Product Configurator

The Product Configurator module lets you predefine possible product configurations that are made-to-order, assembled-to-order or sold according to the customer's specifications. Once the product expert or engineer has created the configuration, operators can then use the selection criteria to design or customize the product as required by the customer.

Exploring

-

Product configurations can be defined for both stocked and non-stocked items.

-

Predefined product configurations minimize configuration errors and ensure that an accurate bill of materials is created.

-

The requirement for experts' involvement in routine transactions is reduced.

-

Product configurations can be stored in a library for easy retrieval and reuse.

Product parameters are typically defined by a product expert using the Product Configurator Maintenance program. These parameters include the selection criteria, operations, components and dependencies (i.e. inter-relationships) between the components used to create each item.

Once a product configuration has been created and deployed, the Product Configurator Wizard can then be accessed to design or customize products within one of the following processes:

-

At point of sale using the Sales Order Entry program:

You can select the Configure link of the Configurator field in the Stocked Line Information or Non-stocked Line Information panes.

-

When preparing a quote using the Quotations program:

You can select the Configure link at the Configurator field in the Stocked and Non-stocked tabs of the Quotation Lines pane.

-

When defining components and operations for a non-stocked item using the Estimates program:

You can select the Configurator toolbar function.

-

When creating and maintaining jobs using the Job Entry program:

You can select the Configure link at the Configurator field in the Links section of the Job Details pane.

-

When defining the bills of materials using the Structures and Routings program:

You can select the Configurator toolbar button.

For convenient retrieval and reuse, valid product configurations (defined either by product experts in the Product Configurator Maintenance or operators using the Product Configurator Wizard) can be stored in a library.

The programs related to this feature are accessed from the Program List of the SYSPRO menu:

- Program List > Product Configurator

A product configurator assists you in selecting options for a product to meet the individual needs of your customers. It automates the process of creating quotes and sales orders, thereby speeding up the time line for customer service and getting the item into production.

The configuration tree-structure of the SYSPRO Product Configurator is made up of the following:

This is a classification of similar criteria, such as the type or color of an item. The grouping is called a selection (e.g. color) and the available choices within a selection (e.g. red, blue and green) are referred to as the criteria.

When you run the configuration, you review the criteria available and make specific selections. As you select the criteria, the remaining options, components and operations you can choose from, decrease accordingly. As options, components and operations can be linked to selection criteria, their selection availability is dependent on the criterion chosen.

An option consists of one or more similar components or operations that can be automatically or optionally included in the configured product.

Required quantities and selection criteria dependencies can be defined at option level so that these are applied to the components or operations within the option. The actual components or operations make up the end product's bill of material and determine the final cost.

If there is more than one operation, you can specify time requirements for components to ensure the component is made at the beginning of a specific operation or a certain number of days before the job is scheduled to be completed.

You must define at least one option for a configuration.

These are stocked or non-stocked items which are required to manufacture the configured product.

A component can be included multiple times within the same configuration and can be made dependent on selection criteria or a previous component in the sequence. The availability of a particular component during configuration depends on the selection criteria or components that were previously chosen.

A component can be mandatory (automatically included in the configuration and the BOM) or optional (the operator decides whether to include it in the BOM).

This relates to work that must be carried out (internally or sub-contracted) at a particular work center to manufacture the configured product using the selected components.

An operation can be dependent on a component or a selection criterion, and can be defined as mandatory (automatically included) or optional.

A link is used to create dependencies between selection criteria and components so that subsequent options or operations can be defined. There are two types of links:

-

A global link makes a subsequent option, component or operation available whenever a component is selected with these dependencies.

-

A specific link only becomes valid whenever a specific instance of the component is selected. This is used if the same component is used in different options, operations or with other components.

Starting

To use this feature, the following module(s) must be installed according to the terms of your software license agreement:

-

Inventory Control

-

Product Configurator

You can secure this feature by implementing a range of controls against the affected programs. Although not all these controls are applicable to each feature, they include the following:

- You restrict operator access to activities within a program using the Operator Maintenance program.

- You can restrict operator access to the fields within a program (configured using the Operator Maintenance program).

- You can restrict operator access to functions within a program using passwords (configured using the Password Definition program). When defined, the password must be entered before you can access the function.

- You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program). Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

- You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

- You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

Solving

This message is displayed in the Product Configurator Maintenance program when creating a new product configuration, if you attempt to add selections and criteria (or options and components) before saving the information already entered in the General, Options and Defaults tabs.

Save the static information entered within the General, Options or Defaults tabs before selecting the Add hyperlink in the Selections and criteria or Options and Components tab.

This message is displayed in the Product Configurator Maintenance program if you don't assign a parent for a configuration intended to be used in the Work in Progress module.

A product configuration that is used in the Work in Progress module requires a parent part with one or more associated components.

When the product configuration is used in the Work in Progress module, ensure the following:

-

The Work in progress option is enabled (General tab at the Where used section).

-

The Stocked, Non-stocked or Both stocked & non-stocked option at the Type field is selected (Options tab at the Parent section).

This message is displayed in the Product Configurator Wizard program if you select a product configuration at the Configuration Code field that has a future effective date.

Select OK to return to the Product Configurator Wizard window and ensure that you select an available product configuration (i.e. the availability start and expiry dates are within range).

This message is displayed in the Product Configurator Wizard program if you select a product configuration at the Configuration Code field that isn't deployed yet (i.e. its currently in development or being maintained by a product expert, engineer or estimator).

Select OK to return to the Product Configurator Wizard window and ensure that the relevant operator within the manufacturing or engineering department deploys the configuration before accessing it via the Product Configurator Wizard program.

