Kanban Automated Replenishment

SYSPRO's Kanban Automated Replenishment feature extends the Warehouse Management System to provide an automated stock replenishment solution for sales order picking and manufacturing production lines.

Exploring

When the minimum bin level is reached, stock replenishment movements are created automatically, replacing the stock that has been picked, consumed, counted or moved. This is achieved by creating bin-stock relationships and associating bins with specific warehouse areas.

When the stock level within a bin is below minimum, the system looks for available stock across configured warehouses, and determines which stock is most suitable using first in first out (FIFO) and first expired first out (FEFO) principles.

Stock movements are then generated using the Missions and Tasks feature. You can configure dispatch and receiving bins to allow for staged movements between the warehouses.

-

Continuous stock delivery for order processing and manufacturing:

The bin-stock relationship links the bin to the stock code to configure pull levels and pull quantity.

-

Reduction of wasted work / wasted time:

The Kanban Automated Replenishment feature automates the flow of stock through the warehouse for Order Picking and production.

-

Increased productivity and efficiency:

Manual movements around the warehouse are limited by automating bin and warehouse transfers and processing these using the Missions and Tasks feature.

The programs related to this feature are accessed from the Program List of the SYSPRO menu:

- Program List > Inventory

This refers to an inventory control system used in Just-In-Time manufacturing to track production and ensure timely replenishment of stocked parts and materials. It is a scheduling system designed to deliver the required components to the production or picking area just-in-time.

In a Kanban Automated Replenishment environment, a replenishment bin is released when a trigger or card is received from production. The bin is refilled with a fixed quantity of components immediately after the empty bin is received from production. Stock can be received from within the same warehouse (i.e. an intra-warehouse movement) or from a different warehouse (i.e. an inter-warehouse movement).

The Kanban Automated Replenishment pull level refers to the quantity of stock within a location that triggers a replenishment.

The Kanban Automated Replenishment pull quantity refers to the total amount of stock that must be moved to fulfill the replenishment of a location.

FIFO is an acronym for first in-first out. It's an inventory control method where the first items that come into the warehouse are the first items to leave, which means that the oldest stock is consumed first.

FEFO is an acronym for first expired-first out used in inventory management to describe a way of dealing with the logistics of products that have a limited shelf life. This means that perishable products or goods that have the earliest expiry date, are consumed first.

This is the process of finding and extracting products from a warehouse bin to fulfill customer sales orders.

This is a report that details the items required for picking and where to locate them.

A picking slip can only be printed once a pick has been created. Thereafter, you can print the pick slip at any time until it is complete.

A mission can be created for inventory putaway, sales order pick or cycle count transactions. Once missions and tasks are assigned to the employee or team they can be serviced using the Missions & Tasks application in SYSPRO Espresso (where operators can then view their tasks from a mobile device) or the WHM Review Mission Tasks program using the SYSPRO Desktop or SYSPRO Web UI (Avanti).

The system is updated in real time as the stock is allocated, physically moved and the task completed. Once all tasks are done, the mission can be completed.

Starting

To use this feature, the following setup option(s) must be enabled/defined:

Setup Options > Configuration > Distribution > Inventory

- Multiple bins

- Fixed bins

-

- Enable for cycle counting

- Enable for sales order picking

-

Enable for put-aways

If you have enabled the for the first time, you must save your changes, exit SYSPRO and log on again before proceeding with the setup options against the warehouse.

- Show Warehouses (hyperlink)

- Automated kanban replenishment

- Use kanban receiving bin

- Kanban receiving bin

- Use kanban dispatch bin

- Kanban dispatch bin

- Warehouses to replenish from

- Full goods in transit transfers facility

- Automatic depletion of lots by

You can secure this feature by implementing a range of controls against the affected programs. Although not all these controls are applicable to each feature, they include the following:

- You restrict operator access to activities within a program using the Operator Maintenance program.

