You use this program to initiate the creation of engineering change orders and to track existing engineering change orders in the workflow.

- Toolbar and menu

- ECO Information

- Description

- Notepad

- Affected Items

- On Hold

- Actions

- Activity History

- Notes and warnings

| Field | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| New |

Select this to initiate the creation of an engineering change order. You can restrict the initiation of engineering change orders by denying engineering users the authority to access the initial engineering change order status. |

||||||||

| Save | Select this to save the details you entered or changed. | ||||||||

| ECO number |

Indicate the engineering change order you want to track in the workflow. Within the browse function you can use the Include menu to selectively filter engineering change orders according to ECO Status (i.e. New, In progress, Held, Complete and Cancelled). |

||||||||

| Functions | |||||||||

| Change Status | Select this to set the ECO system status to complete.

This option is only enabled when the system detects that the ECO system status is out of sync with the ECO itself. In this case, the ECO is actually complete, but its status is still recorded as 'in progress.' When you select this option, you are prompted to confirm that you want to set the ECO status to complete. |

||||||||

| Hold Stock Codes |

Select this to apply a number of locks against stock codes listed in the ECO. Each hold can be applied to all revisons/releases or only to the current revision/release.

|

||||||||

| Release Stock Codes | Select this to selectively release stock codes previously placed on hold for this ECO. | ||||||||

| Enable BOM Maintenance | Select this to use the Structures and Routings program to maintain the

structure of the ECC item. Note that any changes you make are not made to the original Bill of Materials until you select the Apply BOM Changes option. If you made changes to the BOM, then when you select the Apply BOM Changes option, the original BOM is archived and the changed BOM now becomes the current BOM for the ECC item. |

||||||||

| Apply BOM Changes | Select this to apply the changes you made to the

structure using the Structures and Routings program. If you enabled the option: Allow cosmetic changes for ECO (Bill of Materials Setup) and you have not made any major changes, then the message: Save cosmetic changes without changing the revision/reklease for the stock code? is displayed. If you select Yes, then the revision/release remains unchanged for the item. If you select No, then the item is saved against a new revision/release. The ECC Change ECO Status program is loaded, to perform the status changes for the engineering change order. |

||||||||

| Abandon BOM Changes | Select this to abandon all changes to the structure and routing for the affected items. | ||||||||

| Unset ECC Control | Select this to unset ECC control for all affected items. | ||||||||

| ECO Actions | Select this to use the ECC Change Order Actions program to action events that have been activated against an engineering change order. |

| Field | Description |

|---|---|

| ECO Information | |

| ECO number | This is the change order you are currently maintaining. |

| Status | This indicates the status of the ECO. When adding an ECO, this defaults to the Initial ECO Status. The status of an ECO is automatically moved to the next status when:

|

| Status description | This indicates the description of the current status of the ECO. |

| Since | This indicates the date when the engineering change order was initiated. |

| ECO system status | This indicates the current system status of the engineering change order. |

| ECO originator | This indicates the ECO operator who originally created the ECO. |

| Responsible user | This indicates the responsible user for the

ECO. This defaults to the Default ECC user defined in the Bill of Materials Setup program when you add a new item. |

| Expected available date | This indicates the projected date for the finalization of the engineering change. |

| Field | Description |

|---|---|

| Descriptions | |

| Short description | Indicate a short description for the ECO. |

| Description of change | Enter a more detailed description for the ECO. |

| Reason for change | Indicate the reason for affecting the change. |

This pane enables you to add free format notes to the ECO.

| Field | Description |

|---|---|

| Save | Select this to save the text entered in the Notepad pane. |

| Add Lines | Select this to add a note line. The text for the note

line is entered in the Notepad

pane. You must select this option to create the note, as a note is only saved when it has a description. |

| Notes Description | |

| Description | This is the description of the note. This defaults to the first line added in the Notepad pane, but can be changed. |

| Operator | This indicates the name of the operator who initially entered the note. |

| Last change | This indicates the date on which the note was last changed. |

| Entry | This indicates the note entry number. |

| Editable for other operators |

Select this to allow subsequent users to add or amend the original notations captured. You can delete the line when this option is enabled. |

| Notepad | Enter free format text for the note. |

The options on this tab enable you to add stock codes which are affected by the engineering change.

At least one product must be specified before an ECO can be moved from the system status of New to In Progress.

Affected items can be removed from the ECO while it is in progress by selecting the item in the Affected Items listview, using the Delete key and then saving the ECO.

