Marshalling

The WMS Marshalling: Pre-dispatch Prepare feature enhances warehousing capabilities by providing businesses with streamlined staging and packing of sales, enabling consolidation of multiple sales orders into one shipment, with the ability to generate manifests and flexible printing of outer labels based on packaging constraints.

Exploring

-

increased customer satisfaction as the correct goods are dispatched and fewer picks missed

-

reduced costs as orders are consolidated into fewer dispatches to reduce shipping/carrier overheads

-

engagement with ESG (environment, social and governance) goals by ensuring the correct packaging is used

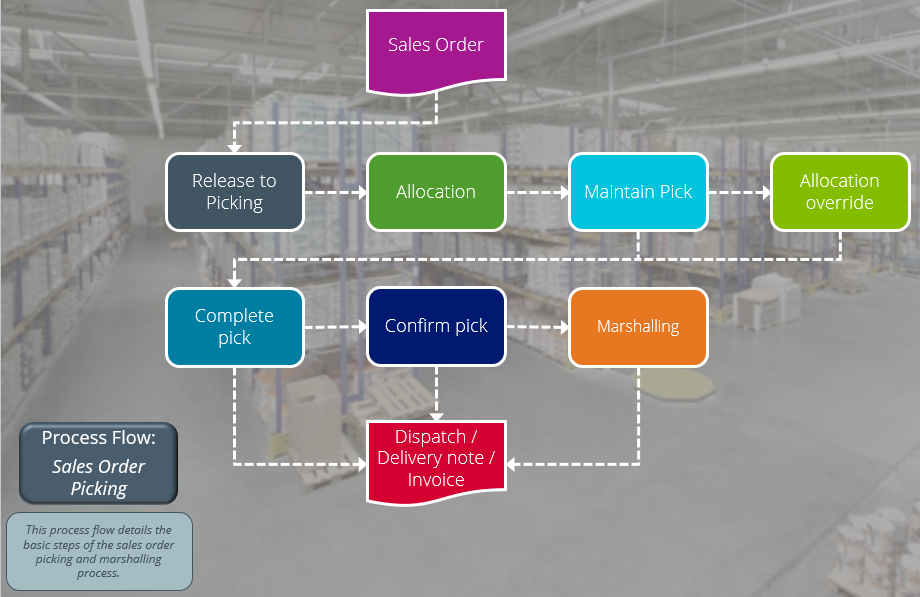

The Sales Order Picking functionality within our Warehouse Management system was extended to include a pick confirmation and marshalling process.

The WMS Marshalling: Pre-dispatch Prepare process is used within the pack and ship area of the warehouse and includes the functionality to separate and consolidate picks while packaging the goods in preparation for dispatch, thereby verifying the quality of stock items and completeness of the pick.

The Order Picking confirmation process is used ensure that the correct stock items have been picked and that completed picks have arrived at their destination. It also ensures that the lot and serial numbers that have been captured during the picking process correspond with those on the picked items.

The programs related to this feature are accessed from the Program List of the SYSPRO menu:

- Program List > Warehouse Management > Picking

This is the warehouse optionally configured to store variances arising during picking or cycle counting.

The quantity that is short is moved to the lost and found warehouse at the time the pick line or entire pick is completed and set to C - Picked.

Items can be retrieved from the L&F warehouse during cycle counting using the Lost and Found Warehouse Review program.

The lost and found warehouse is only enabled if a warehouse is defined at the Lost and found warehouse setup option and Process to lost and found warehouse is selected at the Accounting for shortages option (Warehouse Maintenance) .

This is a Warehouse Management process where picks are consolidated, split, and packaged in preparation for dispatch.

This adds efficiency in the dispatch process by reducing costs when consolidating multiple orders fora single customer and ensuring that picked items are packaged correctly.

An outer is a container, such as a box, package, bag, etc. in which the picked stock items are packed to prepare them for dispatch.

This is a Warehouse Management process that is implemented within a company to ensure that the correct stock items (with the correct lot and serial numbers) have been picked, to verify quality of picked items prior to dispatch and to confirm that completed picks have arrived at their destination.

