Inspection Engine

The configurable Inspection Engine feature assists you in creating an inspection system that adheres to the standards laid out by the International Organization of Standardization (ISO). It consists of a test engine and a dashboard that give you the opportunity to greatly improve internal controls over the manufacturing process and the quality inspection procedure of work in progress (WIP) and purchase order receipts.

Exploring

-

set own quality control standards

-

less variability within the product

-

reduced costs and wastage (less rework and scrap)

-

improved customer satisfaction (less defects and improved consistency)

The test engine is used to design inspection tests with acceptance quality levels, to capture inspection data and ultimately pass or fail the inspection. The inspection data helps businesses identify potential risks in the product, set tolerances against these risks, and ultimately accept or reject a product batch based on given criteria.

The programs related to this feature are accessed from the Program List of the SYSPRO menu:

- Program List > Quality Management

The acceptance quality limit is the level of defect that the business can accept in its product.

AQL sampling helps a business determine whether to accept or reject an order based on the number of defects found in the sample size. Every business needs to decide what the critical, major and minor defects are on its components, and what level of defects it can accept in its processes.

You can specify the accept / reject quantity for critical, major and minor defects within the Acceptance Quality Limit program.

The inspection test, also called inspection level test, is the test for the actual inspection of an individual item. Inspection tests are assigned to the sample test, which includes all inspection tests of the item. Once all individual inspection tests are done, the sample test is complete.

The test data, status and results of the individual inspection level tests are saved within the SqmIndTest table.

This encompasses the entire inspection that is performed on a purchase order or job that is received into inspection.

The inspection data, status and the results are saved within the SqmInspect table.

The sample test consist of one or more inspection tests, depending on the number of items that will be inspected, i.e. depending on the size of the sample taken from the entire batch that is received into inspection. A sample test is created for each item that is inspected and actual inspection tests of individual items are assigned to the sample test.

The test data, status and results are saved within the SqmTestStatus table.

Traceability refers to the ability of an organization to verify the history, location, or application of an item based on documented identification records.

Traceability is required in certain industries for a number of reasons:

-

Stock control

-

Asset control

-

Order tracking

-

Food Recall (e.g. being able to trace and account for every unsafe food item suspected of contamination; ranging from items still in the warehouse to those dispatched to customers).

WIP is an abbreviation used for work in process, work in progress, goods in process, or in-process inventory which are a company's partially finished goods waiting for completion and eventual sale. These items are either just being fabricated or waiting for further processing in a queue or buffer storage.

Starting

To use this feature, the following setup option(s) must be enabled/defined:

Program List > Inventory > Setup - Tracking pane:

-

Quality management

-

QM inspection required

-

-

Lot traceability control

-

Lot traceability

This must be defined as Inspection required.

-

Traceable

This must be defined as With inspection.

-

Allow issues from multiple lots

-

To use this feature, the following eSignatures must be defined accordingly in the Electronic Signature Configuration Setup program (as this allows for the various functions in the related programs):

-

QMS Acceptance Quality Limit Add

-

QMS Acceptance Quality Limit Change

-

QMS Acceptance Quality Limit Delete

-

QMS Add Document

-

QMS Add inspection Level

-

QMS Add Quality Management Test

-

QMS Assign Expected End Date

-

QMS Assign Inspector

-

QMS Assign Serial

-

QMS Change inspection level

-

QMS Change Quality Management Test

-

QMS Correct Test

-

QMS Delete inspection level

-

QMS Delete Quality Management Test

-

QMS Perform inspection

-

QMS Place on Hold

-

QMS Reason Code Add

-

QMS Reason Code Change

-

QMS Reason Code Delete

-

QMS View Quantities

-

QMS View Status

This only applies if the Secure by default option of your Global Configuration in the Electronic Signature Configuration Setup program is enabled prior to your updating to SYSPRO 8 2021 R2.

To use this feature, the following module(s) must be installed according to the terms of your software license agreement:

-

Quality Management

You can secure this feature by implementing a range of controls against the affected programs. Although not all these controls are applicable to each feature, they include the following:

- You restrict operator access to activities within a program using the Operator Maintenance program.

