You use this program to create and maintain your work centers.

- Toolbar and menu

- Work Center Details - Internal

- Work Center Details - Subcontract

- Work Center GL Integration

- Work Center Rates

- Notes and warnings

| Field | Description |

|---|---|

| Work Center | Indicate the code of the work center you want to maintain. |

| Play | Select this to use the Multimedia program to view multimedia objects defined against the |

| Edit | Select this to use the Multimedia program to define multimedia objects against the |

| Cost center | This indicates the cost center to which the work center

belongs. When you change the Cost center, the following message is displayed: "Please note that the Cost Center values will override the equivalent Work center values. Do you want to proceed?" If you select OK, then Units of measure, Run time calculation method, Product class for billings, Overtime capacity fields, GL Integration and Work Center Rates are copied from the Cost center you enter in this field, to the Work center. The following fields retain the original values of the existing Work center: Queue time, Number of work operators, Number of units, Unit description, Time per unit/day, Normal capacity per unit/day and Utilization percentage. |

| Capacity Calendar | Select this to use the Capacity Calendar Maintenance program to define daily capacity records for individual work centers. |

The fields in this pane enable you to define default information for an internal work center.

| Field | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| General Information | Indicates the work center currently being maintained. | ||||||||

| Work center | Indicates the work center currently being maintained. | ||||||||

| Description | Indicate a description for the work center. The description is printed on reports and can be used to verify that you have entered the correct work center. |

||||||||

| Cell id | Indicates the work center's cell id that is used within the Advanced Planning & Scheduling system. | ||||||||

| Cost center | Indicates the cost center code for the work center you are currently maintaining. | ||||||||

| Cost center description | Indicates the Cost center description for the work center. | ||||||||

| Cost center type - Internal | Indicates that the cost center's rates must be derived internally and that the work is performed on site. | ||||||||

| Run time calculation method | The option you select here determines how the run time

is calculated. For Rate and Block time methods, you enter the Quantity and Time taken for the operation in the Structures and Routings program. The Unit run time is then calculated according to the quantity to manufacture.

|

||||||||

| Queue time (days) | Indicate the amount of time a job is planned to wait at

a work center before any work is performed. The entry made here is added to the elapsed time held against an operation to calculate the full operation lead time. |

||||||||

| Number of work operators | Indicate the number of operators available at the work

center. This cannot be zero. The entry is used for documentary purposes only. |

||||||||

| Use employee rates | Select this to use the rates defined against the

employee instead of the rates held against the work center.

The Work center overhead recovery rates are still applied. This is used in actual costing. |

||||||||

| Units of measure | If you made an entry at the option: Default description of time units (Bill of Materials Setup then this is displayed at the Time and Capacity fields. | ||||||||

| Time | Indicate the time unit of measure for the work

center. The work center overhead recovery rates are still applied. |

||||||||

| Capacity | Indicate the capacity unit of measure for the work

center. The value held against the cost center is displayed here by default, but can be overridden. |

||||||||

| Conversion factor | Typically this conversion factor is applied when the

operation's times are posted in, for example, seconds or

minutes, but you want the overall capacity of the work center

to be viewed as hours. For example: You have an operation where the time is posted as minutes. You set the conversion factor to 0.0167 to convert these times to hours. Each item takes 12 minutes to complete, so converted to hours for capacity would give you 0.2 hours (12 / 60) of capacity per unit. Other less common capacity measures are shifts (e.g. 10 hours per shift) and even setups of days of capacity. |

||||||||

| Manual override | Enable this to override the factor calculated by the system and enter the factor you require manually. | ||||||||

| Factor | Indicate the factor according to which the Time unit of measure is converted into the capacity required, taking utilization into account. | ||||||||

| Productive units | |||||||||

| Number of units | Indicate the number of productive units for the work

center. This is the lowest common denominator in which the productive unit capacity of a work center is grouped within a factory. |

||||||||

| Unit description | Indicate the description for the units entered in the previous field. | ||||||||

| Time per unit/day | Indicate the time per productive unit per day. The entry made here is used in the capacity conversion factor calculation. | ||||||||

| Normal capacity per unit/day | Indicate the normal capacity per unit per day. The entry made here is used in the capacity conversion calculation and to calculate the elapsed time. | ||||||||

| Utilization percentage | Indicate the percentage of utilization to be used in the capacity conversion factor calculation. | ||||||||

| Part Billings | |||||||||

| Product class for billings | Assign a product class to all operations processed

within this work center. This is used only by the Part Billings program where you can set a preference for detail operation lines to be inserted at the time of creating a sales orders. If left blank, then operation details are grouped according to the default product class specified in the Part Billings program. |

||||||||

| Labor service charge |

Enter the default labor service charge code for this work center when using the Part Billings program to process a labor service charge. If you do not define a default code in this field, then the code entered at the Default labor service charge field (Work in Progress Setup) is used by the Part Billings program. This field is disabled if the option: Labor service charge is set to Not Required (Work in Progress Setup). Service charge codes are maintained using the Service Charges program. |

||||||||

| Overtime capacity | Indicate the percentage of overload permitted for the work center. This is used only within the Forward Finite Scheduling program. | ||||||||

| Use overtime | Enable this to allow overtime for the work center. | ||||||||

| Percentage | Indicate the percentage of overload permitted for the work center. |

