WIP Picking Options

This program lets you decide how you want to pick stock items in the job allocation warehouse where the stock is kept that is used to assemble parent items.

Exploring

Things you can do in this program include:

- Create a pick

-

Add a job to an existing pick with the production bin

This program can't be run standalone and is accessed from the following program(s):

-

WIP Pick Review:

From the Create a pick function.

This is a bin transfer movement type that applies when you complete a pick. The quantity picked is transferred from the original location, which could be in the storage or picking areas of the warehouse, to the destination bin.

For Work in Progress Picking and Issuing, the destination bin can be defined against the operation within the Structures and Routings program, or when generating the pick note within the WIP Picking Options program.

Starting

You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program). Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

Controls access to the creation of picks in the WIP Pick Status Change business object.

Controls access to the addition of sales order lines to existing picks in the WIP Pick Status Change business object.

Controls access to the maintenance of pick statuses in the WIP Create Pick business object.

Controls access to the maintenance of the status for pick lines in the WIP Create Pick business object.

You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

The following configuration options in SYSPRO may affect processing within this program or feature, including whether certain fields and options are accessible.

The Setup Options program lets you configure how SYSPRO behaves across all modules. These settings can affect processing within this program.

Setup Options > Configuration > Distribution > Inventory

- Multiple bins

- Associate serials by bin

- Fixed bins

-

Record movements for bin transfers

This is not a prerequisite, but used for auditing and evaluation purposes.

- WIP picking cycle in use

- Auto issue WIP pick

- Accounting for shortages

- Process as stock adjustments

- Process to lost and found warehouse

- Pick allocation override

- Lost and found warehouse

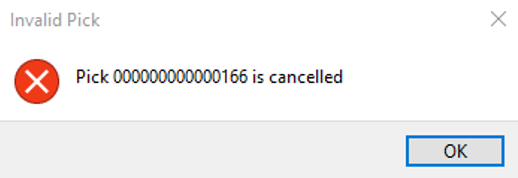

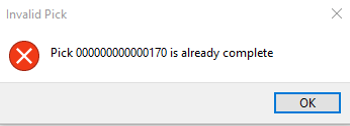

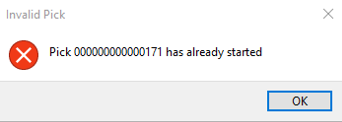

Solving

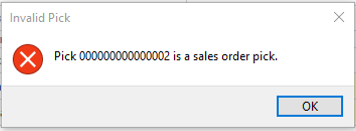

This error is displayed if you attempt to add a job or bill of material lines to a sales order pick.

Select OK and add the line(s) to a WIP pick that was created using the WIP Pick Review program.

A sales order pick is created using the Pick Review program.

Yes, if the destination bin is the same. Multiple jobs and operations can only be added to a pick if the same destination bin is used.

Yes, a job can have multiple picks.

This enables lean manufacturing as it allows stock to be moved to the production line as required.

Yes, stock items from multiple bins and warehouses can be grouped together on one pick.

All the picked items will then be transferred to the same destination bin, which is the production bin.

-

If the material is not stocked in the same warehouse as the manufactured parent item, an immediate warehouse transfer is created once the pick is completed, i.e. the wip pick status is set to C - Picked.

-

If multiple warehouses are used as the source location, then the WIP picking cycle in usesetup option against those warehouses must be enabled to generate a pick. If this isn't enabled, the issuing of the stock will be done using kit or manual issues.

Yes the amount at the Quantity to pick field within the WIP Pick Review program can be edited inline. The quantity displayed defaults to the quantity that is required, but can be changed to be less than the required amount, to facilitate multiple stock allocations.

The Quantity required field indicates the total quantity that must be picked.

The Quantity in picking field indicates the quantity that has already been allocated and picked.

Using

- At the time of releasing sales order lines for picking, you can use the Pick Review program to include the sales order lines in a pick.

Referencing

This saves the picking details you entered and opens the WIP Reserve Lots & Serials for Job program so that you can allocate or reserve lots and serials to the pick.

| Field | Description |

|---|---|

|

Selection |

This lets you select how to proceed with the picking process. This lets you create a pick for the selected job. Once the pick has been created, you maintain it using the WIP Pick Maintenance program. This lets you add job lines to an existing pick, which you can select at the Pick field. |

|

Pick |

This lets you select the pick to which you want to add the job or bill of material lines. This field only applies if you selected Add to a pick against the Selection field. |

|

Destination |

The fields in this section are only available if the production bin is not set on the operation. |

|

Destination bin |

This lets you select a destination bin, i.e. a bin where the stock is placed, using the Browse on Warehouse Bins program.

|

|

Destination warehouse |

This displays the job or assembly warehouse, which can't be changed. |

|

Picking sequence |

This lets you indicate the order in which the picking occurs in the warehouse: This lets you choose the bin as a picking sequence, which is typically used if the picker needs to go to various bins to retrieve the stock items. This instructs the picker to use the postman walk sequence to pick items in the warehouse. This instructs the picker to use the Z pick sequence to pick the stock items in the warehouse. The Postman walk sequence number and Z pick sequence numbers are maintained in the Warehouse Bins program. |

|

Print the picking slip |

This lets you print the picking slip for the picker to use in determining which products and quantities must be picked. |

|

Create mission and tasks |

This lets you create a mission with the associated task(s) for this sales order pick. This field is only available if the Enable for picking setup option is enabled. |

Copyright © 2026 SYSPRO PTY Ltd.