This is a bin transfer movement type that applies when you complete a pick. The quantity picked is transferred from the sales order bin to the destination bin.

For Order Picking, the destination bin of the generated pick can be selected within the SO Picking Options program.

A sales order may be set aside to create a pick at a later stage. These sales orders have not yet allocated stock.

You use the Pick Review program to select these sales orders (at a later stage) to create a pick.

This is the process of finding and extracting products from a warehouse bin to fulfill customer sales orders.

This denotes a scenario where the original quantity for a sales order cannot be satisfied with the actual quantity found in the bin, resulting in an outstanding quantity for the sales order line.

If you decide to complete this pick while there is outstanding quantity, the outstanding quantity is placed on back order.

Within SYSPRO, a warehouse represents an actual warehouse containing your inventory items (i.e. a physical warehouse) or a grouping of your inventory according to specific characteristics of the item (i.e. a logical warehouse).

For example:

You may want to split your inventory raw materials and finished goods into different logical warehouses even though they are located in the same physical warehouse.

You maintain warehouses using the Warehouse Maintenance program.

Starting

To use this feature, the following setup option(s) must be enabled/defined:

Setup Options > Configuration > Distribution > Inventory

- Multiple bins

-

Associate serials by bin

This setup option only needs to be enabled if the Serial tracking system required setup option is enabled.

- Fixed bins

- Pick confirmation

-

Marshalling

-

Use marshalling for all customers

The Use marshalling for all customers setup option is only enabled once you have enabled the Marshalling setup option.

- Show Warehouses (hyperlink)

- Marshalling

- Pick confirmation

If you have enabled the Marshalling or Pick confirmation setup options for the first time, you must save your changes, exit SYSPRO and log on again before proceeding with the setup options against the warehouse.

You can secure this feature by implementing a range of controls against the affected programs. Although not all these controls are applicable to each feature, they include the following:

- You restrict operator access to activities within a program using the Operator Maintenance program.

- You can restrict operator access to the fields within a program (configured using the Operator Maintenance program).

- You can restrict operator access to functions within a program using passwords (configured using the Password Definition program). When defined, the password must be entered before you can access the function.

- You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program). Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

- You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

- You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

Solving

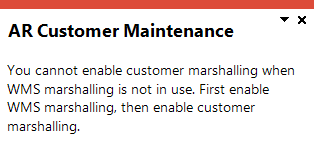

You have attempted to enable the Use marshalling option against the customer within the Customers program, before enabling the Marshalling setup option (Setup Options > Configuration > Distribution > Inventory).

Follow these steps to enable Marshalling against selective customers:

To use Marshalling for the majority of your customers:

-

First, enable the Marshalling and the Use marshalling for all customers setup options (Setup Options > Configuration > Distribution > Inventory).

-

Then disable the Use marshalling option against the customers (Customers program) for those customers that don't use marshalling.

To use Marshalling for a few customers:

-

First, enable the Marshalling setup option (Setup Options > Configuration > Distribution > Inventory).

-

Then enable the Use marshalling option against the customer (Customers program) only for those customers that use marshalling.

Yes, there is.

To use Marshalling for the majority of your customers:

-

First, enable the Marshalling and the Use marshalling for all customers setup options (Setup Options > Configuration > Distribution > Inventory).

-

Then disable the Use marshalling option against the customers (Customers program) for those customers that don't use marshalling.

To use Marshalling for a few customers:

-

First, enable the Marshalling setup option (Setup Options > Configuration > Distribution > Inventory).

-

Then enable the Use marshalling option against the customer (Customers program) only for those customers that use marshalling.

Using

-

Create and end the sales order using the Sales Order Entry program.

-

The SO Picking Options program is displayed where you can choose to create a new pick, add the sales order lines to an existing pick or just release the sales order lines.

-

If the sales order lines are from different warehouses, you can only select the Release for picking option.

-

If the Marshalling setup option is enabled, the bin you select at the Destination bin field must be a dispatch bin in the marshalling area of the warehouse.