- You can restrict operator access to the fields within a program (configured using the Operator Maintenance program).

- You can restrict operator access to functions within a program using passwords (configured using the Password Definition program). When defined, the password must be entered before you can access the function.

- You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program). Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

- You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

- You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

-

Currently you can't define custom inspection levels. The available inspection levels are predefined and saved in the SqmInspectLvl table.

You will be able to define your own inspection levels in a following release of the software.

Solving

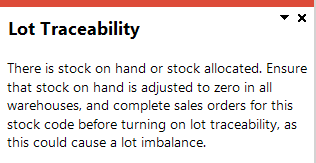

This message is displayed when you try to enable the QM inspection required option within the Stock Code Maintenance program and open Purchase Orders or Work in Progress transactions are linked to the stock code.

You can't enable inspections against a stock code if it forms part of any existing Purchase Orders or Work in Progress transactions.

You can either receive all outstanding work in progress and purchase orders and then enable the QM inspection required or possibly create a new stock code to be used for inspections in the Quality Management module.

The Inspection Engine that is used by the Quality Management module is enabled against the stock code.

-

Access the Stock Code Maintenance program.

-

At the Tracking pane enable the QM inspection required option.

This option is only available if the Lot traceability option is defined as Inspection required.

Once that is defined, the Traceable option will be updated to With inspection and the Allow issues from multiple lots will be enabled.

-

Save your changes.

You won't be able to save your changes if there is stock on hand for the selected stock code or if the stock code was allocated to a sales order that has not been completed.

The Inspection Engine uses the GRN (goods received number) or WIP inspection reference number as the inspection number.

If the Inspection Engine is used, the value at the Type key field in the SqmInspect table will consist of the GRN number, lot number (if applicable) and a P for purchase order inspections or the WIP reference number, lot number (if applicable) and a W for WIP inspections.

-

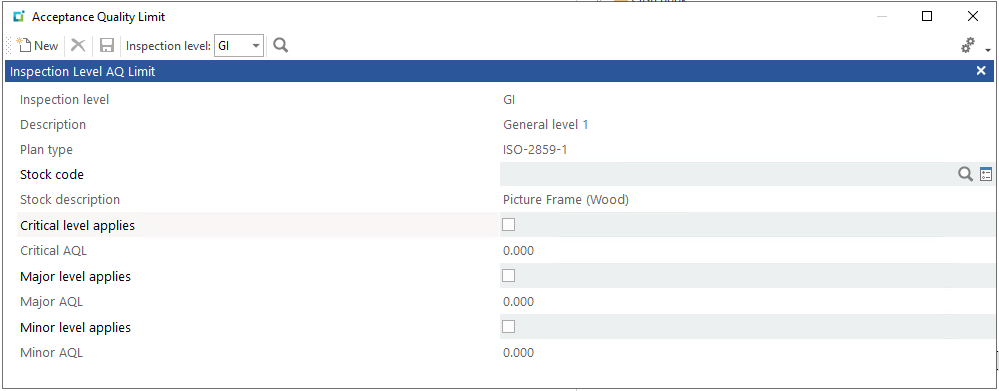

Access the Acceptance Quality Limit program.

-

Select the inspection level and plan type.

-

Select the stock code for which you want to create the inspection test(s).

-

Select the AQL level you want to apply to the inspection, e.g. critical, major or minor and enter the relevant values.

Currently you can't define custom inspection levels. The available inspection levels are predefined and saved in the SqmInspectLvl table.

You will be able to define your own inspection levels in a following release of the software.

