interchange required against the customer. In addition, you must use the Customer Stock Codes program to define the link between the customer's stock code and the SYSPRO stock code. |

||||

| Select Using Supplier Interchange | Select this to be able to enter the supplier's

catalogue number that is linked to a SYSPRO stock code in

the Stock code field. After you enter

and accept the supplier's catalogue number, the equivalent

SYSPRO stock code is entered in the Stock code

field. To enable the interchange of supplier catalogue numbers and SYSPRO stock codes, you must enable the option: Supplier/stock code interchange system (Inventory Setup). In addition, a supplier code must be defined against the SYSPRO stock code. You use the Browse on Supplier Stock Code Cross Ref program to create links between the supplier's catalogue numbers and SYSPRO stock codes. Providing a link exists between the supplier's catalogue number and the SYSPRO stock code, the supplier's catalogue number is saved against quotation line. This is regardless of whether you enter the supplier's catalogue number or the SYSPRO stock code on the quotation line. The supplier's catalogue number can be printed on quotation documents. |

||||

| Select Using Matching Stock Codes | Select this to be able to enter a partial SYSPRO stock code in the Stock code field and view the stock codes matching your partial entry in a listview. This enables you to select the full stock code you require from the listview. | ||||

| Select Using Approved Manufacturers | Select this to be able to enter an approved

manufacturer's part number in the Stock

code field. You use the Browse on Approved Manufacturer Parts program to define details of approved manufacturers' part numbers and to link these part numbers to your SYSPRO stock codes. |

||||

| Remove This Selection | Select this to be able to enter only the full SYSPRO stock code in the Stock code field. | ||||

| Interchange popup toolbar | This is displayed when you select one of the stock

code interchange options. Depending on your selection, you will enter either the alternate key 1 code, the customer's stock code, the supplier's catalogue number, a partial SYSPRO stock code or an approved manufacturer's part number in the first field. |

||||

| Go | Select this arrow to use the stock code entered. | ||||

| Close | Select this to close the interchange popup toolbar for the current quotation line and return to the Stock code field. | ||||

| Remove | Select this to remove the current interchange selection, close the interchange popup toolbar and return to the Stock code field. The interchange popup toolbar is not automatically displayed again for the current quotation. | ||||

This screen is displayed when you add an ECC controlled item to the quotation. The fields enable you to indicate which revision/release of the item to use.

| Field | Description |

|---|---|

| Revision | Indicate the revision number of the item to use for the quotation. |

| Release | Indicate the release number of the item to use for the quotation. |

| Current when shipping | Select this to use the revision/release which is current for the item at the time the item is shipped. This applies if the quotation is accepted and converted into a sales order for shipping to the customer. |

| OK | Select this to accept your entries. |

| Cancel | Select this to ignore any entries you made and to return to the previous screen. |

You use the Freight tab to enter freight charges to a quotation.

| Field | Description |

|---|---|

| Freight details | |

| Product class | This displays the default product class assigned to a freight charge, which is _FRT and cannot be changed. |

| Default offer |

This indicates the offer which will be used as the default. The default offer which you specify for each quotation line can be used to automatically create sales orders/jobs/purchase orders or requisitions using the Quotation Confirmation program. |

| Tax information | You will be unable to access these fields if you set the Tax status to: Non-taxable on the Tax Information tab of the Order Header. |

| Taxable |

Select this if the freight charge is taxable. You will need to enter the appropriate tax code to calculate the taxable amount. |

| Tax code | Enter the tax code to use to calculate the tax for the line. The default tax code displayed is the default tax code assigned to freight charges (Company Tax Options Setup). |

| GST taxable | This option is only displayed if your nationality

code is set to CAN, and you are using the Canadian GST

system. Select this option if the freight charge you are entering is subject to GST. If you select this option then you must enter the applicable tax code. |

| Offers | |

| Select | Select the offer for which to enter line details. |

| Amount | Enter the amount to charge the customer. |

| Cost | Enter the cost amount to you of the freight. |

You use the Miscellaneous tab to assign miscellaneous charges, such as handling fees, to a quotation.

