Work in Progress Picking and Issuing

The Work in Progress Picking and Issuing feature is implemented as an extra step in the production process for better tracking and tracing of material items used to create a parent part. Stock for manufacturing can be picked from a specified bin location in the warehouse and automatically issued to a job once the pick is complete. Picks can be initiated as the stock is required within production.

Exploring

-

Optimized stock selection and transfer for production

-

Real time visibility of component stock used in the manufacturing and kitting processes

-

Increased visibility of stock consumed in production if automated issuing of picked components is enabled.

-

Efficient stock management in lean manufacturing, as it is moved to the production line as required.

The programs related to this feature are accessed from the Program List of the SYSPRO menu:

- Program List > Work in Progress

This is a bin transfer movement type that applies when you complete a pick. The quantity picked is transferred from the original location, which could be in the storage or picking areas of the warehouse, to the destination bin.

For Work in Progress Picking and Issuing, the destination bin can be defined against the operation within the Structures and Routings program, or when generating the pick note within the WIP Picking Options program.

This is the process of finding and extracting products from a warehouse bin that are used in the production process.

This is common in manufacturing or assembly environments where products move through various stages of completion. Work in Progress Picking and Issuing ensures that the necessary components or materials are available at each stage of production to prevent delays and keep the workflow smooth.

WIP is an abbreviation used for work in process, work in progress, goods in process, or in-process inventory which are a company's partially finished goods waiting for completion and eventual sale. These items are either just being fabricated or waiting for further processing in a queue or buffer storage.

Starting

To use this feature, the following setup option(s) must be enabled/defined:

Setup Options > Configuration > Distribution > Inventory

- Multiple bins

- Associate serials by bin

- Fixed bins

-

Record movements for bin transfers

This is not a prerequisite, but used for auditing and evaluation purposes.

- Show Warehouses (hyperlink)

- WIP picking cycle in use

Auto issue WIP pick

The Auto issue WIP pick setup option overrides any auto depletion setup options.

This means that once the Auto issue WIP pick setup option is enabled, your selection at the Apply automatic depletion in setup option is ignored (Setup Options > Preferences > Distribution > Inventory).

- Accounting for shortages

- Process as stock adjustments

- Process to lost and found warehouse

- Pick allocation override

- Lost and found warehouse

Setup Options > Configuration > Manufacturing > Work in Progress

- Reserve stock for confirmed jobs

Setup Options > Preferences > Manufacturing > Work in Progress

- Reserve lots for allocations

- Reserve serials for allocations

You can secure this feature by implementing a range of controls against the affected programs. Although not all these controls are applicable to each feature, they include the following:

- You restrict operator access to activities within a program using the Operator Maintenance program.

- You can restrict operator access to the fields within a program (configured using the Operator Maintenance program).

- You can restrict operator access to functions within a program using passwords (configured using the Password Definition program). When defined, the password must be entered before you can access the function.

- You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program). Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

- You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

- You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

-

Multiple jobs and operations can only be added to a pick if the same destination bin is used.

-

The destination bin must belong to a warehouse area where the area type is defined as W - Production/WIP.

-

Stock that is allocated to a pick must be located in a warehouse that is configured to use WIP picking, i.e. the WIP picking cycle in use setup option against the warehouse is enabled.

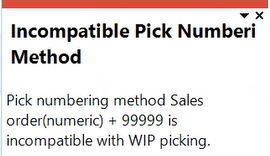

Solving

This error message is displayed if you want to use Work in Progress Picking and Issuing in a warehouse (i.e. select Yes at the WIP picking cycle in use field within the Warehouse Maintenance progam) and the PicksNumbering method is defined as Sales order + 99999 (Setup Options > Keys > Distribution - Inventory).

If you are using Order Picking and Work in Progress Picking and Issuing the Picks Numbering method must be defined as Numeric, as the Sales order + 99999 option would result in the sales order pick and WIP pick using the same pick number.

This option is only available if you have selected one single warehouse in the Warehouse selection area.

The selected warehouse must have the WIP picking cycle in use setup option enabled (Setup Options > Configuration > Distribution > Inventory > Show Warehouses).