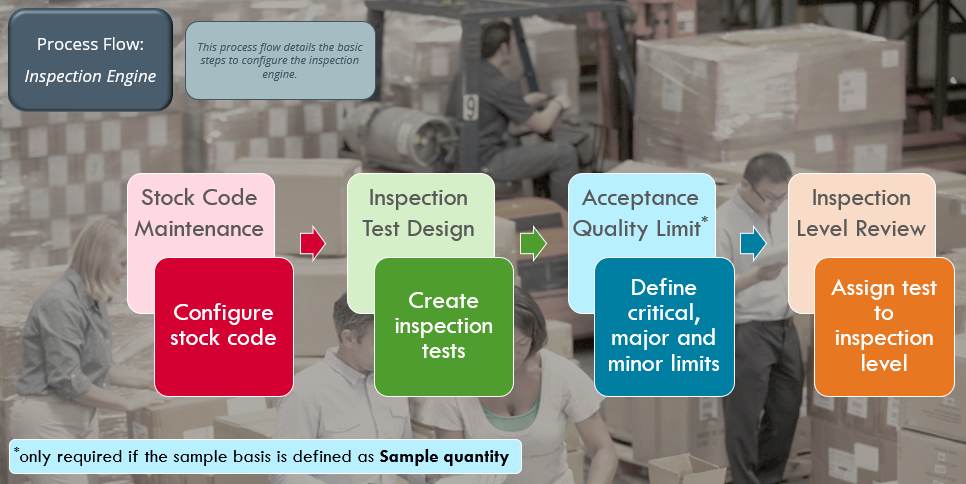

Using

-

Ensure that you have configured the relevant Electronic Signatures, as these are denied by default if the Secure by default option is enabled (Global configuration tab within the Electronic Signature Configuration Setup program).

-

Enable the QM inspection required option within the Stock Code Maintenance program.

The Lot traceability option will automatically be defined as Inspection required and the Traceable option as With inspection.

-

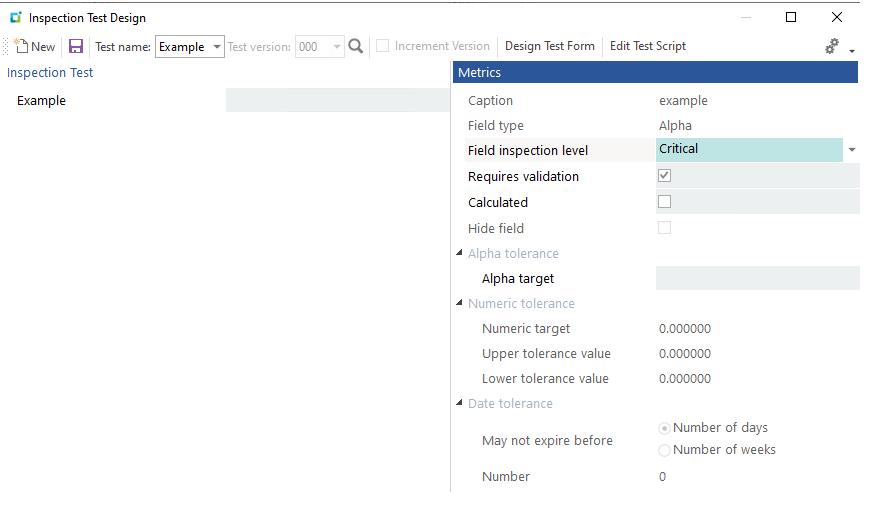

Design and create the inspection tests using the Inspection Test Design program.

-

Configure the AQL levels using the Acceptance Quality Limit program.

This step is only necessary if the Sample basis field of the inspection level is defined as Sample quantity.

You can define the sample basis at the Inspection Levels pane of the Inspection Level Review program.

-

Assign the inspection tests that should be executed per inspection level, i.e. the warehouse, stock code, customer or supplier.

Once added, the test is displayed at the Inspection Level Tests pane.