If the product configuration is under development, the value in the Status field reflects as 2 - Under development, whereas a deployed product configuration reflects a status of 1 - Available to use.

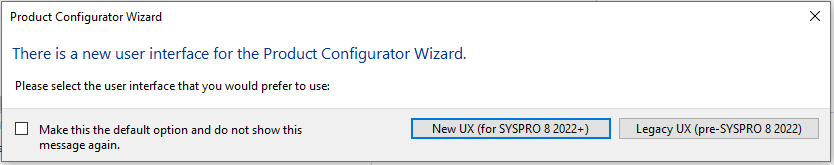

This message is displayed when you select the Configure link or button to customize a product from within one of the following programs:

-

Sales Order Entry

-

Quotations

-

Estimates

-

Structures and Routings

-

Job Entry

Depending on your requirements, proceed as follows:

-

Select New UX to use the Product Configurator Wizard program to create a customized product.

- Select Legacy UX to use Configurator Wizard program to create a customized product.

The Configurator Wizard program will be discontinued in the following release.

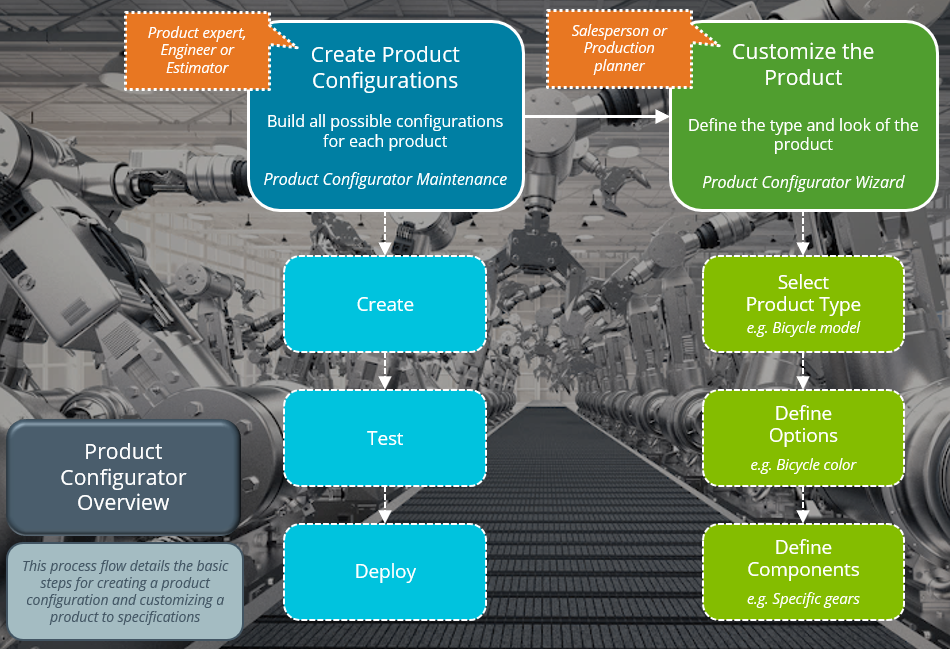

The Product Configurator is used for two different processes:

-

Creating a product configuration

-

Customizing a product using the configuration framework

The product expert, engineer, or estimator predefines and creates all possible product configurations using the Product Configurator Maintenance program. This consists of three steps:

-

Creating the configurations with all selections, options, possible components and operations. Links can be used to create dependencies between the items and to define subsequent options or components.

-

Testing the configuration using the Product Configurator Wizard program to ensure that all possible product customizations can be achieved.

-

Deploying the configuration so that it can be accessed by sales personnel, production planners, etc.

Sales personnel, job schedulers and production planners manipulate the configuration to create a customized product using the Product Configurator Wizard program. The number of steps depend on the product that you are configuring, but include the following:

-

Making selections and defining criteria that determine the type or form of the product.

-

Choosing from the available options and operations.

-

Defining required components based on the options you have selected.

No. None of the setup options require configuration to use the Product Configurator Maintenance or Product Configurator Wizard program.

No. The web-based Product Configurator is no longer supported - you must use the new Product Configurator Maintenance program in SYSPRO Avanti to create product configurations.

The setup options within the Product configurator web setup section are currently unavailable as they are no longer required but earmarked for future development.

The previous Configurator Wizard program has been replaced with the Product Configurator Wizard program, which includes the following enhancements:

-

Criteria that has been selected can be modified from within the listview and invalid selections are highlighted so that these can be adjusted.

-

The running merchandise and labor totals are displayed and updated as selections are made or changed.

-

Multimedia images of criteria are displayed in the listview.

-

Already selected and mandatory components and operations are displayed in a listview for easy reference.

-

The Review function lets you view a printable list of the all selections, criteria, options, components and operations you have chosen for the current configuration.

The web-based Product Configurator is no longer supported - you must use the new Product Configurator Maintenance program in SYSPRO Avanti to create product configurations.

This typically applies to product experts, engineers and estimators.