The system prompts the user to create a WIP pick if the WIP picking cycle in use option is enabled against the job parent warehouse within the Warehouse Maintenance program (Setup Options > Configuration > Distribution > Inventory > Show Warehouses )

Yes, stock items from multiple bins and warehouses can be grouped together on one pick.

All the picked items will then be transferred to the same destination bin, which is the production bin.

-

If the material is not stocked in the same warehouse as the manufactured parent item, an immediate warehouse transfer is created once the pick is completed, i.e. the wip pick status is set to C - Picked.

-

If multiple warehouses are used as the source location, then the WIP picking cycle in usesetup option against those warehouses must be enabled to generate a pick. If this isn't enabled, the issuing of the stock will be done using kit or manual issues.

Yes, if the destination bin is the same. Multiple jobs and operations can only be added to a pick if the same destination bin is used.

Yes, a job can have multiple picks.

This enables lean manufacturing as it allows stock to be moved to the production line as required.

You can essentially reserve lots and serials for a pick by simply adding these to the pick when the pick is created. Once added, they will remain allocated to the pick until the pick is completed and the stock issued.

If you have started a pick and one of the lines can't be picked, you can remove it by doing the following:

-

If the pick status is in O - Outstanding status, select the pick status to start the pick.

The status will change to S - Started.

-

Edit the pick line by either right-clicking on the line or selecting the Edit button at the start of the line.

-

Select the Cancel line option to remove the line from the pick.

You can only remove a line from the pick once it has a status of S - Started.

You can't remove a line from a pick when the pick has a status of O - Outstanding or C - Picked.

You can override the bin, lot or serial that was allocated to the pick using the Syspro Desktop version as well as Syspro Espresso.

-

Launch the WIP Pick Maintenance program.

-

At the Pick field, enter or select the pick for which you want to change the stock allocation.

The selected pick's details and pick lines are displayed.

-

Select the Edit hyperlink at the Override allocation column in the Pick Detail Lineslistview.

The Edit hyperlink is only available (i.e. you can only allocate different stock to the pick) if the status of the pick line is O - Outstanding and the Pick allocation override setup option is enabled against the warehouse.

You can select the status to change the status of the pick line.

The WIP Pick Allocation Override program is displayed.

-

Enter the bin, lot or serial and if required, the quantity.

-

Select the Add to list option.

-

Select Yes at the pop-up message that prompts you to confirm if you want to accept the allocations.

You can only save the allocation once you have allocated the same stock quantity that was allocated before.

You are returned to the WIP Pick Maintenance program.

-

-

Exit the WIP Pick Maintenance program.

Use the Pick Amendment Journal program to generate a report of all pick lines where the original stock allocation was overridden.

-

Launch the Missions & Tasks or the Order Picking application.

-

At the Pick field, enter or select the pick for which you want to change the stock allocation.

The selected pick's details and pick lines are displayed.

-

Edit the pick line for which you want to change the stock allocation.

-

Select the Override allocations option.

The Override allocations option is only available (i.e. you can only allocate different stock to the pick) if the status of the pick line is O - Outstanding and the Pick allocation override setup option is enabled against the warehouse.

Select the Change line status option to change the status of the pick line.

The Override Pick Allocations application is displayed.

-

Enter the bin, lot or serial and if required, the quantity.

-

Select the Add line option.

The allocation detail line is added to the grid. You can select the Edit option to edit the line.

-

Once you have allocated the same stock quantity, you can select the Save line option.

You are returned to the Missions & Tasks or Order Picking application.

-

The status options that are displayed when right-clicking on a pick line are linked to the status of the pick header.

You can't start the pick for a line, if the status of the pick header is not S - Started.

Once the WIP pick is started, the status of pick lines is automatically set to S - Started as well.

Stock is issued once the pick is completed, i.e. the pick header and pick lines have a status of C - Picked. Once in C - Picked status, the quantity picked can't be changed as the stock has already been issued.

Yes, the quantity against a pick line can be changed while the pick and pick line is in S - Started status.