![[Note]](images/note.png)

|

|

|

Although there is an option to add the new revision/release for the item, if revisions and releases are defined as being numeric and automatic (Set Key Information) then these fields can be left blank and the current revision/release will be rolled up when the ECO is completed. |

|

| Field | Description |

|---|---|

| Affected Items | |

| Where-used | Select this to use the Stock Code Where-used Query program to identify possible candidates. |

| By Stock Code | Select this to use the ECC Change Order Browse by Stock Code program to view the ECO numbers related to the selected stock item. |

| Structure and Routings | Select this to use the Structures and Routings program to maintain the structure and routings for the currently highlighted line. |

| Set all on hold | Select this to prevent all affected stock items listed

from being maintained using the Stock Codes program and from

maintaining warehouses for the stock items using the Inventory Warehouse Maintenance for Stock Code

program. This enables you to put stock code maintenance on hold while the stock codes are affected items within an active ECO. This is only available when more than one affected item is listed. When only one item is listed, you enable the Hold stock maintenance checkbox in the listview. |

| Set all released | Select this to re-allow maintenance on all stock items

listed in the listview. This is only available when more than one affected item is listed. When only one item is listed, you deselect the Hold stock maintenance checkbox in the listview. |

| Stock code | Indicate the code of the stock item affected by the engineering change. |

| Description | This displays the description of the Stock code. |

| New Revision | Indicate the new revision number for the stock code for the change order. |

| New Release | Indicate the new release number for the stock code for the change order. |

| Current Revision | This indicates the current revision number for the stock item. |

| Current Release | This indicates the current release number for the stock item. |

| Hold stock maintenance | Enable this to prevent the stock code from being

maintained using the Stock Codes program and from maintaining

warehouses for the stock item using the Inventory Warehouse Maintenance for Stock Code

program. A tick in this column means that stock code maintenance is on hold while the ECO is in process. Therefore, operators working on the change order will need to be informed of any changes made to the stock code (e.g. changes to the EBQ) and problems in identifying changes brought about by the ECO on completion are prevented. You can set stock maintenance on hold/released for an affected item at any point within an active ECO. The hold is automatically removed when an ECO is set to complete or cancelled. |

This listview displays all jobs, sales orders and purchase orders which are on hold for the ECO.

This listview displays all events that have been fired for the ECO, including the date and time the event was fired.

When the ECO is moved from New to In Progress, the current revisions/releases of the BOMs and routings for all products listed on the ECO and for all routes flagged as being subject to ECC are copied to separate tables.

All maintenance of BOMs and routings for ECC-controlled products is performed against these tables.

-

You cannot enable Structure and Routing maintenance for the same stock code on more than one ECO.

-

Two operators cannot maintain an ECO at the same time. If an operator is maintaining an ECO, a second operator will not have access to that ECO until the first operator has released the resource lock.

-

Enabling the option: Allow cosmetic changes for ECO (Bill of Materials Setup) determines whether you are prompted to change the revision/release of affected items.

If you select to change the release, then the BOM is updated without changing the revision.

-

For automatic control, components added and deleted are considered significant changes, as are changes to the following fields:

-

Revision (Component)

-

Release (Component)

-

Unit of Measure

-

Quantity per

-

Fixed quantity flag

-

Parent per fixed quantity

-

Structure on date

-

Structure off date

-

Include from job number

-

Include to job number

-

Scrap percentage

-

Scrap quantity

-

Warehouse to use

If a structure or routing is not found when checking for cosmetic changes, the item is assumed to be a component and its revision/release is changed.

When saving cosmetic changes for an affected parent item, if a component against the BOM of the parent is also an affected item, then this component revision/release is not applied to the parent, as this constitutes a major change. This applies even if the component revision/release is changed at the time of applying BOM changes.

-

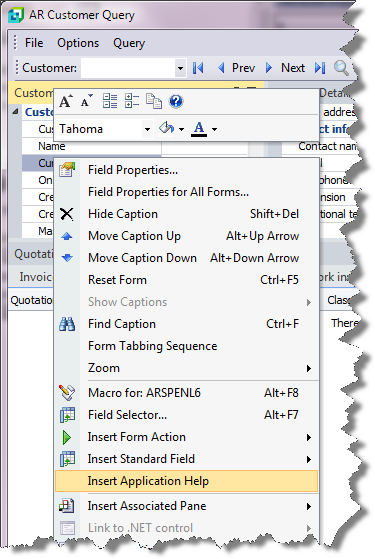

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.