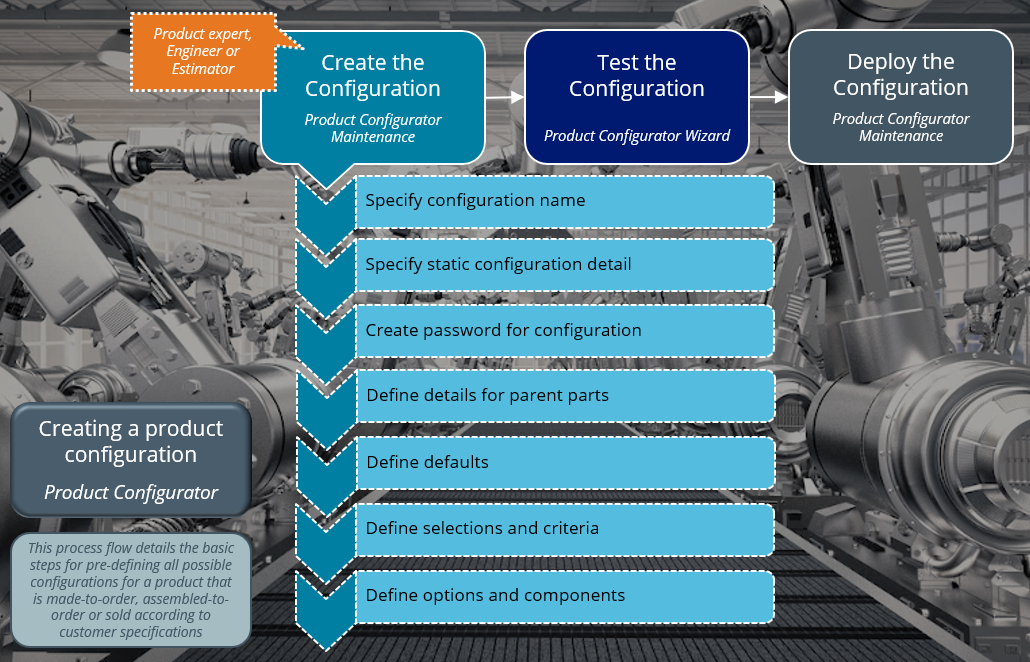

The following is a step-by-step process for a product engineer or estimator to create a template or model for a product configuration. This configuration can then be used by a salesperson or production planner to design or customize a product according to the required specifications.

This powerful tool enables you to create selections and criteria that enable non-technical people to customize a product. The selections are available choices in the form of questions (e.g. type of bicycle) and the criteria are the decisions or specifications in the form of answers (e.g. racing bike). A salesperson or production planner can select the answers to customize the product.

Proceed as follows to create a product configuration:

-

Open the Product Configurator Maintenance program (Program List > Product Configurator > Setup).

-

Indicate a name for the configuration that you want to create in the Configuration toolbar field.

-

Enter the static information at the General tab.

Step-by-step instructions

Step-by-step instructions

-

Indicate the Description, Comment, Engineer and Status.

-

Under the Availability drop-down, indicate the Start and Expiry dates for the configuration.

-

Under the Where-used drop-down, indicate the SYSPRO modules that can access the configuration.

A salesperson can access the Product Configurator Wizard from the following modules:

-

Sales Orders - via the Sales Order Entry program

-

Quotations - via the Quotations program

A production planner can access the Product Configurator Wizard from the following modules:

-

Quotations - via the Estimates program

-

Work in Progress - via the Job Entry program

-

Bill of Materials - via the Structures and Routings program

-

- You have to save the information before proceeding to the next tabs.

-

-

Select the Password function to create a password that must be supplied when the Product Configurator Wizard program is accessed from within a program.

-

At the Options tab, select configuration options, indicate details for parent parts and specify information for sales order documents.

Step-by-step instructions

Step-by-step instructions

-

Indicate if the quantity and warehouse can be specified at run time (i.e. when the product is customized) at the Ask quantity required and Ask warehouse fields.

-

Select whether alternate stock and warehouses an be specified at run time at the Allow alternate stock and Allow alternate warehouse fields.

-

Enable the comment fields to include selection criteria or user comments against a configuration.

-

Enable the Retain configuration libraries option to save customized product configurations in a library for repeated use.

-

At the Parent section you can indicate the types of parent parts that can be created and how they can be created.

This is not applicable if the parent Type is defined as None.

-

Indicate the various documents where you want to print a discount miscellaneous charge line for this specific configuration at the Sales orders section.

This section is only applicable if this configuration is to be used within the Sales Orders module (i.e. the Sales order option is selected against the Where-used section).

-

-

Indicate the default component warehouse, product class, Work in Progress and Bill of Materials details within the Defaults tab.

Step-by-step instructions

Step-by-step instructions

-

Indicate the default warehouse according to which you want to draw the stocked components against the Component warehouse field.

-

Indicate the default product class to assign to the stocked, non-stocked, labor and discount components or operations associated with this configuration.

-

Within the Work in progress section:

This only applies if the Type associated with the parent is defined as Stocked, Non-stocked or Both stocked & non-stocked.

-

Indicate the groups of jobs that you want to assign to this configuration using the Classification field.

-

Indicate the priority of the job by indicating a number from the range of 1 to 99 using the Job priority field.

1 indicates the lowest priority and 99 the highest priority.

-

Indicate the ledger account using the GL account field according to which the Work in Progress values must be posted to once a job is created.

-

There are various options that give you the ability to determine whether you want to include sequence checking on operations when creating a job, to confirm or place a job on hold by default.

This only applies if this configuration is used within the Work in Progress module (i.e. the Work in progress option is selected against the Where-used section).

-

-

In the Parent section, indicate the default product class that is used when generating a parent part.

This field only applies if the Use product class inventory defaults option at the Options tab is enabled .

-

Within the Bill of Materials section:

This section only applies if the configuration is used within the Bill of Materials module (i.e. the Bill of materials structures and routings option is selected against the Where-used section).

-

Indicate the default route to use when creating a bill of materials for the generated parent part for this configuration.

-

Indicate whether a salesperson has the ability to change the default routing for this configuration.

This only applies if the Alternate routings setup option is enabled (Setup Options > Preferences > Manufacturing > Bill of Materials).