Once the pick is completed (i.e. the pick line and pick header has a status of C - Picked), the quantity against a pick line can't be changed, as the stock has already been issued.

The Auto issue WIP pick setup option overrides any auto depletion setup options.

This means that once the Auto issue WIP pick setup option is enabled, your selection at the Apply automatic depletion in setup option is ignored (Setup Options > Preferences > Distribution > Inventory).

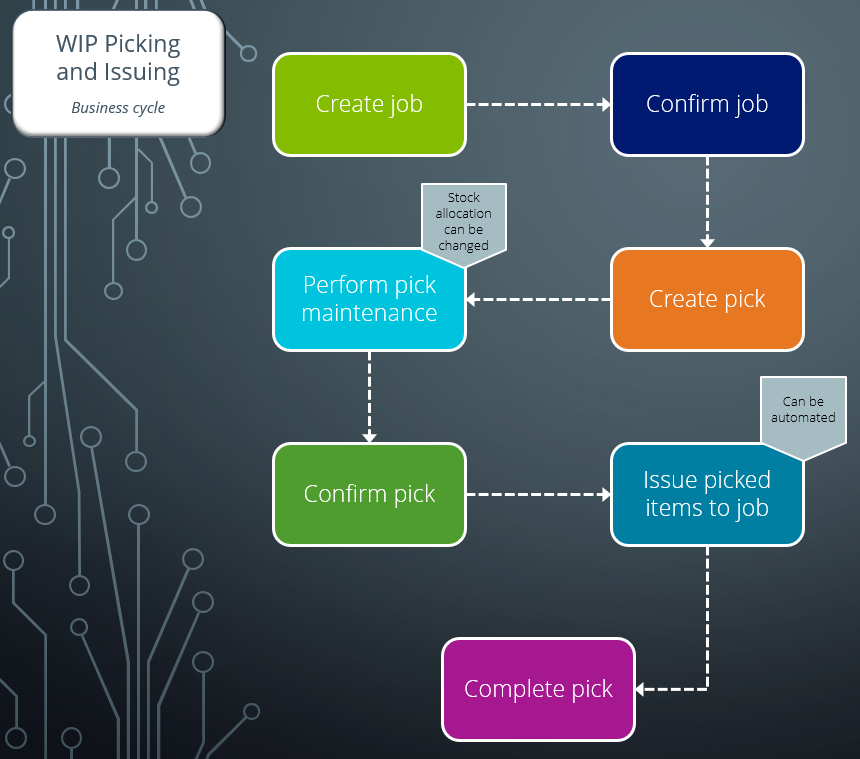

Using

-

Create a job using the Job Entry program.

-

Confirm the job using the Job Confirmation program.

-

Create a pick or add to an existing pick using the WIP Pick Review program.

-

Maintain the pick and change stock allocation using the WIP Pick Maintenance program.

-

Pick the stock items in the job allocation warehouse.

-

Confirm the pick using the WIP Pick Maintenance program.

-

Issue the picked items to the job using the Job Issues program.

This is done automatically if the Auto issue WIP pick setup option is enabled.

-

Complete the pick using the WIP Pick Maintenance program.

The following indicates areas in the product that may be affected by implementing this feature:

Setup Options > Configuration > Distribution > Inventory > Show Warehouses hyperlink

This program lets you capture and maintain details of warehouses required within the system.

The following fields have been added to the Warehouse Maintenance pane:

-

WIP picking cycle in use

-

Auto issue WIP pick

These setup options are only available when accessing the Warehouse Maintenance program from within the Setup Options program.

Program List > Bill of Materials > Setup

This program lets you define your bills of materials (i.e. the elements required in a sequence of manufacturing operations, as well as the structural relationships between parent and component parts).

We added the Production bin field in the Maintain Operations pane. This lets you enter the bin, where the stock that is used in production, is held. This defaults to the production bin defined against the warehouse of the parent stock code.

Accessible from the Change option within the WIP Browse on Labor Allocations program.