-

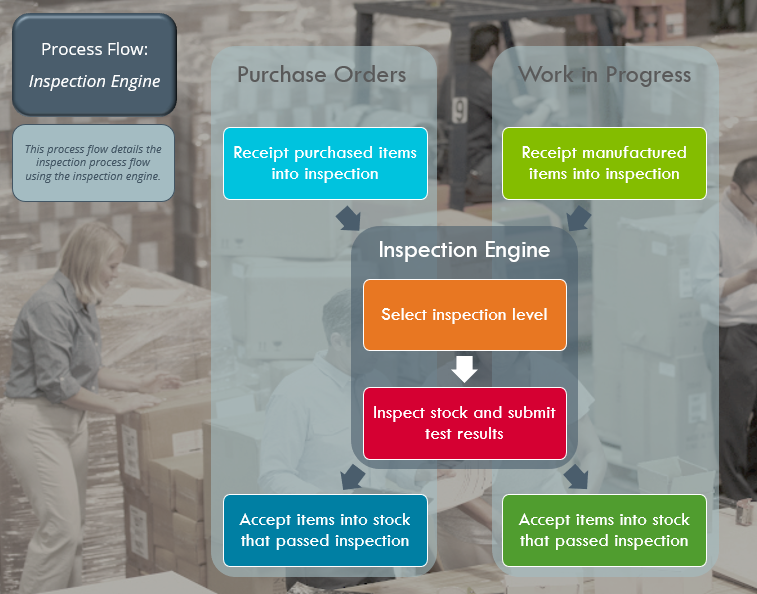

Depending whether you are inspecting purchased or manufactured items, receipt items into inspection and count the received quantities using the Purchase Order Receipts or WIP Inspection Maintenance program.

-

Select the inspection level using the Inspection Level Select program.

This program will only be displayed if the Sample basis field is defined as Sample quantity within the Inspection Level Review program.

-

Once the inspection level is selected, the following fields within the Purchase Order Receipts or WIP Inspection Maintenance program are updated:

-

The QM inspection status reflects Y - In progress, as the items have been counted.

-

The number of items that must be inspected is reflected at the Quantity in quarantine field.

-

-

Inspect the items and submit the results of the sample tests using the Inspection Test Queue program.

Once all the quarantined items are inspected and the test results submitted, the Inspection complete field displays Yes and the Inspection status is updated to Y - Passed inspection or N - Failed inspection.

-

Accept items into stock (or scrap, send for rework, reject, or QM return items) using the the Purchase Order Receipts or WIP Inspection Maintenance programs.

The QMS inspection status reflects C - Complete.

The following are possible status codes for a QM inspection used within the Quality Management:

| Status | Description |

|---|---|

|

R - Not started |

When a job is moved into inspection, the status of the QMS inspection is displayed as R - Not started as the count transaction must first be performed. |

|

Y - In progress |

This status is applied once the count transaction has been completed. |

|

C - Complete |

This status is displayed once all the sample tests and the QMS inspection have been completed. |

|

N - Not required |

This status code is displayed when a stock code is selected that requires inspection, and the QM inspection required option at the Tracking pane within the Stock Code Maintenance program is not enabled (i.e. the inspection will not be done using the Quality Management module). |

|

{blank} - Not required |

This status code is displayed when the Quality Management module is not installed. |

For purchase order inspections, the inspection statuses are saved within the InvInspect table and displayed at the Inspection status field of the Purchase Order Inspection program.

For Work in Progress inspections, the inspection statuses are saved within the WipInspect table and displayed at the QMS inspection status field of the WIP Inspection program.

The following are possible status codes for a Quality Management inspection test:

| Status | Description |

|---|---|

|

{blank} - In progress |

This status is displayed while the inspection is still taking place. When an inspection is placed on hold using the Inspection Test Queue program, the Inspection status is displayed as {blank} - In progress and the Inspection on Hold field reflects Yes. If the stock code (inspected during the Quality Management inspection) is placed on hold, the Inspection status is displayed as {blank} - In progress and the Stock code on Hold field reflects the stock code status, i.e. Full hold. |

|

N - Failed inspection |

This status is displayed when the inspection has been completed, but the inspection criteria weren't met and the QMS inspection failed. |

|

Y - Passed inspection |

This status is displayed when the inspection has been completed and approved. |

The inspection test statuses are saved within the SqmInspect table and the status is displayed at the Inspection status field and the Result column within the Inspection Test Queue program.

