You use this program to view extensive information relating to jobs held on file.

If you are using the Requirements Planning module, then you can use the WIP Query program to query jobs on your live data and to query jobs on the snapshot files created by the Requirements Calculation program.

If you are new to this query, then the following information will help you achieve the best results:

- The information shown is always up to date (i.e. the query will reflect the latest information for jobs that have been captured or maintained).

-

If you know the job code, then you can enter it directly and press the Tab or Enter key to view the information.

If you do not know the job code, then you can use the browse function to locate the job.

-

You can personalize this query in a number of ways. These include:

- setting preferences that affect what information is displayed. These settings can be retained for future use

- configuring property sheets (e.g. the section headed Job Details). This includes being able to sequence items by dragging them up or down, to show important items first

- configuring the Material Transactions, Purchase Orders, Operation Transactions, Tracking, Work Center Summary and WIP Booked listviews. This includes being able to sequence columns by dragging them left or right, sorting columns and changing column widths

- configuring the layout of the panes on the screen, including hiding or displaying panes

- Toolbar and menu

- Job Details

- Additional Information

- Material Transactions

- Purchase Orders

- Operation Transactions

- Tracking

- Work Center Summary

- WIP Booked

- Material Allocations

- Operation Allocations

- Custom Form

- Hints and Tips

- Notes and warnings

![[Note]](images/note.png)

|

|

|

If you are viewing a job from the snapshot files and you are running SYSPRO in a SQL environment, then not all options are available. See Note. |

|

| Field | Description | ||||||

|---|---|---|---|---|---|---|---|

| Options | |||||||

| Preferences | Select this to configure options that will determine the level of detail you want to view within the query. | ||||||

| Query | |||||||

| Material Allocations | Select this to view and maintain material allocations for the currently highlighted job. | ||||||

| Operation Allocations | Select this to view and maintain operation allocations for the currently highlighted job. | ||||||

| Hierarchy | Select this to view and maintain hierarchical details for the currently highlighted job. | ||||||

| Multi Level Query | Select this to use the WIP Multi-level Job Query program to view all the master jobs and sub jobs within a job structure. This option is only enabled for multi level jobs (i.e. jobs with sub jobs attached). | ||||||

| Archived Jobs | Select this to view details of archived jobs. | ||||||

| WIP Inspection | Select this to view information relating to WIP

inspection references using the WIP Inspection Maintenance program. This option is only available if you enabled the option: Work in Progress inspection required (Work in Progress Setup) and the job you are querying is for a made-in item defined as traceable or inspection required (Stock Codes). |

||||||

| Customer |

|

||||||

| Stock Code |

|

||||||

| Notes | |||||||

| Notes | Select this to assign free-format notations to the currently highlighted job (see WIP Job Notes). | ||||||

| Job | Indicate the job number you want to query. | ||||||

| Play | Select this to view any multimedia objects that has been assigned to the job. | ||||||

| Edit | Select this to maintain multimedia objects for the job (see Multimedia). | ||||||

| Notepad | Select this to add rich format text to the job (see Admin Notepad Editor (Rich Text)). | ||||||

| Graph | Select this to use the WIP Job Graph program to view a graphical representation of operations allocated to the job. | ||||||

| Refresh Job | Select this to reload and display the latest information for the selected job. |

This is displayed when you select the Preferences option from the Options menu.

![[Note]](images/note.png)

|

|

|

If you are viewing a job from the snapshot files and you are running SYSPRO in a SQL environment, then not all options are available. See Note. |

|

| Field | Description |

|---|---|

| View live jobs in browser | Select this to indicate whether you want to view live

jobs in a browser window. By default, only archived jobs can be viewed in a browser window. |

| Include purchase orders with zero quantities | Select this to include purchase order lines with zero quantities in the query (i.e. completed purchase order lines). |

| Save Preferences | Select this to save your selections against your operator code. |

| Close | Select this to save your selections for the current run of the program only. |

| Column | Description |

|---|---|

| Has sub jobs |

This indicates whether the job has sub jobs. A link is created in the WIP Job Master table/file from all sub jobs to the master job and from each sub job to its immediate parent job, irrespective of whether the master job is an hierarchical job. This link can be placed on the form using the Field Selector and selecting the Hierarchy Job field from the WIP Job Master fields. |