-

-

-

Use the Selections and criteria tab to define the framework for the product configuration. The selections created here will be used as questions when customizing the product and the criteria against each selection serve as the answers.

Example

Example

The following aspects could be used when creating the selections for the framework of a Gate configuration:

-

Color

-

Dimensions (width and height)

-

Lock type

Within the color selection, the following particulars could be used when creating the criteria:

-

Black

-

Grey

Step-by-step instructions

Step-by-step instructions

-

To create a new selection:

-

Select the Add hyperlink against the first record in the listview.

This loads the Maintain/Add Selection window.

-

Indicate all relevant information and whether this is a Mandatory or Optional selection (i.e. whether this option must be selected in the Product Configurator Wizard).

-

Save the selection.

-

Once the selection is saved, you can select the hyperlinks to copy and edit the selection.

-

Select the Play hyperlink within the Multimedia column to load the multimedia (i.e. images, videos and documents) associated with a selection.

-

-

To add criteria for a single selection:

-

Select the Add hyperlink for the selection.

This loads the Maintain/Add Criteria window.

-

Indicate the relevant information for the criterion.

-

-

-

Use the Options and components tab to define the options associated with the configuration.

Step-by-step instructions

Step-by-step instructions

-

To add an option for a configuration:

-

Select the Add hyperlink against the first record (i.e. configuration) to associate an option for existing selections and criteria.

This loads the Maintain/Add Option window.

-

Indicate the name you want to associate with the option at the Description field.

-

Indicate whether you want to add an component or a component at the Option type field.

-

Indicate whether you require to define minimum or maximum number of components or operations by selecting the Ranges to be used in this option check box.

This enables the Component quantity section.

-

Indicate the information surrounding the offset that can be defined according to operation or the number of days by using the Component offset section.

-

Indicate the current and new sequence for the option under the Sequence section.

Exercise caution when changing the option's sequence as this as an effect on dependency links.

-

Save the component or operation.

-

-

To associate a component or operation with an option:

-

Select the Add hyperlink for the newly added option.

This loads the Maintain Operation or Maintain/Add Component window.

The window that is displayed depends on whether you selected List of operations or List of components when you created this option within the Maintain/Add Option window.

-

Indicate the relevant information and save your changes once you've defined the component or option.

-

You can also add calculations for operations and components.

-

-

To create a link between various criteria and the option that you've just added:

-

Select the hyperlink associated with the name of the component or option as accessible via the Configuration column.

A context-sensitive menu is displayed.

-

Select the Dependencies option.

-

Select the Selection criteria option to create links between the criteria (i.e. options) associated with the selections (i.e. questions) and the operation or component.

This loads the Dependent Selection Criteria window.

This is applicable to both components and operations.

-

Select the Components option to create links between one component with one or more other components.

You have the ability to define the relevant calculations for this configuration via the window that is loaded once you've selected the browse icon alongside the Components field.

This loads the Configurator Component Dependencies window.

This is only applicable to components.

-

-

-

You've successfully created a product configuration.

You can test the configuration using the Product Configurator Wizard program (Program List > Product Configurator) to ensure that the product can be customized using the framework and preferences you created.

-

Once tested, you can deploy the product configuration by selecting Available to use at the Status field of the General tab within the Product Configurator Maintenance program.

Calculations can be added to components and operations within a configuration.

-

Open the Product Configurator Maintenance program (Program List > Product Configurator > Setup).

-

In the Options and components listview, select the operation or component according to which you want to add a calculation.

-

Select the Add hyperlink associated with the selected operation or component.

This loads the Maintain/Add Component or Maintain Operation window depending on your selection to add either a component or operation.

-

Indicate the details for this new component or operation.

-

For a component, select the Calculations attached option so that you can use the Component Calculations function.

For an operation, you don't need to select any options before enabling the Operation Calculations function.

-

Select the Component Calculations function to load the Component Calculations window.

or

Select the Operation Calculations function to load the Operation Calculations window.

-

Indicate the calculation that you want to create for the particular component as illustrated in the format as indicated below:

For example:

Val2 = Sel003 x 4

where Val2 represents Result, Sel003 represents Field and 4 represents Field2.

The multiplication operation (i.e. the x symbol) is represented by Op1.

Sel003 represents the unique code for the third selection (i.e. question) as defined within the Selections and criteria tab.

You can indicate as many as four different fields and three different operations.

-

If required:

-

Select Insert to add another calculation for this component or operation.

-

Select Copy Calcs to copy an existing calculation.

-

Select the Ignore component option in the toolbar to exclude the component from selection (if the calculated quantity is zero or if the calculated quantity falls outside the minimum or maximum quantity or run time range).

-

-

Close this window once you've added the calculations.

-

Select Save within the Maintain/Add Component window.

You've successfully added a calculation for a component or operation associated with a configuration.

This applies to product experts, engineers and estimators.

Once you have successfully created a product configuration, you can then test and deploy it.

To test the product configuration:

-

Access the Product Configurator Wizard program from the Program List (Program List > Product Configurator).

-

Select the product configuration you want to test at the Configuration field.

-

Work through the selections, criteria, options and components to ensure that the product can be customized using the framework you have created with the preferences you selected.

-

You can examine the selections, criteria, components and operations you have chosen for the test configuration in the listview, as well as view the Merchandise and Labor figures.

-

The Review function lets you view a printable list of the all selections, criteria, options, components and operations you have chosen for the current configuration.

To deploy the product configuration:

-

Open the Product Configurator Maintenance program (Program List > Product Configurator > Setup).

-

Select the product configuration you want to deploy at the Configuration field.

-

Select Available to use at the Status field of the General tab.

This typically applies to salespeople and production planners.

A product can be configured to the customer's specifications using the Product Configurator Wizard (Program List > Product Configurator).