We added the Production bin field. This lets you enter the bin, where the stock that is used in production, is held. This defaults to the production bin defined against the warehouse of the parent stock code.

Program List > Work in Progress > WIP Picking

This program lets you maintain WIP picks.

Accessible from the Create a pick function within the WIP Pick Review program.

This program lets you decide how you want to pick stock items in the job allocation warehouse where the stock is kept that is used to assemble parent items.

Accessible from the Edit function at the Override Allocation column within the WIP Pick Maintenance program.

This program lets you override the stock item(s) originally allocated to the WIP pick.

Program List > Work in Progress > Job Postings

This program lets you create and maintain jobs in the Work in Progress module, as well as maintain material and operation allocations for jobs.

We have added the following validation:

-

You can't update the job quantity or warehouse if any allocations are linked to a WIP pick.

Program List > Work in Progress > Job Postings

This program lets you issue all component parts and labor allocations to a confirmed job.

We have added the following validation:

-

An error message is displayed when attempting to issue a kit to an allocation that is linked to an incomplete pick. This will ensure that kits aren’t issued to an allocation more than once.

Accessible from the Add option from the WIP Browse on Labor Allocations program.

We added the Production bin field. This lets you enter the bin, where the stock that is used in production, is held. This defaults to the production bin defined against the warehouse of the parent stock code.

Program List > Work in Progress > WIP Picking > Transaction Processing

This program lets you create picks for job allocations for warehouses that use the Work in Progress Picking and Issuing feature, (i.e. the WIP picking cycle in use setup option is enabled against the warehouse).

Program List > Sales Orders > Picking > Reports

This program lets you generate a list of sales order picks that can be filtered according to bins, warehouses, customers, sales orders or jobs, pick numbers, pick statuses and pick dates.

Program List > Work in Progress > WIP Picking > Transaction Processing

This program lets you view WIP pick headers and detail lines.

Program List > Sales Orders > Picking > Browses

This program lets you view the details of picks.

We added the Pick type filter within the Options pane so that you can select which picks you want to display in the listview.

The following indicates the business objects that are affected by this feature:

The Warehouse Area Maintenance business object lets you add, maintain and delete warehouse areas linked to a warehouse.

The SO Release Sales Orders to Picking business object lets you create a new pick on the sales order line as well as add the sales order line to the existing pick.

The WIP Job Creation and Maintenance business object lets you add, update or delete jobs.

Jobs can be created for stocked or non-stocked items. When creating a job for a stocked item, the labor and material allocations from the Bill of Materials can be attached to the job or they can be assigned manually. If allocations are being attached to the job, sub jobs can be created for all components in the structure against which it is indicated that a sub job must be raised.

The Inventory Movements (Bin Transfers) business object lets you capture a bin transfer transaction, which records the transfer of items from one bin location to another.

The Inventory Movements (WH Xfers OUT/IMM) business object lets you record the transfer of items from one warehouse to another.

The WIP Reserve Lots and Serials business object lets you reserve lots and serials against jobs.

The WIP Job Specific Issues business object lets you issue material to existing jobs and can be used to issue to both stocked and non-stocked material allocations.

The Post Key Information business object lets you update key information defined against the SYSPRO company where you are currently logged in.

The WIP Pick Status Change business object lets you change the status of a WIP pick and a pick line from open to confirm, cancel or complete.

The WIP Create Pick business object lets you create a new WIP pick or add the lines to an existing WIP pick.

The WIP Pick Allocation Override business object lets you override a stock item's original bin, lot or serial that was allocated for WIP picking. The updated allocation information is saved in the WhmPickDetail table.

The WIP Material Allocations business object lets you add, change or delete material allocations against existing jobs and can be used to maintain both stocked and non-stocked material allocations.

The WIP Job and Op Maintenance business object lets you add, change or delete labor allocations against existing jobs and can be used to maintain both internal and subcontract labor allocations.

The WIP Pick Quantity Review business object lets you review pick quantities according to the job number, stock code, warehouse, customer, product class, work center, delivery date, product bin and WIP branch.

Copyright © 2026 SYSPRO PTY Ltd.