| Field | Description |

|---|---|

| Miscellaneous details | |

| Description |

Enter a description of the miscellaneous fee. You can use the browse button to select a sales order standard comment. |

| Product class | The default product class for miscellaneous charges is _OTH, but can be changed. |

| Default offer |

This indicates the offer which will be used as the default. The default offer which you specify for each quotation line can be used to automatically create sales orders/jobs/purchase orders or requisitions using the Quotation Confirmation program. |

| Tax information | You cannot access these fields if you set the Tax status to: Non-taxable on the Tax Information tab of the Order Header. |

| Taxable |

Select this if the miscellaneous charge is taxable. You need to enter the appropriate tax code to calculate the taxable amount. |

| Tax code | Enter the tax code to use to calculate the tax for the line. The default tax code displayed is the default tax code assigned to miscellaneous charges (Company Tax Options Setup). |

| GST taxable | This option is only displayed if your nationality

code is set to CAN, and you are using the Canadian GST

system. Select this option if the offer you are entering is subject to GST. If you select this option then you must enter the applicable tax code. |

| Offers | |

| Select | Select the offer for which to enter line details. |

| Amount | Enter the amount which to charge the customer. |

| Cost | Enter the cost amount to you of the charge. |

You use the Comment function to enter comments against the quotation lines.

When you create a job from a quotation, comment lines attached to a non-stocked item are attached to the job as job narrations if:

- you selected to print the comment on the invoice

- the comment applies to the offer selected for the line.

The following types of comments can be added:

| Field | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Free Format Comments |

Select this option to manually enter comments for a quotation line using the text editor. Free-format comments which are attached to a made-in item are automatically copied to the job notes if you create a job. |

||||||||

| Standard Comments |

Select this to enter a standard comment (s). Standard comments are maintained using the SO Standard Comments program.

|

||||||||

| Stock S/Order Text |

Select this to attach sales order text which is defined against a stock code to the quotation. Stock comments (sales order and dangerous goods) can only be inserted if the previous line is for a stocked item. Stock sales order text can only be inserted if the text has already been assigned to the stock item. Sales order additional text is assigned to a stock item using the Notes option of the Inventory Query program. |

||||||||

| Stock D/Goods Text |

Select this to attach dangerous goods text which is defined against a stock code to the quotation. Stock comments (sales order and dangerous goods) can only be inserted if the previous line is for a stocked item. Stock dangerous goods text can only be inserted if they have already been assigned to the stock item. This text is added and maintained using the Notes option of the Inventory Query program. |

Once you have selected or inserted a comment, you can indicate the documents on which the comment must be printed, as well as the offer to which the comment applies and attach it to a specific line.

| Field | Description |

|---|---|

| Save | Save the comment against the applicable line. |

| Cancel | When you select this option you are prompted to confirm that you want to discard the comment lines. |

| Print comment on | |

| Print comment on quotation | Select this to print the comment on the quotation. |

| Print comment on delivery note | Select this to print the comment on the delivery note. |

| Print comment on invoice | Select this to print the comment on the invoice. |

| Comment options | |

| Attach comment to a previous line | Enable this to indicate the quotation line to which to attach the comment. |

| Previous lines | The lines to which the comment can be attached are displayed. If a line is not displayed, then the comment cannot be attached to that line. Select the line to which to attach the comment for printing. If, for example, you have 6 lines where the sixth line is a comment attached to line 3, then the comment is printed if you print line 3. It is also printed if you print lines 4 or 5 since the comment is effectively linked to all lines between the line to which it is attached and the comment line itself. In this example, the comment is not printed if you print only lines 1 or 2. If you cancel a line to which a comment is attached, then the comment line is cancelled only if it is directly below the cancelled order line. If the comment line is attached to the line, but is placed after another line, then it is not cancelled. For example, you have the following: Quotation line 1 Comment 1 attached to Quotation line 1 Quotation line 2 Comment 2 attached to Quotation line 1 You now cancel Quotation line 1. Comment 1 is cancelled, but Comment 2 remains, since Comment 2 is linked to all quotation lines between the line to which it is attached and the comment line itself. Therefore, it is important to position comment lines correctly within a quotation. Attaching a comment line to a line does not affect where the comment is actually printed on the document. If you require a comment to be printed with a specific order line, then you must insert the comment at the required position (i.e. after the order line to which you want it attached). Alternatively, use one of the specific comment types that can be associated with a stock item. |

| Offer to which comment applies |

Select the specific offers against which the comments must be attached. The offers can either be individually selected or deselected, or the Select/deselect all option can be used to apply to all offers. |

This screen is displayed when you add a kit type item to a quotation and the option: Single level Bill of Materials required (Sales Orders Setup) is selected.