As a salesperson, you can typically access this wizard to customize products from within the Sales Order Entry or Quotations program. As a production planner, you can typically customize products from within the Estimates, Job Entry or Structures and Routings programs.

If you access the Product Configurator Wizard program via the Program List (i.e. not from within one of the programs indicated above) then you're using the wizard in the test mode. This is usually done to test a proposed configuration framework.

-

Open the Product Configurator Wizard.

-

Indicate the static information associated with the configuration that you want to customize such as the Configuration date, Configuration code and Quantity required fields.

-

Indicate the Component warehouse to use details.

This lets you override the default warehouse against the component.

This only applies if the Ask warehouse option is enabled in the Product Configurator Maintenance program.

-

Indicate the Configuration library details.

A configuration library enables you to store product configurations which are repeatedly used (i.e. instead of customizing the product every time a client requests it, you can save the configuration and select it the next time it is required).

This section is only applicable if the Retain configuration libraries option is enabled in the Product Configurator Maintenance program.

-

Select Next to proceed to the Selections window.

In this listview you can choose from the available pre-defined options.

The criteria already chosen for the product are listed in the Selections Review listview. You can select a data record to change the criterion value.

-

Once you have made all selections regarding the product, you can specify the details of the parent part if the configuration was set up to create a parent part in the Product Configurator Maintenance program.

-

Select Next to continue to the Components and Operations window where you can select the components and operations that must be included in the customized product. You can also view the Merchandise and Labor figures.

You can specify the quantity per component and add calculations for the component within the Range Component Selection window.

You can specify the run time per operation and view calculations for the operation within the Range Operation Selection window.

-

Depending on how the configuration was set up and your selections made, you may be prompted to specify the parent details.

-

The Complete window is the final step within the wizard.

If the Product Configurator Wizard was accessed from the Sales Order Entry or Quotations program, you can specify the price per component and possible line discounts.

If the Product Configurator Wizard was accessed from the Estimates, Job Entry or Structures and Routings program, you can change the default routing.

- The Review function lets you view a printable list of the all selections, criteria, options, components and operations you have chosen for the current configuration.

-

Once the you have completed all the steps in the wizard and you are in test mode, you will be prompted to print a comprehensive list of the selections, criteria, options, components and operations that have been chosen for the current configuration.

You've successfully customized a product according to the customer's specifications using a pre-defined configuration framework.

The configuration library lets you save a specific product configuration for re-use from within a program where a product can be customized. Re-using a configuration from the library saves time as you don't have to re-configure a product each time it is sold.

You can either save a configuration in the library from within a program once you have customized the product (e.g. from within Sales Order Entry) or at the end when testing the configuration using the Product Configurator Wizard.

The Retain configuration libraries option must be enabled against the configuration using the Product Configurator Maintenance program in order to save it the configuration in the library.

The configuration library lets you save a specific product configuration for re-use from within a program where a product can be customized.

Only the quantity, stock code, work center and sequence numbers you selected during configuration are stored in the library. Prices are not saved in the library, so that the library can be used in various modules.

For example:

You can create a configuration for a 2.2m green garden gate and save it in the library so that it can be selected from within the Quotations program.

The Retain configuration libraries option must be enabled against the configuration using the Product Configurator Maintenance program in order to save it the configuration in the library.

Follow these steps to save a configuration in the library:

-

Progress through the all the steps of the Product Configurator Wizard until you get to the last window, which is the Complete window.

A message box is displayed that prompts you to store the configuration in the library.

The message box will not be displayed if the Retain configuration libraries option is not enabled against the configuration (Product Configurator Maintenance).

-

Select Yes at the message box.

The Library Maintenance window is displayed.

-

Enter a unique code for the configuration, e.g. 2.2m green garden gate and a description.

-

Indicate the start and expiry dates at the Availability section.

-

Save the configuration.

Follow these steps to select a configuration from the library within a program (e.g. when customizing a product from within Sales Order Entry):

-

Access the Product Configurator Wizard.

-

Indicate the product you want to customize at the Configuration code field.

-

Select the Use a standard library check box to indicate that you are using a configuration from the library.

-

Select the code for the customized product at the Library code field, e.g. 2.2m green garden gate.

-

Progress through the all the steps of the Product Configurator Wizard to select the criteria, components and operations.

-

Complete the customization.

You are returned to the program from which you accessed the Product Configurator Wizard.

Follow these steps to select a configuration from the library within a program (e.g. when customizing a product from within Sales Order Entry):

-

Access the Product Configurator Wizard.

-

Indicate the product you want to customize at the Configuration code field.

-

Select the Use a standard library check box to indicate that you are using a configuration from the library.

-

Select the code for the customized product at the Library code field, e.g. 2.2m green garden gate.

-

Progress through the all the steps of the Product Configurator Wizard to select the criteria, components and operations.

-

Complete the customization.

You are returned to the program from which you accessed the Product Configurator Wizard.

Using

This step-by-step diagram indicates how the framework for a product configuration is created.

Typically a product engineer or estimator will create a template or model for a product configuration. Once created, the configuration can typically be used by a salesperson or production planner to design or customize a product according to the required specifications.

-

Open the Product Configurator Maintenance program (Program List > Product Configurator > Setup).

-

Indicate a name for the configuration that you want to create in the Configuration toolbar field.

-

Enter the static information at the General tab.

Step-by-step instructions

Step-by-step instructions

-

Indicate the Description, Comment, Engineer and Status.

-

Under the Availability drop-down, indicate the Start and Expiry dates for the configuration.

-

Under the Where-used drop-down, indicate the SYSPRO modules that can access the configuration.