The fields in this pane enable you to define default information for a subcontract work center.

| Field | Description |

|---|---|

| Work Center Details | This indicates the work center you are currently maintaining. |

| Work center | This indicates the work center you are currently maintaining. |

| Description | Indicate a description for the work center. The description is printed on reports and can be used to verify that you have entered the correct work center. |

| Cell id | This indicates the work center's cell id that is used within the Advanced Planning & Scheduling system. |

| Cost center | This indicates the cost center code for the work center you are currently maintaining. |

| Cost center description | This indicates the description for the cost center code for the work center you are currently maintaining. |

| Cost center type - Subcontract | This indicates that the cost center's rates must be derived from an external supplier. |

| Supplier | Indicate the default supplier that will be used by the work centers allocated to the cost center. |

| Supplier name | This indicates the name of the supplier (Suppliers). |

| Planner | Indicate the default planner that will be used by the work centers allocated to the cost center. |

| Planner name | This indicates the name of the planner (Browse on Planners). |

| Buyer | Indicate the default buyer the work centers allocated to the cost center will use. |

| Buyer name | This indicates the name of the Buyer. |

| Product class for billings | Assign a product class to all operations processed within this cost center. |

| Product class description | Indicates the description of the Product class for billings. |

The fields in this pane enable you to assign the ledger codes to which you want to apportion productive and non-productive costs.

![[Note]](images/note.png)

|

|

|

|

| Field | Description |

|---|---|

| Productive time ledger codes |

Assign the ledger codes to which you want to apportion productive costs. Ledger codes can be entered for each of the following:

|

| Non-productive time ledger codes |

Assign the ledger codes to which you want to apportion non-productive costs. Ledger codes can be entered for each of the following:

|

| Ledger code | Indicate the General Ledger code to which subcontract

costs must be posted. This field is only available for subcontract work centers. |

You use the Rates table to define the default rates applicable to a Work center for an internal cost center.

The rates currently defined are displayed in the table.

![[Note]](images/note.png)

|

|

|

You cannot access the Rates table for a Work center for a Subcontract cost center. |

|

| Field | Description |

|---|---|

| Rate | This indicates the code for the rate. |

| Set-up | Enter the set up rate for one unit of measure for the operation. |

| Start up | Enter the start up rate for one unit of measure for the operation. |

| Run | Enter the run rate for one unit of measure for the operation. |

| Teardown | Enter the tear down rate for one unit of measure for the operation. |

| Fixed o/h | Enter the fixed overhead rate for one unit of measure for the operation. |

| Variable o/h | Enter the variable overhead rate for one unit of measure for the operation. |

These rates are used to cost labor and overheads for an operation that takes place in the work center. The Cost Implosion program uses these rates to establish the labor and overhead content of the standard cost of sub-assemblies and finished products.

| Field | Description |

|---|---|

| Rate | This indicates the rate indicator number currently being maintained. |

| Set-up | Indicate the rate at which to cost the labor used when a specific machine, line or work center converts from production of one item to another. Typically, no usable items are produced during the set-up period. |

| Startup | Indicate the rate at which to cost the labor used when a specific machine, line or work center is gradually brought up to full production speed while producing good product. |

| Run | Indicate the rate at which to cost the labor used to produce items at full production speed. |

| Teardown | Indicate the rate at which to cost the labor used to remove setup from a machine or facility. |

| Fixed o/h | Indicate the fixed overhead rate.

This is the rate at which to cost expenditures that do not vary with production (e.g. rent apportioned to the work or cost center). |

| Variable o/h | Indicate the variable overhead rate.

This is the rate at which to cost the expenditures that vary with production (e.g. electricity apportioned to the work or cost center). |

Electronic Signatures provide security access, transaction logging and event triggering. This enables you to increase control over your system changes.

Access to the following eSignature transactions within this program can be restricted at Operator, Group, Role or Company level. You configure this using the eSignature Setup program.

| eSignature Transaction | Description |

|---|---|

| BOM Work center added |

Controls access to the New Work Center and Add functions in the Work Centers and Browse on Work Centers programs. |

| BOM Work center changed |

Controls access to the maintenance of work centers in the Work Centers and Browse on Work Centers programs. |

| BOM Work center deleted |

Controls access to the Delete function in the Work Centers and Browse on Work Centers programs. |

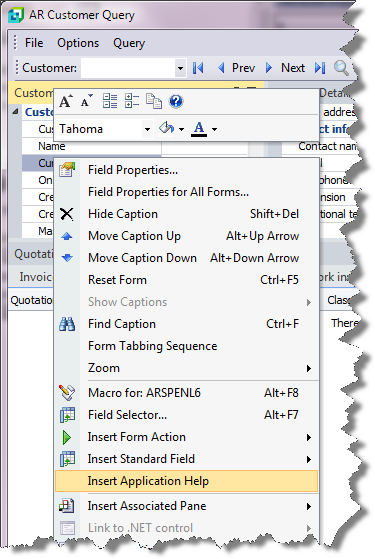

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.