| Quantity |

|

| Notes |

Job notes The first three lines associated with the notes associated with the job are displayed. You can view/edit these notes by selecting the first line of the notes. |

| Column | Description | ||||||

|---|---|---|---|---|---|---|---|

| Original expected cost |

These are the original expected costs calculated when the job is created and are not changed when you maintain labor and material costs using the WIP Material Allocations - Browse and WIP Browse on Labor Allocations programs. Expected job costs are not automatically updated when a job quantity is changed using the Job Entry program. This is deliberate as you may choose to retain these costs for comparison purposed. To update the current expected costs (or original costs) you need to run the Expected Job Cost Recalculation program.

|

||||||

| Current expected costs |

These are the current job costs calculated by the Expected Job Cost Recalculation program.

Under normal circumstances, the Current expected cost will be the same as the Original expected cost. However, if the cost of an item has changed since the job was created or allocations were added or over issued, then the Current and Expected costs will differ. |

||||||

| Sales order |

This indicates the sales order attached to the job. This information is only displayed if the Sales Order has not been purged. If the sales order was cancelled (status '\'), but not purged, then the sales order information is still on file and will be displayed here. You can select this field to display the following:

|

||||||

| Unit selling price | When a job is created from a sales order, the selling price is taken from the sales order. However, the job's selling price is not updated when the sales order is subsequently maintained and the price is changed. | ||||||

| Reserved lots | Select this to view information on the lot numbers reserved for the job. | ||||||

| Reserved serials | Select this to view information on the serial numbers reserved for the job. | ||||||

| Capex |

This information is only displayed if the job was created from the Asset Capex Items program for a capex item requisition line.

|

||||||

| Tracking |

Displays lot and serial tracking information.

|

||||||

| Co-products |

Select this to view details of the co-products in the job. This only applies when the querying a job for a notional part. |

||||||

| Amendment journals |

Select this to view details of job amendment journals created for the job. This only applies when job amendment journals are required (Work in Progress Setup) and the job is not an MRP snapshot job. |

This displays details of transactions posted against the materials allocated to the job.

You can click on a line within the listview to select the Bins option to use the WIP Job Bin Query program to view material issues from bins to the job or to select the Serials option to use the WIP Job Serial Query program to view serials issued to the job.

Some of the information displayed includes the following:

| Column | Description | ||||

|---|---|---|---|---|---|

| Quantity issued |

The following applies when a phantom part is set to use a fixed parent quantity:

|

||||

| Reference designator | Indicate a reference to identify the component in an electrical

schematic (circuit diagram) or on a printed circuit board (PCB). This free format field usually consists of one or two letters followed by a number. Occasionally that number is then followed by a letter indicating that components are grouped or matched with each other. |

||||

| Assembly place | Indicates any additional sequence or reference for the placement of

the component within the assembly.

|

||||

| Item number | Indicates a number, description and/or reference of the item on the

assembly drawing.

|

||||

The information displayed in this pane relates to the line currently highlighted in the Material Transactions listview.

| Column | Description |

|---|---|

| Quantity issued |

This indicates the material quantity issued for the component. If progressive scrap is defined at operation level, then the material quantity issued is calculated as: Job quantity / (1 - Scrap%) * Qty per of the component attached to the operation |

This displays all outstanding purchase orders for the current job.

From the Options menu you can indicate whether you want to include purchase order lines with zero quantities.

This displays details of all transactions posted against the operations of the job.

Transactions include unplanned work, extra-ordinary work, rework, etc., performed against the job. The transactions are read from the WIPPST file, which reflects what actually happened.

See Activity considerations in Notes and warnings.

| Column | Description |

|---|---|

| Machine | Displays the machine code entered when posting labor. |

| Total set-up rate | Displays the total hourly set-up rate, calculated as:

set-up rate + fixed overhead rate + variable overhead rate |

| Total start-up rate | Displays the total hourly start-up rate, calculated

as: tart-up rate + fixed overhead rate + variable overhead rate |

| Total run rate | Displays the total hourly run rate, calculated

as: run rate + fixed overhead rate + variable overhead rate |

| Total teardown rate | Displays the total hourly teardown rate, calculated as: teardown rate + fixed overhead rate + variable overhead rate |

This displays allocated operation details for the current job. This indicates planned work performance.