The following are possible status codes for a sample inspection test used within the Quality Management:

| Status | Description |

|---|---|

|

N - Not started |

This status is displayed when none of the individual tests assigned to the sample test have been started. The Result column in the listview reflects the status of the inspection test as {blank} - In progress. |

|

I - In progress |

This status is displayed once one of the individual tests assigned to the sample test have been started. The Result column in the listview reflects the status of the inspection test as {blank} - In progress. |

|

F - Complete / Failed |

This status is displayed once all individual tests assigned to the sample test have been completed. If the sample test failed the inspection, then the Result column in the listview reflects the status of the inspection test as N - Failed inspection. |

|

P - Complete / Passed |

This status is displayed once all individual tests assigned to the sample test have been completed. If the sample test passed the inspection, then the Result column in the listview reflects the status of the inspection test as Y - Passed inspection. |

The inspection sample test statuses are saved within the SqmTestStatus table and displayed at the Status field within the Inspection Test Queue program.

The individual inspection level test statuses are saved within the SqmIndTest table and the status is displayed at the Result column within the Inspection Test Queue program.

The following indicates areas in the product that may be affected by implementing this feature:

Program List > Quality Management > Setup

This program lets you design your own inspection tests that are used in the Quality Management module when inspecting work in progress (WIP) and purchase order receipts.

Program List > Quality Management > Setup

This program lets you establish the acceptance quality limits for critical, major and minor defects for each inspection level.

The AQL levels are defined to determine the number of items within the sample quantity that can fail the inspection test, before the entire batch is rejected.

Specifying the AQL levels is only necessary if the Sample basis field of the inspection level is defined as Sample quantity within the Inspection Level Review program.

Program List > Inventory > Setup

This program lets you capture and maintain details of stock items that your company uses or sells.

The QM inspection required option within the Tracking pane lets you include the stock code in quality inspections using the Inspection Engine within the Quality Management module.

This option is only available when the Lot traceability option is defined as Inspection required and the Traceable option as With inspection.

Program List > Quality Management > Inspection > Setup

Program List > Work in Progress > Setup

This program lets you define reasons that can be assigned when scrapping material during quality inspections using the Inspection Test Queue program or during labor postings using the Labor Posting program.

The following changes were made to accommodate the Inspection Engine functionality and will apply when the Quality Management module is used:

The word Scrap was replaced with Inspection at the pane name, form caption and various fields, to now read Inspection reason or Inspection reason maintenance.

This program was called Scrap Reasons before this release.

Accessible from the Post function within the WIP Inspection Maintenance program.

This program lets you inspect and maintain inspection references for made-in parent part items requiring inspection before actually accepting them into stock.

Once inspected, items can be accepted into stock, scrapped or returned for rework.

The following changes were made to accommodate the Inspection Engine functionality and will apply when the Quality Management module is used:

-

The Quality management section within the Inspection Quantities pane displays the inspection status, sample basis and quantity to accept, reject or quarantine.

-

The Count tab displays the counted quantity and whether the count has been completed.

-

The Inspection Level Select program is displayed when you select to count the quantity so that you can select the inspection level.

Accessible when selecting the Count option within the Purchase Order Receipts or WIP Inspection programs.

This program lets you select the inspection level when you count the quantity within the Purchase Order Receipts or WIP Inspection programs.

Program List > Purchase Orders > Purchase Order Processing

This program lets you process receipts against purchase orders that were captured using the Purchase Order Entry program.

The following changes were made to accommodate the Inspection Engine functionality and will apply when the Quality Management module is used:

-

The Inspection Level Select program is displayed when you select to count the quantity so that you can select the inspection level.

Program List > Purchase Orders > Purchase Order Processing

You use this program to receipt items from inspection into stock. You can inspect the goods and either accept, reject, or scrap them, before actually updating the stock on hand.

The following changes were made to accommodate the Inspection Engine functionality and will apply when the Quality Management module is used:

-

Inspection detail, such as the status, sample basis and quantity to accept, reject or quarantine is displayed at the Inspection Quantities pane.

-

The Count tab displays the counted quantity and whether the count has been completed.

-

The Inspect and Reject tabs are disabled as the inspection takes place in the Inspection Test Queue program.

