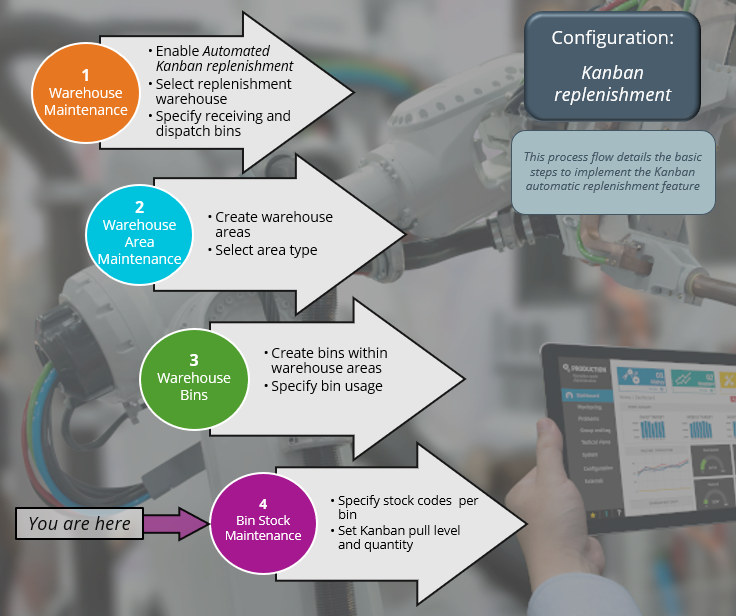

Bin Stock Maintenance

This program enables Kanban Automated Replenishment by linking a stock code to a bin within the warehouse.

Exploring

Things you can do in this program include:

-

Enable the Kanban Automated Replenishment functionality per stock code

-

Specify the minimum stock on hand quantity that will initiate a replenishment request

-

Specify the replenishment quantity that is requested once the minimum stock level is reached

This program is accessed from the Program List of the SYSPRO menu:

- Program List > Inventory > Warehouse Management > Setup

This refers to an inventory control system used in Just-In-Time manufacturing to track production and ensure timely replenishment of stocked parts and materials. It is a scheduling system designed to deliver the required components to the production or picking area just-in-time.

In a Kanban Automated Replenishment environment, a replenishment bin is released when a trigger or card is received from production. The bin is refilled with a fixed quantity of components immediately after the empty bin is received from production. Stock can be received from within the same warehouse (i.e. an intra-warehouse movement) or from a different warehouse (i.e. an inter-warehouse movement).

The Kanban Automated Replenishment pull level refers to the quantity of stock within a location that triggers a replenishment.

The Kanban Automated Replenishment pull quantity refers to the total amount of stock that must be moved to fulfill the replenishment of a location.

Starting

To use this feature, the following setup option(s) must be enabled/defined:

Setup Options > Configuration > Distribution > Inventory

- Multiple bins

- Fixed bins

-

- Enable for cycle counting

- Enable for sales order picking

-

Enable for put-aways

If you have enabled the for the first time, you must save your changes, exit SYSPRO and log on again before proceeding with the setup options against the warehouse.

- Show Warehouses (hyperlink)

- Automated kanban replenishment

- Use kanban receiving bin

- Kanban receiving bin

- Use kanban dispatch bin

- Kanban dispatch bin

- Warehouses to replenish from

- Full goods in transit transfers facility

- Automatic depletion of lots by

You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

Solving

This depends on the business processes used within the warehouses and the setup options you have enabled.

Receiving and dispatch bins are used for two-stage incoming and outgoing movements, where stock is first placed in a general receiving or dispatch bin before being allocated to the warehouse area where it's required.

Within the Warehouse Maintenance program:

-

If you only enable the Automated kanban replenishment option, you don't have to specify a receiving and dispatch bin.

-

If you enable the Use kanban dispatch bin option, then you have to specify a valid bin at the Kanban dispatch bin.

The same goes for the receiving bin.

In SYSPRO, we use the warehouse area and a predefined sequence of bins to determine the bin that is used for replenishment.

-

A bin in the picking or the production/WIP area of the warehouse will be replenished from a bin in the pick replenishment, then storage and lastly from the receiving area.

-

A bin in the pick replenishment area will first be replenished from a bin in the storage and then from the receiving area.

-

Stock items that use lots are allocated according to your selection at the Automatic depletion of lots by setup option. If Expiry date is selected, then lots are allocated from the current warehouse, first from the pick replenishment area, then storage, and lastly from the receiving warehouse area.