Tracking information is read from the WIPLAL file, which are the Labor Allocations, so reflects what is setup in the labor allocations.

This is the same information as is reflected in the Job Status report.

You can select the following options by right clicking on a line:

-

Zoom (see WIP Browse on Labor Allocations)

-

Labor postings (see WIP Browse on Labor Details)

| Column | Description |

|---|---|

| Machine |

This displays the machine code captured against the labor allocation and not the machine code entered when posting labor. The machine code entered when posting labor is displayed on the Operation Transactions tab. |

This displays a summary of the time and value required and issued against each work center used for the job.

This displays details of the work in progress completed for the job to date.

| Column | Description |

|---|---|

| Labor value | When using standard costing, this value could be

negative, because when a job is receipted from Work in

Progress, the system calculates the material cost from the

Bill of Materials and then deducts this cost from the standard

cost. The balance of the cost is assumed to be labor. If the material value consumes the whole standard cost, then the remainder of the BOM cost, which is what is allocated to labor, is therefore negative. |

| Additional reference | This displays the Additional reference text entered when using the Job Receipts, Job Closure, Part Billings and Transfer Work in Progress programs. |

This displays details of material allocations currently allocated to the job. This is the same information that is displayed in the WIP Material Allocations - Browse program.

This includes the Override rev/rel column which indicates if the Override planned rev/rel in spec issue option has been selected. This is for ECC controlled stock codes when the Deplete oldest rev/rel first (Component) option has been enabled in the Bill of Materials Setup program.

This displays details of the operation allocations for the job. This is the same information that is displayed in the WIP Browse on Labor Allocations program.

This displays details of any custom form data that has been assigned to the job (Custom Form Data Entry).

-

This program can also be used to view details of jobs in the MRP snapshot files by running the WIP Query program from the SYSPRO Main Menu using Ctrl+R and entering WIPPEN SNAP={JobNumber}. For example, to view Job number 154 in the snapshot file, you would enter WIPPEN SNAP=154.

To view the same job in the live files, you would enter WIPPEN LIVE=154.

-

If you are using the Requirements Planning module and you successfully ran the Requirements Calculation program, then you can access the WIP Query program and view a Snapshot Job Query by selecting the Query Snapshot Job option from the Query function of the Job Review program.

-

You cannot view Jobs, Material allocations and Purchase order line details for Warehouses to which you are denied access (Operators).

-

You cannot view details of a job if you are denied access to the job classification of the job (Operators).

Operator access to the following activities within this program can be restricted. You configure this using the Operators program.

| Activity | Description |

|---|---|

| WIP Allow view of labor rates |

Controls whether an operator can view the operation Run rate, Set-up rate, Start-up rate and Teardown rate in the WIP Query program. The operator can still view the Fixed and Variable overheads. |

Password access to the following functions in this program may be defined in the Password Definition program. When defined, the password must be entered before you can access the function.

| Field | Description |

|---|---|

| WIP Deleting a job | This password restricts access to deleting a job using the Job Review,

Browse on Jobs or WIP Query programs. A job cannot be deleted using the Job Entry program, as you cannot delete the job you are currently maintaining. This is a transactional based password, which means the password is requested for each job you try to delete. |

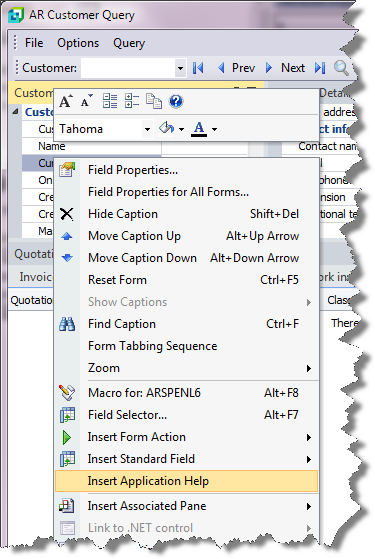

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.