-

The QM Return tab is used to return rejected stock to the supplier.

Program List > Quality Management > Processing

This programs lets the quality supervisor or manager assign the tests that will be executed per hierarchy level according to inspection type, warehouse, stock code or supply chain (customer or supplier) and to define the sample basis used for tests.

Program List > Work in Progress > Job Postings

This program lets you post time against a specific job.

The Scrap code listview column was renamed to Scrap reason.

Program List > Lot Traceability > Product Recall > Transaction Processing

This program lets you capture and maintain product recalls.

The Scrap reason code field was renamed to Scrap reason.

This program runs in the background and is not accessible to users.

When the Inspection Engine within the Quality Management module is used, the Inspection Archive utility program handles the archiving in these programs:

-

Inventory Period End

-

WIP Period End

-

Purge and Archive

Program List > Quality Management > Processing

This program displays all sample tests that were created using the Inspection Test Design program and allows inspectors to update the tests assigned to them.

Program List > Quality Management > Processing

This program displays all inspection tests that were designed using the Inspection Test Design program.

Program List > Quality Management > Inspection

This dashboard program is used by quality managers to view inspection information, e.g. test results and inspection quantities.

Operators must have access to the QMS View dashboard operator activity to view the inspection information on the dashboard.

Program List > Work in Progress > Browses

This program lets you create and maintain reason codes that can be used in various programs.

The window title and pane was renamed to Inspection Reasons (both were WIP Scrap Reasons before).

The Code column in the listview was renamed to Inspection reason.

The following indicates the business objects that are affected by this feature:

The Inspection Level Setup business object lets you define inspection hierarchies levels for your company as part of the Quality Management System. Inspection levels are used to establish the sample basis and tests for an inspection as well as the default inspector for these tests.

The Inspection Level Test Setup business object lets you define which inspection tests need to be performed for each inspection level for your company as part of the SYSPRO Quality Management system. To assign or delete tests against an inspection level, you need to have access to the warehouse that applies to that specific inspection level.

The Acceptance Quality Limit Setup business object populates pre-built data for the SYSPRO Quality Management system. This pre-built data is sourced from an script executed by the SQL Execute SQL Scripts program.

The SQM Inspection Creation business object lets you initiate and create a new Work in Progress or Purchase Orders inspection. The information that you need to indicate includes the WIP inspection reference or goods receipt number, the associated lot for the item that you want to inspect, stock code, quantity of items being inspected as well as the inspection level that you require.

The Inspection Test Queue business object lets you:

-

Submit the information for a test required to be performed against each sample test for the SQM inspection, when the Action element contains T and establishes if the sample test passes or fails inspection. Additionally, it also establishes if the SQM inspection passes or fails inspection and updates these inspections according to the inspection status with regards to passing or failing inspection.

-

To amend a test that was previously completed, when the sample basis is sample quantity and the sample test isn't already completed, when the Action element contains A.

-

Set an expected end date against a sample test, when the Action element contains D.

-

Assign an inspector against a test, when the Action element contains I. The inspector will be assigned according to the Apply Individual Test element:

-

When I, then the inspector will be applied to the individual test only.

-

When S, then the inspector will be applied to the sample test only.

-

When A, then the inspector will be applied to the sample test as well as all associated individual tests.

-

-

Assign a serial to a test when the stock item is serialized, when the Action element is S.

-

When the quality inspection originated from WIP inspection, then the Capture serials at end of WIP inspection must not be selected.

-

Add short instructions to a sample test, when the Action element is N.

-

Place an Inspection on hold , when the Action element is H.

The PO Purchase Order Receipts business object lets you process positive receipts against purchase orders. Items can be receipted into stock or into inspection, if they have been defined as requiring inspection or they are lot traceable items. Non-stocked lines can optionally be receipted into inspection.

The Goods in Inspection Returns business object lets you return goods into inspection that were previously rejected. Goods can be returned from the supplier if they were sent to the supplier when rejected.