-

-

Allocate the lots or serials using the Bins, Lots & Serial Allocation program.

Once the allocations are complete, a pick is generated (if you selected to create a new pick or release for picking).

-

Access the Pick Maintenance program and select the pick status to start the picking process.

-

Pick the stock items and select the status again to complete the pick.

If the Pick confirmation setup option is enabled, a window is displayed where you can select the Send to Pick Confirmation option. The status of the pick will change to F - Confirming.

If the Pick confirmation setup option is disabled, the status of the pick will change to C - Picked.

-

-

Access the Pick Confirmation program to verify the picked stock against the sales order confirm the pick. The lot and serial numbers and quantities can be updated, if required.

Short-picked items are sent to the Lost and found warehouse, or an immediate adjustment journal transaction is created.

You can also confirm the pick by selecting the F - Confirming status within the Pick Maintenance program.

-

Once the pick is confirmed, the Pick Maintenance program is displayed.

If the warehouse is configured as a Pick confirmation and Marshalling warehouse, then pick status is reflected as M - Marshalling, but if only the Pick confirmation setup option is enabled against the warehouse, then the pick status is reflected as C - Picked, which affirms that the pick is completed and you can proceed with the invoicing.

-

Access the Marshalling program to marshall the pick. The top listview displays the pick lines that are available for packing and the bottom listview displays the packing containers, called outers.

You can also marshall the pick by selecting the M - Marshalling status within the Pick Maintenance program.

-

Add a new outer or select an existing outer that is still open (i.e. the outer status is C - Created) and then select the Add to Outer option to pack the selected pick lines into the outer.

-

Then select the Dispatch Outers option to dispatch packed outers. The pick status is then updated to C - Picked, which confirms that the pick is completed and you can proceed with the invoicing of the sales order.

-

Sales order pick statuses are mainly used in the Warehouse Management System.

The following indicates the possible status codes for a sales order pick:

| Status | Description |

|---|---|

| S - Started |

This indicates that the sales order pick has started. It is applied to the pick header and detail lines when you start the picking process. |

| O - Outstanding |

This indicates that the picking process is still required. This status is applied to the pick header and detail lines once a sales order is ended, if the pick is created in one of the following programs:

|

| C - Picked | This applies to the pick header and detail lines and indicates that the sales order pick process is complete. |

|

X - Cancelled |

This status is applied to the pick header when the sales order pick is canceled. |

|

F - Confirming |

This indicates that the picked items have been sent to the relevant warehouse area where they are in the process of being confirmed. This status is applied to the pick header and detail lines once the lines have been picked and the pick is sent for confirmation. |

|

M - Marshalling |

This indicates that the picked items have been sent to the relevant warehouse area where they are in the process of being marshalled. This status is applied to the pick header and detail lines once the lines have been picked and the pick is sent for marshalling, or if the pick confirmation has been completed (if the Pick confirmation setup option is enabled against the warehouse). |

Outer statuses are mainly used in the Warehouse Management System.

The following indicates the possible status codes for an outer:

| Status | Description |

|---|---|

|

C - Created |

This indicates that the outer has been created and may have picked items allocated to it, but has not been dispatched. |

|

D - Dispatched |

This indicates that the outer has picked items allocated to it and has been dispatched. |

The following indicates areas in the product that may be affected by implementing this feature:

Setup Options > Configuration > Distribution > Inventory

We added the Marshalling and Pick confirmation setup options against the warehouse.

A dispatch bin (or marshalling bin) must be defined against the warehouse once these setup options are enabled.

These setup options are only available when accessing the Warehouse Maintenance program from within the Setup Options program.

Program List > Contact Management > Setup

We added the Use marshalling setup option to enable or disable marshalling for specific customers.

Program List > Sales Orders > Picking

The F - Confirming status can be applied to the pick header and detail lines once the lines have been picked and the pick is sent for confirmation.

The M - Marshalling status can be applied to the pick header and detail lines once the lines have been picked and the pick is sent for marshalling.