A salesperson can access the Product Configurator Wizard from the following modules:

-

Sales Orders - via the Sales Order Entry program

-

Quotations - via the Quotations program

A production planner can access the Product Configurator Wizard from the following modules:

-

Quotations - via the Estimates program

-

Work in Progress - via the Job Entry program

-

Bill of Materials - via the Structures and Routings program

-

- You have to save the information before proceeding to the next tabs.

-

-

Select the Password function to create a password that must be supplied when the Product Configurator Wizard program is accessed from within a program.

-

At the Options tab, select configuration options, indicate details for parent parts and specify information for sales order documents.

Step-by-step instructions

Step-by-step instructions

-

Indicate if the quantity and warehouse can be specified at run time (i.e. when the product is customized) at the Ask quantity required and Ask warehouse fields.

-

Select whether alternate stock and warehouses an be specified at run time at the Allow alternate stock and Allow alternate warehouse fields.

-

Enable the comment fields to include selection criteria or user comments against a configuration.

-

Enable the Retain configuration libraries option to save customized product configurations in a library for repeated use.

-

At the Parent section you can indicate the types of parent parts that can be created and how they can be created.

This is not applicable if the parent Type is defined as None.

-

Indicate the various documents where you want to print a discount miscellaneous charge line for this specific configuration at the Sales orders section.

This section is only applicable if this configuration is to be used within the Sales Orders module (i.e. the Sales order option is selected against the Where-used section).

-

-

Indicate the default component warehouse, product class, Work in Progress and Bill of Materials details within the Defaults tab.

Step-by-step instructions

Step-by-step instructions

-

Indicate the default warehouse according to which you want to draw the stocked components against the Component warehouse field.

-

Indicate the default product class to assign to the stocked, non-stocked, labor and discount components or operations associated with this configuration.

-

Within the Work in progress section:

This only applies if the Type associated with the parent is defined as Stocked, Non-stocked or Both stocked & non-stocked.

-

Indicate the groups of jobs that you want to assign to this configuration using the Classification field.

-

Indicate the priority of the job by indicating a number from the range of 1 to 99 using the Job priority field.

1 indicates the lowest priority and 99 the highest priority.

-

Indicate the ledger account using the GL account field according to which the Work in Progress values must be posted to once a job is created.

-

There are various options that give you the ability to determine whether you want to include sequence checking on operations when creating a job, to confirm or place a job on hold by default.

This only applies if this configuration is used within the Work in Progress module (i.e. the Work in progress option is selected against the Where-used section).

-

-

In the Parent section, indicate the default product class that is used when generating a parent part.

This field only applies if the Use product class inventory defaults option at the Options tab is enabled .

-

Within the Bill of Materials section:

This section only applies if the configuration is used within the Bill of Materials module (i.e. the Bill of materials structures and routings option is selected against the Where-used section).

-

Indicate the default route to use when creating a bill of materials for the generated parent part for this configuration.

-

Indicate whether a salesperson has the ability to change the default routing for this configuration.

This only applies if the Alternate routings setup option is enabled (Setup Options > Preferences > Manufacturing > Bill of Materials).

-

-

-

Use the Selections and criteria tab to define the framework for the product configuration. The selections created here will be used as questions when customizing the product and the criteria against each selection serve as the answers.

Example

Example

The following aspects could be used when creating the selections for the framework of a Gate configuration:

-

Color

-

Dimensions (width and height)

-

Lock type

Within the color selection, the following particulars could be used when creating the criteria:

-

Black

-

Grey

Step-by-step instructions

Step-by-step instructions

-

To create a new selection:

-

Select the Add hyperlink against the first record in the listview.

This loads the Maintain/Add Selection window.

-

Indicate all relevant information and whether this is a Mandatory or Optional selection (i.e. whether this option must be selected in the Product Configurator Wizard).

-

Save the selection.

-

Once the selection is saved, you can select the hyperlinks to copy and edit the selection.

-

Select the Play hyperlink within the Multimedia column to load the multimedia (i.e. images, videos and documents) associated with a selection.

-

-

To add criteria for a single selection:

-

Select the Add hyperlink for the selection.

This loads the Maintain/Add Criteria window.

-

Indicate the relevant information for the criterion.

-

-

-

Use the Options and components tab to define the options associated with the configuration.

Step-by-step instructions

Step-by-step instructions

-

To add an option for a configuration:

-

Select the Add hyperlink against the first record (i.e. configuration) to associate an option for existing selections and criteria.

This loads the Maintain/Add Option window.

-

Indicate the name you want to associate with the option at the Description field.

-

Indicate whether you want to add an component or a component at the Option type field.

-

Indicate whether you require to define minimum or maximum number of components or operations by selecting the Ranges to be used in this option check box.

This enables the Component quantity section.

-

Indicate the information surrounding the offset that can be defined according to operation or the number of days by using the Component offset section.

-

Indicate the current and new sequence for the option under the Sequence section.

Exercise caution when changing the option's sequence as this as an effect on dependency links.

-

Save the component or operation.

-

-

To associate a component or operation with an option:

-

Select the Add hyperlink for the newly added option.

This loads the Maintain Operation or Maintain/Add Component window.

The window that is displayed depends on whether you selected List of operations or List of components when you created this option within the Maintain/Add Option window.

-

Indicate the relevant information and save your changes once you've defined the component or option.

-

You can also add calculations for operations and components.

-

-

To create a link between various criteria and the option that you've just added:

-

Select the hyperlink associated with the name of the component or option as accessible via the Configuration column.

A context-sensitive menu is displayed.

-

Select the Dependencies option.

-

Select the Selection criteria option to create links between the criteria (i.e. options) associated with the selections (i.e. questions) and the operation or component.