If the item is serialized, the serial numbers to return can either be entered or be automatically selected. Items are receipted into inspection (using the business object PO Purchase Order Receipts) if they have been defined as requiring inspection or they are lot traceable items. Non-stocked lines can optionally be receipted into inspection.

The Goods in Inspection Counts business object lets you capture the quantity counted in inspection.

Items are receipted into inspection (using the business object PO Purchase Order Receipts) if they have been defined as requiring inspection or they are lot traceable items. Non-stocked lines can optionally be receipted into inspection.

The Goods in Inspection Rejects business object lets you reject goods that are in inspection. A reject code can be entered and the goods can optionally be returned to the supplier.

The Goods in Inspection Scraps business object lets you scrap goods that are in inspection. A reject code can be entered.

The PO Purchase Order Inspections business object lets you capture the quantity inspected against a GRN. Items are receipted into inspection (using the business object PO Purchase Order Receipts) if they have been defined as requiring inspection or they are lot traceable items. Non-stocked lines can optionally be receipted into inspection.

The WIP Inspection Scrap Maintenance business object lets you scrap a quantity for a WIP inspection reference together with a reason for scrapping.

A ledger entry is made for the transaction if Work in Progress is integrated to the General Ledger.

The WIP Inspection Rework business object lets you send a specified quantity of the inspected item for rework. This can be back to the original job, if it still exists, or to a new job and the job is created automatically.

A ledger entry is made for the transaction if Work in Progress is integrated to the General Ledger.

The WIP Inspection Accept into Stock business object lets you to accept a quantity of a job’s finished stock code into stock after completing an inspection.

This is a two-stage receipt facility for job receipts, similar to that found in purchase order receipts. This is only available if for stocked items where the Lot traceability is defined as Inspection required.

The Inspection Query business object lets you inspect test results at a management level in the Quality Management System.

While some believe every piece in an order must be inspected, it is mostly more cost effective to inspect a statistical sample. The acceptable quality levels (AQL) sampling framework can be used to determine whether to accept or reject an order based on defects found in the sample size. This section explains how to determine an appropriate sample size using three AQL inspection levels.

AQL standards

Acceptable Quality Levels (AQL) is a statistical quality control method that determines whether to accept or reject a production lot or ordered stock based on a representative sample size. AQL sets the lowest acceptable quality limit for goods, measured by the number of defects found in the sample size.

It is imperative that the correct sample size is used, as the wrong sample size could lead to inaccurate assessments and increased costs. The AQL standard provides guidelines for determining the appropriate sample size and maximum acceptable defects. Choosing the right sample size depends on factors like lot size, defect tolerance, and risk tolerance.

AQL Inspection levels

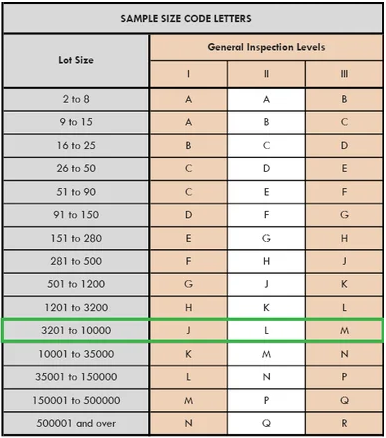

Each of the three general AQL inspection levels GI, GII and GIII indicate specific sample sizes for a non-destructive inspection.

GI, the most lenient inspection, may be sufficient when budget limitations restrict the duration of inspections, when suppliers or manufacturing consistently meet requirements and for low-value products or promotional goods that have minimal safety risks.

The GII inspection level is commonly chosen by businesses as it is suitable for the initial inspection of a lot, allowing businesses to assess if GII is still appropriate or if they need to adjust the inspection level.

As the GIII inspection level offers the largest sample size for your lot, it provides the highest coverage and therefore the best assurance and quality of acceptance sampling. It effectively reducing the risk of unintentionally accepting a lot with a higher number of defective items than initially identified during inspection.