The status of the pick line can be changed by selecting the line and using the context-senstive menu.

The status of the pick header can be changed at the Pick status field.

Accessible from the Edit hyperlink at the Override Allocation column within the Pick Maintenance program.

When this program is called from within the Pick Confirmation program to update the quantity, lot and or serial numbers, then the dispatch bin can't be changed.

Accessible from the End Order function in the Sales Order Entry program.

A pick can only consist of sales order lines created within the same picking warehouse.

If a sales order has multiple lines from different picking warehouses, you will be forced to release the sales order lines for picking by either creating a new pick or add the lines to an existing pick.

Program List > Warehouse Management > Picking > Transaction Processing

This program lets you confirm lines on a sales order pick.

Program List > Warehouse Management > Picking > Transaction Processing

This program lets you consolidate, split, and package picks (i.e. place picks in an outer) in preparation for dispatch.

Program List > Sales Orders > Picking

A pick can only consist of sales order lines created within the same picking warehouse.

An error message is displayed if the user attempts to add sales orders lines from a different warehouse to the pick.

Program List > Sales Orders > Picking > Reports

This program lets you generate a list of sales order pick lines and the outers in which the stock was packaged or dispatched.

Program List > Sales Orders > Picking > Reports

This program lets you generate labels for outers in which sales order picks are packaged and dispatched.

Program List > Sales Orders > Picking > Reports

This program lets you generate a list of sales order picks that can be filtered according to bins, warehouses, customers, sales orders or jobs, pick numbers, pick statuses and pick dates.

Program List > Sales Orders > Picking

This program lets you view the contents of an outer (i.e. the sales order pick lines that were added to the outer).

The status of the outer may be C - Created or D - Dispatched.

Program List > Sales Orders > Picking

The new pick statuses F - Confirming and M - Marshalling are displayed against the pick header and detail lines.

Program List > Inventory > Warehouse Management > Missions and Tasks > Browses

This program lets you view information on outers that have been created or dispatched.

Accessible from the Dispatch Outers function within the Marshalling program.

This program lets you dispatch verified and packed boxes, called outers.

Program List > Inventory > Browses

We added the Pick confirmation and Marshalling columns to the listview, which will display Yes or No per listed warehouse.

Program List > Sales Orders > Picking > Browses

Picks that require marshalling can be included in the list by selecting the Marshalling option.

The following indicates the business objects that are affected by this feature:

The SO Pick Allocation Override business object lets you override a stock item's original bin, lot or serial that was allocated for picking. The updated allocation information is saved in the SorPickAmendJnl table.

The SO Release Sales Orders to Picking business object lets you create a new pick on the sales order line as well as add the sales order line to the existing pick.

The SO Pick Status Change business object lets you change the status of a pick from S - Started to F - Confirming, X - Cancelled or C - Picked.

The business object also changes the status of pick lines.

The WHM Add/Delete Outer business object lets you add or delete an outer.

The Marshalling business object lets you indicate the pick line of the pick number that you want to add or remove from the selected outer, the pick to be added or removed from the selected outer as well as the packed quantity that you want to add to the outer (which can be equal to or less than the picked quantity).

The WHM Dispatch Outers business object lets you indicate the outer that you want to dispatch.

The SO Create Pick From SO Released to Pick business object lets you create or add to an existing pick. The information that you can indicate when creating or adding to existing pick includes the bin, lot number, quantity required, sales order number, sales order line number and serial number.

The SO Pick Query business object lets you query sales order picks and display the pick lines for the entered pick number. Pick line details include the quantity in picking, the sales order line attached to the pick, and the status of each pick line.

The Pick Selection Query business object lets you query information about pick lines that are outstanding, have been invoiced, packed in outers according to specified customers, sales order numbers, pick numbers and dates.

The Pick Outer Details business object lets you query pick outers according to whether they are ready to dispatch, have a status of dispatched or created as well as the outers that you want to query. Additionally, you can restrict the number of documents that are generated.

Copyright © 2026 SYSPRO PTY Ltd.