This loads the Dependent Selection Criteria window.

This is applicable to both components and operations.

-

Select the Components option to create links between one component with one or more other components.

You have the ability to define the relevant calculations for this configuration via the window that is loaded once you've selected the browse icon alongside the Components field.

This loads the Configurator Component Dependencies window.

This is only applicable to components.

-

-

-

You've successfully created a product configuration.

You can test the configuration using the Product Configurator Wizard program (Program List > Product Configurator) to ensure that the product can be customized using the framework and preferences you created.

-

Once tested, you can deploy the product configuration by selecting Available to use at the Status field of the General tab within the Product Configurator Maintenance program.

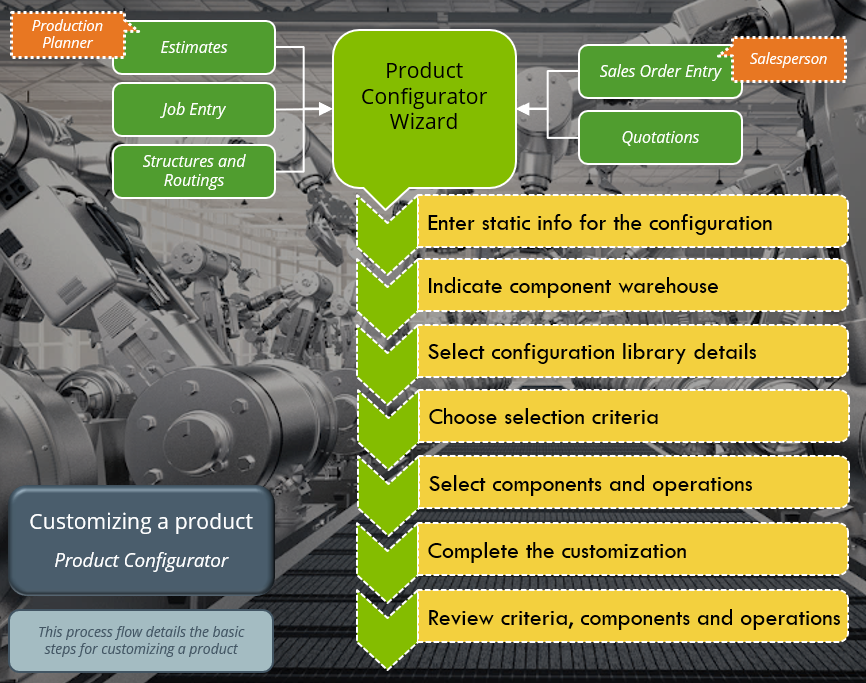

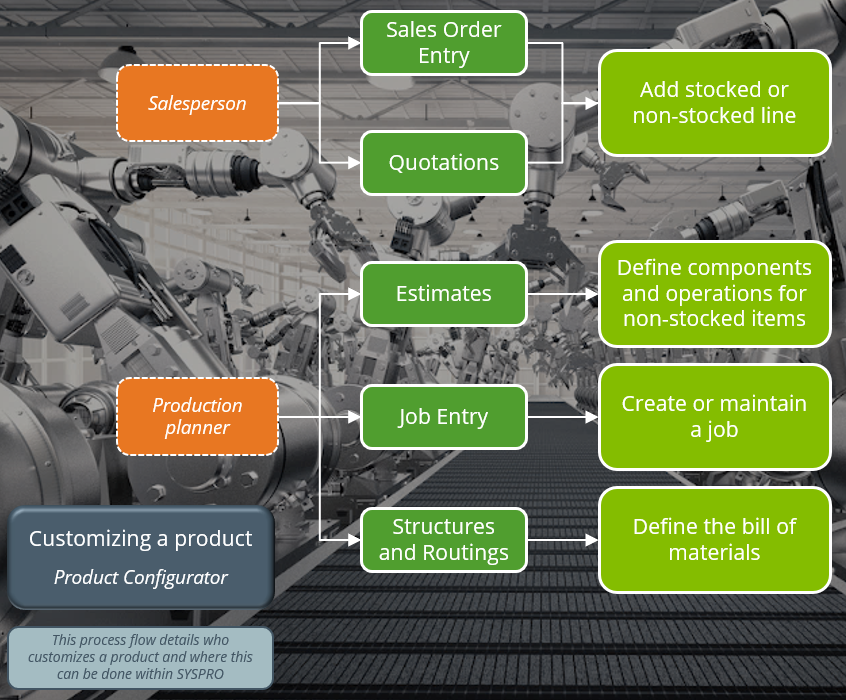

This step-by-step diagram displays how a sales person or production planner can customize a product using a product configuration framework.

A product can be configured to the customer's specifications using the Product Configurator Wizard (Program List > Product Configurator).

As a salesperson, you can typically access this wizard to customize products from within the Sales Order Entry or Quotations program. As a production planner, you can typically customize products from within the Estimates, Job Entry or Structures and Routings programs.

If you access the Product Configurator Wizard program via the Program List (i.e. not from within one of the programs indicated above) then you're using the wizard in the test mode. This is usually done to test a proposed configuration framework.

-

Open the Product Configurator Wizard.

-

Indicate the static information associated with the configuration that you want to customize such as the Configuration date, Configuration code and Quantity required fields.

-

Indicate the Component warehouse to use details.

This lets you override the default warehouse against the component.

This only applies if the Ask warehouse option is enabled in the Product Configurator Maintenance program.

-

Indicate the Configuration library details.

A configuration library enables you to store product configurations which are repeatedly used (i.e. instead of customizing the product every time a client requests it, you can save the configuration and select it the next time it is required).