- You can restrict operator access to the fields within a program (configured using the Operator Maintenance program).

- You can restrict operator access to functions within a program using passwords (configured using the Password Definition program). When defined, the password must be entered before you can access the function.

- You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program). Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

- You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

- You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

- Kanban Automated Replenishment is only available for bins using the Picking, Pick Replenishment and Production / WIP warehouse area types.

-

A bin can't be automatically replenished from a bin within the same warehouse area or warehouse area type.

Solving

This depends on the business processes used within the warehouses and the setup options you have enabled.

Receiving and dispatch bins are used for two-stage incoming and outgoing movements, where stock is first placed in a general receiving or dispatch bin before being allocated to the warehouse area where it's required.

Within the Warehouse Maintenance program:

-

If you only enable the Automated kanban replenishment option, you don't have to specify a receiving and dispatch bin.

-

If you enable the Use kanban dispatch bin option, then you have to specify a valid bin at the Kanban dispatch bin.

The same goes for the receiving bin.

In SYSPRO, we use the warehouse area and a predefined sequence of bins to determine the bin that is used for replenishment.

-

A bin in the picking or the production/WIP area of the warehouse will be replenished from a bin in the pick replenishment, then storage and lastly from the receiving area.

-

A bin in the pick replenishment area will first be replenished from a bin in the storage and then from the receiving area.

-

Stock items that use lots are allocated according to your selection at the Automatic depletion of lots by setup option. If Expiry date is selected, then lots are allocated from the current warehouse, first from the pick replenishment area, then storage, and lastly from the receiving warehouse area.

A bin can't be automatically replenished from a bin within the same warehouse area or warehouse area type.

If the required quantity of a stock item is not available in the current warehouse, then stock is located in the next warehouse according to the sequence in which warehouses were added within the Warehouse Maintenance program (Setup Options > Configuration > Distribution > Inventory - select the List of Warehouses hyperlink at the Warehouses to replenish from field).

When stock is replenished from within the same warehouse, a bin transfer is created automatically using the Missions and Tasks functionality. When stock is replenished from a different warehouse, a warehouse transfer is generated.

-

Open the Setup Options program (SYSPRO Ribbon bar > Setup).

-

Navigate to the Inventory Configuration form (Setup Options > Configuration > Distribution > Inventory).

-

Select the Show warehouses hyperlink at the section.

The Browse on Warehouses program is displayed.

-

Select the warehouse you want to maintain, followed by the Change function to open the Warehouse Maintenance program.

-

Enable the Automated kanban replenishment option.

-

From the Warehouses to replenish from option, select the List of warehouses hyperlink.

The Warehouse Maintenance program is displayed.

The Warehouse Maintenance program must be accessed from within the Setup Options program to configure Automated kanban replenishment.

-

The warehouse that you are currently maintaining is displayed in the Replenish from list by default. This lets you replenish from bins within the warehouse.

To replenish from another warehouse:

-

In the SYSPRO Web UI (Avanti) version:

Click on the Select icon to the left of the warehouse you want to add to the Replenish from list.

-

In the SYSPRO Desktop version:

Choose a warehouse from the Available List and use the Assign Selected option to add it to the Replenish from list.

-

-

To use receiving and dispatch bins, enable the Use kanban dispatch bin setup option and specify a valid bin at the Kanban dispatch bin field. Do the same for the receiving bin.

If the required quantity of a stock item is not available in the current warehouse, then stock is located in the next warehouse according to the sequence in which warehouses were added within the Warehouse Maintenance program (Setup Options > Configuration > Distribution > Inventory - select the List of Warehouses hyperlink at the Warehouses to replenish from field).

This can be due to one of the following reasons:

-

You have accessed the Warehouse Maintenance program from the Program List, instead of accessing it via the Show Warehouses hyperlink within the Setup Options program (Setup Options > Configuration > Distribution > Inventory).

-

You have enabled the for the first time.