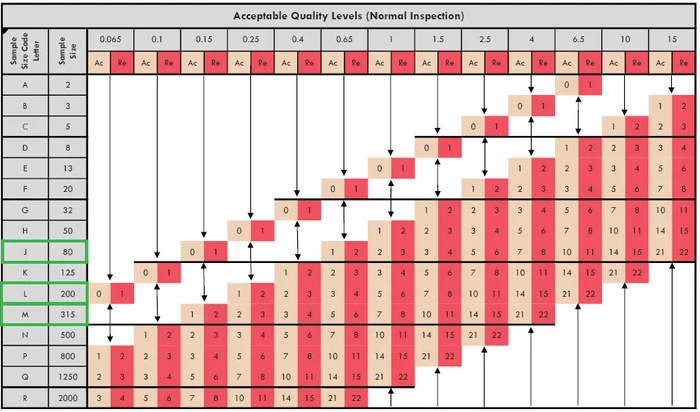

The diagram below indicates the inspection levels that correspond with the lot size.

For example:

A lot size of 5,000 would fall within the range of 3201 - 10000, which in turn means that the inspection level for GI indicates J, for GII it would be L and for GIII M would apply.

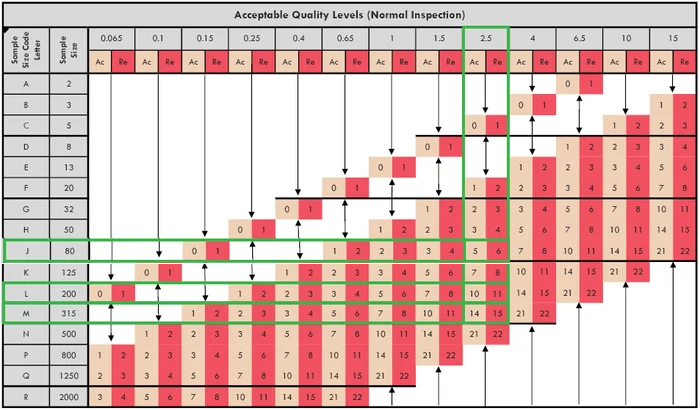

The table below helps you determine your AQL inspection level and sample size.

For example:

For a GI inspection, the sample size is 80.

For a GII level inspection, the sample size is 200. The accept and reject points increase with the sample size, meaning that with an AQL of 2.5, the accept point becomes 10 defects and the reject point becomes 11 defects.

For a GIII inspection, the sample size is 315. The acceptance point would be 14 defects and a rejection would become effective at 15 defects.

The general inspection level you choose will affect the time and resources required for the inspection. To establish your accept and reject points, you need to determine the acceptable quality levels for different types of defects. The acceptable quality level should vary based on the severity of each defect. For consumer goods, an AQL of 4 is often selected. Similarly, an AQL of 2.5 might be chosen for major defects, while a tolerance level of 0 may be set for critical defects, indicating a lower tolerance for more severe issues.

The diagram below depicts the accept (Ac) and reject (Re) levels based on the various AQL levels:

For example:

If an AQL of 2.5 is selected:

-

For a GI inspection: If 5 of 80 inspected items are defective, the batch would be accepted, but if 6 items are defective, the entire batch would be rejected.

-

For a GII inspection: If 10 of 200 inspected items are defective, the batch would be accepted, but if 11 items are defective, the entire batch would be rejected.

-

For a GII inspection: If 14 of 315 inspected items are defective, the batch would be accepted, but if 15 items are defective, the entire batch would be rejected.

Using SYSPRO

In SYSPRO the AQL levels are configured as follows:

-

The AQL level you want to use is defined against the stock code using the Acceptance Quality Limit program.

-

You can select the inspection level at the Field inspection level field when you design the inspection test using the Inspection Test Design program.

Conclusion

Some businesses mistakenly believe that every item in a lot must be inspected before shipping, but a smaller statistical sample often provides sufficient information for decision-making.

When choosing a QC sampling method or sample size you should consider the following:

-

Budget

-

Product type

-

Supplier history

Managing product quality is a continuous process, and you will probably need to adjust your AQLs throughout your relationship with your supplier.

Copyright © 2025 SYSPRO PTY Ltd.