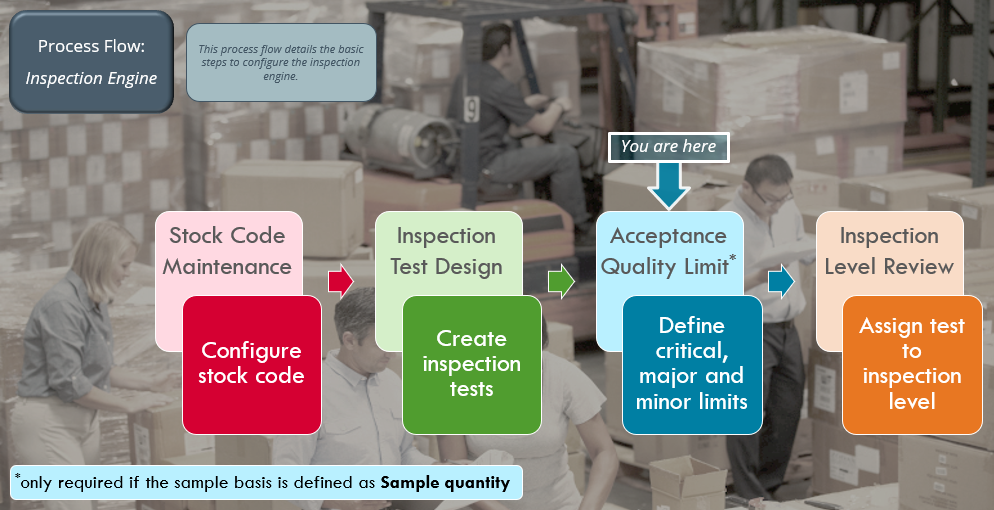

Acceptance Quality Limit

This program lets you establish the acceptance quality limits for critical, major and minor defects for each inspection level.

The AQL levels are defined to determine the number of items within the sample quantity that can fail the inspection test, before the entire batch is rejected.

Specifying the AQL levels is only necessary if the Sample basis field of the inspection level is defined as Sample quantity within the Inspection Level Review program.

Exploring

This program is accessed from the Program List of the SYSPRO menu:

- Program List > Quality Management > Setup

The acceptance quality limit is the level of defect that the business can accept in its product.

AQL sampling helps a business determine whether to accept or reject an order based on the number of defects found in the sample size. Every business needs to decide what the critical, major and minor defects are on its components, and what level of defects it can accept in its processes.

You can specify the accept / reject quantity for critical, major and minor defects within the Acceptance Quality Limit program.

The inspection test, also called inspection level test, is the test for the actual inspection of an individual item. Inspection tests are assigned to the sample test, which includes all inspection tests of the item. Once all individual inspection tests are done, the sample test is complete.

The test data, status and results of the individual inspection level tests are saved within the SqmIndTest table.

This encompasses the entire inspection that is performed on a purchase order or job that is received into inspection.

The inspection data, status and the results are saved within the SqmInspect table.

Starting

You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program).

Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

Controls access when adding an AQL limit in the Acceptance Quality Limit program.

Controls access to the maintenance of an AQL limit in the Acceptance Quality Limit program.

Controls access when deleting an AQL limit in the Acceptance Quality Limit program.

You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

The following configuration options in SYSPRO may affect processing within this program or feature, including whether certain fields and options are accessible.

To use this feature, the following setup option(s) must be enabled/defined:

Program List > Inventory > Setup - Tracking pane:

-

Quality management

-

QM inspection required

-

-

Lot traceability control

-

Lot traceability

This must be defined as Inspection required.

-

Traceable

This must be defined as With inspection.

-

Allow issues from multiple lots

-

-

Currently you can't define custom inspection levels. The available inspection levels are predefined and saved in the SqmInspectLvl table.

You will be able to define your own inspection levels in a following release of the software.

Solving

-

Access the Acceptance Quality Limit program.

-

Select the inspection level and plan type.

-

Select the stock code for which you want to create the inspection test(s).

-

Select the AQL level you want to apply to the inspection, e.g. critical, major or minor and enter the relevant values.

Currently you can't define custom inspection levels. The available inspection levels are predefined and saved in the SqmInspectLvl table.

You will be able to define your own inspection levels in a following release of the software.

Using

Referencing

This lets you enter or select a unique inspection level code.

| Field | Description |

|---|---|

|

Inspection level |

This displays the selected inspection level. Currently you can't define custom inspection levels. The available inspection levels are predefined and saved in the SqmInspectLvl table. You will be able to define your own inspection levels in a following release of the software. |

|

Description |

This displays the description of the selected inspection level. |

|

Plan type |

This displays the inspection plan. The plan type is saved in the SqmInspectLvl table and is currently defined as ISO-2859-1. |

|

Stock code |

This lets you select a stock code against which you want to define AQL levels per inspection level. |

|

Stock description |

This displays the description of the selected stock code. |

|

Critical level applies |

Enable this to specify a tolerance level for critical defects. Critical defects mean that a product is unusable and may put your business at serious risk of a product recall. The AQL standard provides guidelines for determining the maximum acceptable defects for the sample and batch size. |

|

Critical AQL |

This lets you specify the tolerance level for critical defects, i.e. how many items with a critical defect in a batch would cause the batch to fail the inspection. |

|

Major level applies |

Enable this to specify a tolerance level for major defects. Major defects are those which could adversely affect the function, performance or appearance of a product. |

|

Major AQL |

This lets you specify the tolerance level for major defects, i.e. how many items with a major defect in a batch would cause the batch to fail the inspection. |

|

Minor level applies |

Enable this to specify a tolerance level for minor defects. These are usually small, insignificant issues that won’t affect the function or form of the item. In most cases, the customer wouldn’t even notice a minor defect on a product. |

|

Minor AQL |

This lets you specify the tolerance level for minor defects, i.e. how many items with a minor defect in a batch would cause the batch to fail the inspection. |

Copyright © 2025 SYSPRO PTY Ltd.