A bin can't be automatically replenished from a bin within the same warehouse area or warehouse area type.

If the required quantity of a stock item is not available in the current warehouse, then stock is located in the next warehouse according to the sequence in which warehouses were added within the Warehouse Maintenance program (Setup Options > Configuration > Distribution > Inventory - select the List of Warehouses hyperlink at the Warehouses to replenish from field).

When stock is replenished from within the same warehouse, a bin transfer is created automatically using the Missions and Tasks functionality. When stock is replenished from a different warehouse, a warehouse transfer is generated.

-

Open the Setup Options program (SYSPRO Ribbon bar > Setup).

-

Navigate to the Inventory Configuration form (Setup Options > Configuration > Distribution > Inventory).

-

Select the Show warehouses hyperlink at the section.

The Browse on Warehouses program is displayed.

-

Select the warehouse you want to maintain, followed by the Change function to open the Warehouse Maintenance program.

-

Enable the Automated kanban replenishment option.

-

From the Warehouses to replenish from option, select the List of warehouses hyperlink.

The Warehouse Maintenance program is displayed.

The Warehouse Maintenance program must be accessed from within the Setup Options program to configure Automated kanban replenishment.

-

The warehouse that you are currently maintaining is displayed in the Replenish from list by default. This lets you replenish from bins within the warehouse.

To replenish from another warehouse:

-

In the SYSPRO Web UI (Avanti) version:

Click on the Select icon to the left of the warehouse you want to add to the Replenish from list.

-

In the SYSPRO Desktop version:

Choose a warehouse from the Available List and use the Assign Selected option to add it to the Replenish from list.

-

-

To use receiving and dispatch bins, enable the Use kanban dispatch bin setup option and specify a valid bin at the Kanban dispatch bin field. Do the same for the receiving bin.

If the required quantity of a stock item is not available in the current warehouse, then stock is located in the next warehouse according to the sequence in which warehouses were added within the Warehouse Maintenance program (Setup Options > Configuration > Distribution > Inventory - select the List of Warehouses hyperlink at the Warehouses to replenish from field).

Using

-

Columns in a listview are sometimes hidden by default. You can reinstate them using the Field Chooser option from the context-sensitive menu (displayed by right-clicking a header column header in the listview). Select and drag the required column to a position in the listview header.

-

Press Ctrl+F1 within a listview or form to view a complete list of functions available.

Referencing

Start Review

Start Review

This displays data according to the selection criteria indicated. The function is enabled when you first load the program and then by selecting the Change Criteria option.

This lets you change the currently configured review criteria.

| Field | Description |

|---|---|

|

Warehouses |

This lets you select the warehouses in which you want to use the Kanban functionality. |

|

Stock codes |

This lets you select the stock codes you want to link to a bin. |

|

Bins |

This lets you select the bin you want to link to a stock code. |

|

Warehouse areas |

This lets you select the warehouse areas in which the bins are located. |

|

Warehouse area types |

This lets you select the type of warehouse areas in which the bin is located. Kanban Automated Replenishment is only available for bins using the Picking, Pick Replenishment and Production / WIP warehouse area types. |

Validate

Validate

This lets you validate the bin detail of a data record.

| Field | Description |

|---|---|

|

Warehouse |

This indicates the warehouse(s) in which you want to set up the Kanban functionality. |

|

Stock code |

This indicates the stock code that you want to link to the bin. |

|

Bin |

This indicates the bin that you want to link to the stock code and for which you want to specify the Kanban pull level and quantity. |

|

Kanban active |

This lets you enable the Kanban functionality for the bin. |

|

Kanban pull level |

This lets you specify the minimum stock on hand quantity that, when reached, will initiate the replenishment request. |

|

Kanban pull quantity |

This lets you specify the replenishment quantity that will be requested once the Kanban pull level is reached. |

|

Use full containers only |

This functionality is not yet available, but will be included in one of the following phases. |

|

Warehouse area |

This indicates the warehouse area code. |

|

Warehouse area description |

This indicates the description for the warehouse area. |

|

Warehouse area type |

This indicates the category and purpose of the warehouse area. Kanban Automated Replenishment is only available for bins using the Picking, Pick Replenishment and Production / WIP warehouse area types. |

|

Replenish in action |

A Yes in this column indicates that there are outstanding replenishment tasks. |

|

Unit of measure |

This indicates the unit of measure of the stock code. |

Copyright © 2025 SYSPRO PTY Ltd.