You use this program to analyze the capacity utilization of your work centers.

The program can be accessed from either the Work in Progress or Requirements Planning modules. The window title will reflect either Snapshot - Load Levelling or WIP - Load Levelling, depending on the module from which the program is loaded.

The program can be viewed as a short-term capacity planning tool, enabling you to address and resolve capacity constraints that occur within the manufacturing time fence. It enables you to determine the seriousness of work center overloads and to identify the jobs contributing to the overload.

You can then maintain these jobs and alter the quantity to be made, change the start/finish dates, or move operations within the job by manipulating the queue time, move time or the operation elapsed time. If necessary, the work centre capacity can be adjusted to provide for overtime work, a machine breakdown, absenteeism, etc.

The Load Levelling program uses various data (specifically the work centre capacity calendar) to identify the total available capacity of the work centre. These include:

- The queue time of an operation from the work centre.

- The number of productive units the operation may use in the work centre.

-

The move time entered on the operation, or through the move time matrix

- The load on the work centre is caused by the operation's required capacity, which is calculated from the setup, startup, run, and teardown over the batch quantity of the job.

- The operation start and finish dates are established using the queue time and elapsed times with reference to the work centre calendar for non-working days.

- Move time between operations determines the start date of the next operation from the finish date of the current operation. Move times can be a negative number of days to provide for operation overlapping, but cannot be more negative than this operation's elapsed time.

-

The other major input to load levelling is from the Work in Progress jobs. Typically there will always be some past due jobs.

-

The dynamic capacity profile table is also used. When load levelling is required and you add, change or delete labor allocations, the WIP capacity profile is automatically updated. You can, however, recreate this file by running the Balance function of the WIP Period End program (enable the Recreate dynamic capacity profile file option) if you want to recalculate the entire WIP capacity profile.

For load levelling to operate successfully, it is essential that job bookings are up to date. Load levelling does not identify available capacity for any day prior to the current date.

The Job Status report can be used (by indicating a range of due dates) to determine the volume of past due jobs.

The Dispatch List can be used to generate a detailed report indicating the outstanding workload for each work center over a specified period of time.

| Field | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Identify Overloads | Select this to identify the overloaded work centers according to your selections in the Options pane. These work centers are displayed when you select the Overloaded work centers only option in the Work Centers list view pane. | ||||||||||

| Options | Indicate your selection requirements for identifying

overloaded work centers.

|

||||||||||

| Work Centers |

The list view defaults to displaying all your work centers regardless of your selections in the Options pane, until you select the Overloaded work centers only option. The date column in the list view indicates the first date on which an overload is detected for the work center. If accessed from the Work in Progress module, you can highlight entries for overloaded work centers in the list view and indicate one of the following from the Exit Capacity Profile window:

|

| Field | Description | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Toolbar and menu |

|

||||||||||||||||||||||||||||||

| Capacity Profile Graph |

This displays a graphical representation of the load assigned to a work center (i.e. reserved capacity, free capacity and capacity overloads). The graph displays the capacity required for each selected working day of the work centre. The capacity required is the total actual outstanding capacity per day. The scale of the graph is based on the normal capacity per day of the work centre, where Capacity indicates the capacity entered for that day using the Capacity Calendar Maintenance program. As each job is created, the operation load is placed on the dynamic capacity profile. Subcontract operations are not included in this table. For each working day, a record is added. The total capacity required per operation is divided by the elapsed time giving the daily capacity required. As work is performed against an operation, the dynamic capacity profile is immediately updated with the capacity used. As the planned start date of an operation is not necessarily the actual start date, the capacity used is added to the first planned day until the planned capacity and the actual capacity are equal, before adding the second day, etc. If the actual capacity for the operation exceeds the planned, the excess is added to the last day of the operation. |

||||||||||||||||||||||||||||||

| Capacity Profile | The following information is included in this list

view:

|

||||||||||||||||||||||||||||||

| Capacity Pegging |

|

This pane displays a summary of static information held against the work center, including general information, unit of measure information and productive units information.

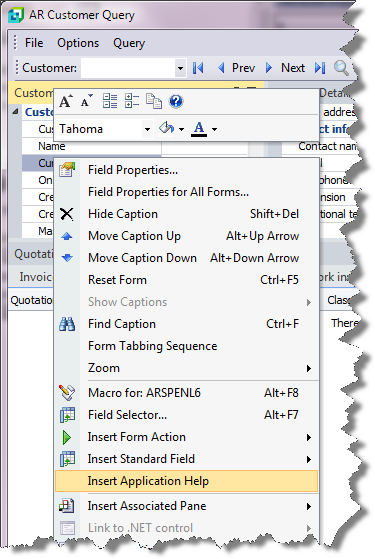

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.