The components of a kit are configured using the Structures and Routings program. At the time of adding a component to a kit type parent, you can indicate whether the component is optional or mandatory, and whether to print the component on sales order documents.

If you enabled the preference: Prompted mode for Single Level BOM (Preferences) then the program displays this screen for each optional component line that it encounters. You indicate whether to accept the line, skip the line or end allocations.

The type of kit configured against the parent part (Stock Codes) determines the cost, price and quantity applicable to the line (see Toolbar and menu).

| Field | Description |

|---|---|

| Accept Components | Select this to accept the components and offer quantities associated with the parent item. |

| Remove Optional | Select this to exclude the currently highlighted

optional component from the kit. Optional components are denoted by the word Yes in the Optional column of the Materials listview. |

| Change | Select this to maintain the component currently highlighted in the Materials listview. |

| Cancel | Select this to exclude all the components from the kit. |

| Details | |

| Parent | This indicates the parent part of the kit. |

| Description | This indicates the description for the parent part. |

| Warehouse | This indicates the warehouse in which the item is located. |

| Revision | This indicates the revision of an ECC-controlled item. |

| Release | This indicates the release of an ECC-controlled item. |

| Offer | This indicates the offer against which the parent

item exists. If the parent item is quoted against more than one offer, then you can select the offer against which to accept, cancel or change the components. |

| Offer quantity | This indicates the offer quantity of the parent item for the selected offer. |

| Offer uom | This indicates the unit of measure for the offer quantity of the selected offer. |

| Stocking quantity | This indicates the quantity in terms of the stocking quantity of the parent item. |

| Stocking uom | This indicates the stocking unit of measure of the parent item. |

This listview displays details of the components currently attached to the parent item.

| Column | Description |

|---|---|

| Stock code | This indicates the code of the component item |

| Description | This indicates the description of the component item. |

| Offer quantity |

This indicates the offer quantity of the component item. This quantity is established based on the 'quantity per' relationship between the parent and component. |

| Offer u/m | This indicates the offer unit of measure of the component item. |

| Price | This indicates the price of the component item. |

| Price u/m | This indicates the price unit of measure of the component item. |

| Optional | This indicates whether or not the component is optional. A Yes in this column indicates that the component is optional. |

This pane is displayed when you select the Change option.

![[Note]](images/note.png)

|

|

|

You can only change the order quantity of optional components if you have enabled the option: Allow qty changes to optional components. If you change the quantity of an optional component, it is flagged as no longer being part of the kit and subsequent changes to the parent order quantity are not applied to that optional component. |

|

| Field | Description |

|---|---|

| Ignore Component | Select this to exclude the component currently highlighted from the bill of materials. |

| Ignore Remaining Components | Select this to exclude the component currently highlighted and all further optional components from the bill of materials. |

| Accept Remaining Components | Select this to include the component currently highlighted and all remaining optional components in the bill of materials. |

| Accept Line | Select this to accept the changes you made to the line currently highlighted in the Kit Component Offer Entry pane. When you select to accept the component, it is included according to any changes you made. |

| Cancel | Select this to cancel all component lines attached to the parent part. |

| Kit Component | Changes can be made in this pane for both optional and mandatory components. |

| Stock code | This indicates the code of the component you are currently maintaining. |

| Description | This indicates the description of the component you are currently maintaining. |

| Product class | This indicates the product class for the component. |

| Print components on order document |

Indicate whether or not to print the kit component details on the order document. |

| Kit Component Offer Entry | Changes in this pane can only be made for optional components. |

| Select | This indicates the offers against which the parent

item (to which the component belongs) are selected against

the quotation. This is displayed for information purposes only. To deselect a component from an offer, you need to deselect the parent item from the offer on the main Quotations screen. |

| Quantity | This indicates the quantity of the optional component according to the bill, but can be changed. |

| U/M | This indicates the unit of measure of the optional component. |

| Price code override | Select this to override the price code for the item. You enter the required price code in the Price code field. |

| Price code | The price code for the component defaults, but can be changed by selecting the Price code override option. |

