You use this program to replace a component stock code with a valid substitute component.

| Field | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Process Replacement |

Replaces the existing component with the new valid substitute component with immediate effect. If the substitute component already exists on a bill of materials and it has the same sequence number as the component to replace, then you are given the option of skipping the replacement or continuing to accumulate quantities.

|

||||||||

| Parent stock code selection | Indicate the parent stock code(s) in which the component must be replaced. | ||||||||

| Parent route selection | If you enabled the setup option Alternate routings (Bill of Materials Setup) then you can select the route of the parent in which the component must be replaced. | ||||||||

| Component to replace options | |||||||||

| Component to replace | Indicate the existing component that must be replaced. | ||||||||

| Component to replace description | Indicates the description of the component you selected to replace. | ||||||||

| Component to replace ECC consumption |

Indicate the existing component's revision/release if the Component to replace is ECC controlled. This defaults to Specified and cannot be changed when the Stock control level is set to Stock code (Bill of Materials Setup).

|

||||||||

| Component to replace revision | Indicate the specific revision of the component you want to replace. This only applies when Component to replace ECC consumption is set to Specified. | ||||||||

| Component to replace release | Indicate the specific release of the component you want to replace. This only applies when Component to replace ECC consumption is set to Specified. | ||||||||

| Where used | Uses the BOM Browse on Component Where-used program to view all parent parts to which the component has been assigned. | ||||||||

| Quantity on hand |

This is the current quantity on hand of the component to replace. |

||||||||

| Quantity on order |

This is the current quantity on order for the component to replace. |

||||||||

| Quantity allocated |

This is the current quantity allocated for the component to replace. |

||||||||

| WIP allocated |

This is the current work in progress quantity allocated for the component to replace. |

||||||||

| Replacement component options | |||||||||

| Replacement component | Indicate the component that will replace the current component against the bill. | ||||||||

| Replacement component description | Indicates the description of the substitute component. | ||||||||

| Replacement component ECC consumption |

This determines the revision/release to use when the substituted component is issued to the job if the component is ECC controlled (Stock Codes). This defaults to Specified and cannot be changed when the Stock control level is set to Stock code (Bill of Materials Setup).

|

||||||||

| Component to replace revision | Indicate the specific revision of the substitute component if the component is ECC controlled and the Replacement component ECC consumption is set to Specified. | ||||||||

| Component to replace release | Indicate the specific release of the substitute component if the component is ECC controlled and the Replacement component ECC consumption is Specified, | ||||||||

| Replacement options | |||||||||

| Update on/off dates | If you enabled the Structure on/of dates option (Bill of Materials Setup) then you can indicate when the new component should override the existing component (i.e. the structure on and off dates for the current and the replacement components). | ||||||||

| Effective date | Enter a date in the future when the structure on date

must be set against the replacement component. The structure

off date for the current component is set to 1 day before the

date you enter here. When you define a component that already exists on file and you define an effective date. The request change is ignored if you define a date for a component that already exists on file. At the end of the process the system notifies of the number of components that were not updated. |

||||||||

| Quantity per multiplier | Enter the value by which the quantity per against the current component must be multiplied to determine the quantify per for the replacement component. This defaults to 1. | ||||||||

| Sequence number selection | If a component exists more than once on a Bill of

Material, then you use this option to define whether all

occurrences or only a single occurrence of the component must

be replaced.

|

||||||||

| Sequence number | Indicate the sequence number of the single component you want to replace in the bill. | ||||||||

| Copy multimedia | Copies multimedia objects defined against the existing

component to the substitute component. The existing multimedia objects against the substitute component are replaced. |

||||||||

| Copy custom forms | Copies custom forms defined against the existing

component to the substitute component. The existing custom form data against the substitute component is replaced. |

-

The replacement component cannot be a:

- Notional part

- Planning bill

- Kit type 'K' or 'S'

- Co-product (when its parent is a notional part)

-

The replacement component is ignored if it is a:

- Co-product (when its parent is a notional part)

- Phantom part (if its parent is a kit type item).

-

The Warehouse to use defined against the replacement component must be the same as the warehouse to use defined against the current component.

Example:

When the parent component relationship is being configured, you can specify the warehouse that must be used (Structures and Routings).

Assume that parent stock code B100 has components B111, B112 and B113 and the parent component relationship of B100 to B111 has the Warehouse to use set to RM. You run out stock of component B111 and want to substitute B999 for B111. However, B999 is not stored in warehouse RM. The replace component where-used process (to replace B111 with B999) will fail, because the entered warehouse value is not changed; only the stock code.

-

You can replace any components for ECC-controlled items as long as there is an engineering change order in place for the parent item and you have enabled the Enable BOM Maintenance function (ECC Change Orders).

-

When the Parent traceable if component traceable setup option is enabled (Lot Traceability Setup) you can replace a non-traceable component with a traceable component providing:

-

Parent stock code selection is set to Single

and

-

the parent item is traceable

When Parent stock code selection is set to All, Range or List and the Parent traceable if component traceable setup option is enabled (Lot Traceability Setup) you can only replace a lot traceable component with another lot traceable component.

-

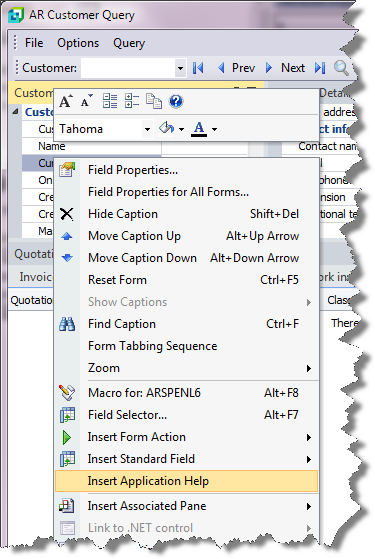

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.