This section is only applicable if the Retain configuration libraries option is enabled in the Product Configurator Maintenance program.

-

Select Next to proceed to the Selections window.

In this listview you can choose from the available pre-defined options.

The criteria already chosen for the product are listed in the Selections Review listview. You can select a data record to change the criterion value.

-

Once you have made all selections regarding the product, you can specify the details of the parent part if the configuration was set up to create a parent part in the Product Configurator Maintenance program.

-

Select Next to continue to the Components and Operations window where you can select the components and operations that must be included in the customized product. You can also view the Merchandise and Labor figures.

You can specify the quantity per component and add calculations for the component within the Range Component Selection window.

You can specify the run time per operation and view calculations for the operation within the Range Operation Selection window.

-

Depending on how the configuration was set up and your selections made, you may be prompted to specify the parent details.

-

The Complete window is the final step within the wizard.

If the Product Configurator Wizard was accessed from the Sales Order Entry or Quotations program, you can specify the price per component and possible line discounts.

If the Product Configurator Wizard was accessed from the Estimates, Job Entry or Structures and Routings program, you can change the default routing.

- The Review function lets you view a printable list of the all selections, criteria, options, components and operations you have chosen for the current configuration.

-

Once the you have completed all the steps in the wizard and you are in test mode, you will be prompted to print a comprehensive list of the selections, criteria, options, components and operations that have been chosen for the current configuration.

You've successfully customized a product according to the customer's specifications using a pre-defined configuration framework.

The following table indicates the possible status codes for a product configuration:

| Status | Description |

|---|---|

|

1 - Available to use |

The product configuration has been deployed and can be selected within the Product Configurator Wizard program. |

|

2 - Under development |

The product configuration is still in development or is undergoing maintenance and can't be selected within the Product Configurator Wizard program. |

The following indicates areas in the product that may be affected by implementing this feature:

Program List > Product Configurator > Setup

This program is used to update the costs and prices for any non-stocked components used in a product configuration.

This program is only available in the SYSPRO Desktop version.

Program List > Product Configurator > Setup

This program is used to replace one component with another in one or more product configurations.

This program is only available in the SYSPRO Desktop version.

Program List > Product Configurator > Setup

This program is used to create and maintain a configuration structure for a product that is typically manufactured-to-order, assembled-to-order or sold in many different configurations.

Program List > Product Configurator

This program is used to remove expired or outdated product configurations and configuration libraries.

This program is only available in the SYSPRO Desktop version.

Program List > Product Configurator

This program is used by salespeople or production planners to create a customized product according to specifications. This program can also be used by product experts, engineers or estimators to test a configuration that they created.

This program is automatically displayed from within the Product Configurator Wizard when a job is created with a parent. A job can be created when a product is customized from within the Sales Order Entry, Quotations or Job Entry programs.

This program lets you define the job details when a job is created by the Product Configurator Wizard.

This program is displayed when selecting the Review changes option within the Product Configurator Wizard after completing changes to a configuration that was modified or re-configured.

This program is used to review and update the components and operations in an existing bill of materials, estimate or job for a product configuration.

Program List > Product Configurator > Reports

This program is used to generate a list of product configurations that were created using the Product Configurator Maintenance program.

This program is displayed when selecting the Query option of a component listed in the Options and Components pane within the Product Configurator Maintenance program.

This program is used to view the components and operations for an existing configuration.

Program List > Product Configurator > Browse

This program is used to view product configurations details, to copy configurations and maintain configuration libraries.

Accessible from the Library code field of the Quotations Query program (Quotation Detail Values pane) or Sales Order Query program (S/O Line Information pane).

This program is used to view details of operations and components for the configuration library associated with a specific quotation or sales order line.

Accessible from the Browse icon at the Sequence field of the Options and Components tab within the Product Configurator Maintenance program.

This program is used to browse on options for components and operations.

Accessible from the Browse icon at the Sequence field of the Selections and Criteria tab within the Product Configurator Maintenance program.

This program is used to browse selection criteria.

The Product Configurator Setup business object lets you add, change and delete product codes for a product configurator.

The Product Configurator Calculations business object lets you maintain calculations of the product configurator. Calculations can be added, copied, deleted, and updated.

The Product Config Replace Where Used business object is used by the Configurator Replace Component Where Used program and lets you globally replace one component with another component in one or more configurations.

The Product Configurator Dependencies business object lets you maintain product configurator dependencies. Dependants (selection criteria and components) can be added and deleted.

The Product Configurator Invalid Selection business object lets you add and delete invalid product configurator selections.

The Product Configurator Criteria Maintenance business object lets you add and delete product configurator criteria.

The Product Configurator Operation Maintenance business object lets you add and delete product configurator operations.

The Product Configurator Material Maintenance business object lets you add and delete product configurator materials.

The Product Configurator Options Maintenance business object lets you add and delete product configurator options.

The Product Configurator Selection Maintenance business object lets you add and delete product configurator selections.

The Product Configurator Options business object lets you process the operations and components of a product configuration.

The Product Configurator Finish Details business object lets you create the sales order, bill of material, estimate, quotation and job for a product that was customized using a product configuration.

The Product Configurator business object initializes the configuration process and calls the subsequent business objects.

The Product Configurator Parent Details business object processes the parent details of the customized product.

The Product Configurator Selection Criteria business object processes the selection criteria of the customized product.

The Product Config List Configurations business object lets you query a list of product configurations.

The Product Configurator Progress Query business object lets you query the following for a configuration:

-

Selections

-

Criteria

-

Comments

-

Parent information

-

Options

-

Components

-

Operations

Copyright © 2025 SYSPRO PTY Ltd.