| Last price |

Select this to use one of the last two prices paid for the stock item by the customer. This function is only available only if you have selected the option: Customer/stock code cross-reference required. |

| Price override | Select this to manually enter a price for the component |

| Price | Enter a price for the component if a manual pricing method is being used or to override the automatic price calculation and enter a price manually. |

| Factor | Select this to enter a conversion factor if the price unit of measure you have entered is not held on file. |

| Price u/m | Enter a pricing unit of measure for the component if the pricing u/m differs from the order u/m. |

| Commission | Select the commission code which must be used to calculate the commission for the component. |

| Discount | Enter up to three chained discount percentages or a discount value for the component. |

| Discount value | This indicates the discount value for the component. |

This screen is displayed when you select the End Quotation option or you select the Print option from the Function menu.

| Field | Description |

|---|---|

| Offers to print | Indicate which offers from the quotation must be printed. |

| Offer | This displays the offer number. |

| Previously printed | This indicates whether or not the related offer has already been printed. |

| This displays whether or not the related offer is selected for printing. | |

| Deselect Offer | Select this to exclude the highlighted offer from being printed on the quotation. |

| Select All | Select this to include all offers for printing on the quotation. |

| Deselect All | Select this to exclude all offers from being printed on the quotation. |

| Reprint | Select this to reprint a quotation which was previously printed. |

| Last print date | This indicates the last date on which the quotation was printed. |

| Status | Refer to Status Codes for information on quotation status codes. |

| Preparation | Select this if the quotation is not complete. i.e. you need to add further details before finalizing and printing the quote. |

| Ready for printing | Select this if the quotation is complete and you want

to be able to print it. You cannot maintain a quotation which is in this status. |

| Document format |

Indicate the quotation document format to use to print the quotation. Quotation document formats are maintained using the Quotation Document Format program. |

| Number of offers format can print | This indicates the number of offers that can be printed using the document format you selected. |

| Define Format | Select this to define a document format for quotations using the Quotation Document Format program. |

| Fax details |

Select this to fax the quotation to your customer. The Fax Details function is only available if the Office Automation & Messaging module is installed and against the operator you selected the option: Fax/mail integration required. |

| Fax number |

This indicates the fax number to be used for faxing the quotation. This field defaults to the fax number defined against the quotation, but can be changed. |

| Print document if faxing | Select this to both print and fax the quotation. |

| Preview |

Select this to preview the quotation before printing it. |

|

Select this to e-mail the quotation to a customer. This is only available if you selected a format that prints using MS Word. The e-mail address defined against the quotation is presented as the default address. |

|

|

Select this to print/fax/email the quotation according to the selections you made. You can only print a quote if it is in a status of Ready for printing. When the quote is printed, the customer details are printed in the heading section and the line details are printed in their respective sections (e.g. Freight charges are printed in the freight charge section). |

|

| Continue Quote | Select this to return to the previous screen without printing, faxing or emailing the quotation. |

| End Quote | Select this to save any information entered and to end

the current quotation. If you entered a customer code against the quotation and a Minimum order value is defined for that customer, then a warning message is displayed if the quotation value is less than the Minimum order value. Refer to Customers - General Details - Minimum order rules for additional details. |

The following table describes the possible status codes that can be assigned to a quotation:

| Status code | Description |

|---|---|

| 0 - In progress | The quotation is currently being maintained by an operator or has been left in a status of Preparation. You can only maintain a quotation that is in a status of Preparation. |

| 1 - Ready for printing | The quotation can be printed. The quotation was set to Ready for printing as it is complete and can therefore be printed. |

| 2 - Printed | The quotation was printed. The only functions that can be performed on a quotation that is printed are: Change Status, Print, Hold and Cancel Quote. |

| 4 - Confirmed | The quotation was accepted by the customer and the Quotation Confirmation program was used to confirm the quotation. No changes can be made to a quotation that is in a status of Confirmed. |

| H - Hold | The quotation is currently on hold (see Place Quotation on Hold). |

| R - Rejected | The quotation was rejected by the customer and the Quotation Confirmation program was used to reject the quotation. Rejected quotations can be removed from the system using the Quotation Purge program. |

| \ - Cancelled | The quotation was cancelled (see Cancel Quotation). |

-

Quotations adhere to the pricing discount options set in Sales Orders Setup.

-