If this is the case, save your changes in the Setup Options program, then exit SYSPRO and log on again before proceeding with the setup options against the warehouse (Setup Options > Configuration > Distribution > Inventory).

Yes the Goods in Transit module is required and the Full goods in transit transfers facility setup option must be enabled (Setup Options > Configuration > Distribution > Inventory).

Using

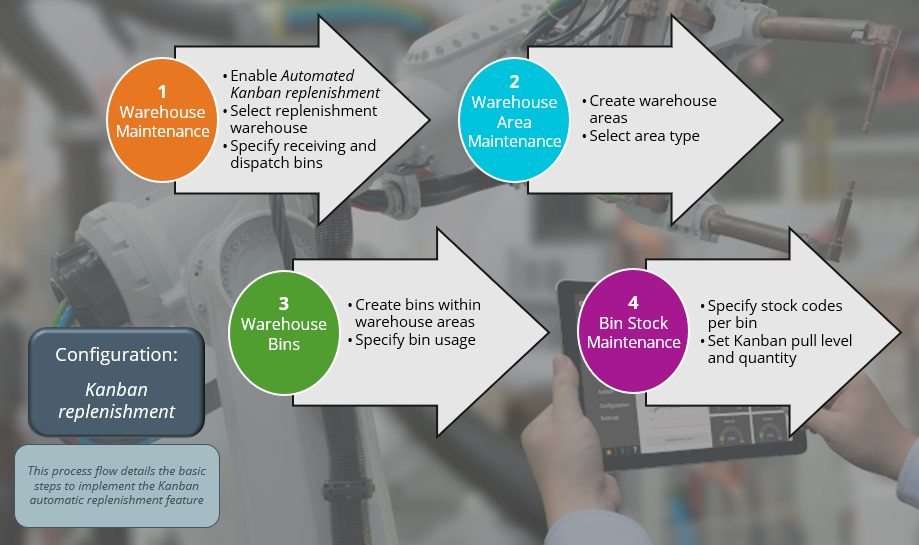

-

Configure the warehouse and indicate receiving and dispatch bins.

Step-by-step instructions

Step-by-step instructions

-

Open the Setup Options program (SYSPRO Ribbon bar > Setup).

-

Navigate to the Inventory Configuration form (Setup Options > Configuration > Distribution > Inventory).

-

Select the Show warehouses hyperlink at the section.

The Browse on Warehouses program is displayed.

-

Select the warehouse you want to maintain, followed by the Change function to open the Warehouse Maintenance program.

-

Enable the Automated kanban replenishment option.

-

From the Warehouses to replenish from option, select the List of warehouses hyperlink.

The Warehouse Maintenance program is displayed.

The Warehouse Maintenance program must be accessed from within the Setup Options program to configure Automated kanban replenishment.

-

The warehouse that you are currently maintaining is displayed in the Replenish from list by default. This lets you replenish from bins within the warehouse.

To replenish from another warehouse:

-

In the SYSPRO Web UI (Avanti) version:

Click on the Select icon to the left of the warehouse you want to add to the Replenish from list.

-

In the SYSPRO Desktop version:

Choose a warehouse from the Available List and use the Assign Selected option to add it to the Replenish from list.

-

-

To use receiving and dispatch bins, enable the Use kanban dispatch bin setup option and specify a valid bin at the Kanban dispatch bin field. Do the same for the receiving bin.

If the required quantity of a stock item is not available in the current warehouse, then stock is located in the next warehouse according to the sequence in which warehouses were added within the Warehouse Maintenance program (Setup Options > Configuration > Distribution > Inventory - select the List of Warehouses hyperlink at the Warehouses to replenish from field).

-

-

Create warehouse areas using the Warehouse Area Maintenance program.

-

Create bins within the warehouse areas.

Step by step instructions

Step by step instructions

-

Access the Warehouse Bins program.

-

Specify what the bin is used for by enabling one or more of the following fields:

-

Confirm as a kanban

-

Confirm as a pick

-

Confirm as a put bin

-

Dispatch bin

-

Receiving bin

-

-

-

Link the bin to stock codes and specify Kanban levels and quantities.

Step by step instructions

Step by step instructions

-

Access the Bin Stock Maintenance program.

-

Select the warehouse, stock codes, bins or warehouse areas and select Start Review.

-

The stock codes in the selected warehouse and bin are displayed in the grid, where you can add and maintain stock codes per warehouse.

-

For each stock code that you want to include in the Kanban Automated Replenishment, do the following:

-

Enable the Kanban active field.

-

At the Kanban pull level field, indicate the minimum stock on hand quantity that, when reached, will initiate the replenishment request.

-

At the Kanban pull quantity field, indicate the replenishment quantity that will be requested once the Kanban pull level is reached.

-

-

The following indicates areas in the product that may be affected by implementing this feature:

Program List > Inventory > Warehouse Management > Setup

This program enables Kanban Automated Replenishment by linking a stock code to a bin within the warehouse.

The Kanban pull level column indicates the minimum stock on hand quantity that, when reached, will initiate the replenishment request.

The Kanban pull quantity column indicates the replenishment quantity that will be requested once the Kanban pull level is reached.

The Replenishment in action column displays Yes when there are outstanding replenishment tasks.

Program List > Inventory > Setup

When accessing this program from within the Setup Options program, you can enable Kanban Automated Replenishment, specify the warehouse(s) from which stock is replenished and optionally indicate the Kanban dispatch and receiving bins.

Program List > Inventory > Warehouse Management > Setup

The following area types can be selected for a warehouse:

-

S - Storage

-

R - Receiving

-

P - Picking

-

I - Pick Replenishment

-

M - Marshaling

-

D - Dispatch

-

W - Production / WIP

-

Q - Quarantine

-

L - Lost and Found

-

T - Transit

-

C - Quality Check

-

E - Dispatch Storage

Program List > Inventory > Warehouse Management > Setup

You can view the bins (and the stock codes linked to the bins) that have been configured for Kanban Automated Replenishment within the warehouse by selecting the Kanban bin details hyperlink at the Kanban details field.

Program List > Inventory > Warehouse Management

All stock items and Kanban details for the stock items within a bin are displayed at the Bin Stock Details pane.

You can maintain stock items within the bin by selecting the ellipses hyperlink at the Change column.

You can only maintain bins within a warehouse for which the Automated kanban replenishment setup option is enabled (Program List > Inventory > Setup).

Program List > Inventory > Warehouse Management > Missions and Tasks

Kanban replenishment is a criterion that can be included when reviewing missions and tasks.

The Mission source column indicates whether the stock transfer originated from a Kanban replenishment transaction.

Program List > Inventory > Browses

A Yes at the Automated Kanban column indicates that the warehouse is configured for automated kanban replenishment. You can hover over the Yes in this column to view a list of warehouses that can be used to replenish stock.

The following indicates the business objects that are affected by this feature:

The WHM Mission Complete/Cancel business object lets you complete or cancel a putaway (e.g. a warehouse or bin transfer) and is called from the WHM Review Mission Tasks program.

The WHM Mission Query business object lets you query a mission, and the tasks associated with that mission, from the WhmMission table.

The utility program is used by various programs in the Work in Progress and Inventory Control modules to determine whether the bin quantity (i.e. OnHandQty1) is below the Kanban pull level quantity.

If the quantity is less, then the utility program determines from which bin from which the stock is replenished and creates a bin or warehouse transfer using the missions and tasks functionality.

A bin in the picking or the production/WIP area of the warehouse will be replenished from a bin in the pick replenishment, then storage and lastly from the receiving area.

A bin in the pick replenishment area will first be replenished from a bin in the storage and then from the receiving area.

Copyright © 2025 SYSPRO PTY Ltd.