You use this program to maintain cost elements against stock items used in the Landed Cost Tracking system.

The LCT system provides an alternative to the cost multiplier facility that is configured within the Inventory module (Inventory Warehouse Maintenance for Stock Code).

Although you can use the cost multiplier facility in conjunction with the LCT system, the two methods of attempting to calculate the non-merchandise cost elements are mutually exclusive (i.e. You cannot use both for the same receipt of the same stock code).

| Field | Description |

|---|---|

| Element |

Indicate the code of the cost element to add or update. Each element represents a type of cost that you may incur when moving an item from the supplier to your warehouse. For example: Freight, duties and brokerage would be typical costs incurred when purchasing an item from a foreign supplier. You would configure each of these costs as an element. A more detailed breakdown of costs can be maintained by creating multiple elements for a single type of cost. For example: You could create an element for each of the different types of shipping methods (i.e. Air, truck, rail, or ship). The elements for each applicable stock code are grouped into a Bill of landed costs. The sum of the bill comprises the expected costs of moving an inventory item from the supplier to your warehouse. Each element maintains both the expected and actual cost. The expected cost is calculated using the Calculate New Landed Cost program, while the actual costs are apportioned from invoices posted in the Accounts Payable Invoice Posting program. The elements do not determine the expected cost amount. This is determined by the calculation code. The result of the calculation is stored as the expected cost element value. When you create the bill of landed costs you enter the appropriate cost element and calculation codes for each entry in the bill. Fixed cost elements are apportioned when a purchase order is attached to a shipment. All other element types are calculated based on the calculation code and apportionment only occurs during invoice posting. See Restrictions and limits in Notes and warnings |

| Where Used | Select this to use the LCT Where-used Elements program to view the stock code(s) against which the element is used. |

| Field | Description | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Element |

This displays the code of the cost element currently being maintained |

||||||||||||||||

| Description | This indicates the description assigned to the cost element. | ||||||||||||||||

| Supplier | Indicate the supplier who provides you with the service

represented by the cost element. This field is

mandatory. This supplier is used as the main supplier when adding sundry items to the shipment as well as including fixed costs. It is also the supplier which is pushed through to the journal for each element line which is posted to the journal. You are not required to post the invoice to the element supplier.

|

||||||||||||||||

| Supplier description | Displays the name of the supplier selected. | ||||||||||||||||

| Currency |

Indicate the currency in which the supplier will charge you for services, which is the currency in which you will enter the expected rate. It defaults to the currency of the supplier (Suppliers). |

||||||||||||||||

| Currency description | Displays the description of the currency selected. | ||||||||||||||||

| Use fixed cost |

Select this to assign a fixed cost to the element that can be applied to a specific route. The fixed cost can either be an entered amount, or a variable fixed cost defined using a calculation code that is calculated and then apportioned over the shipment as a fixed cost. Fixed cost elements are apportioned when a purchase order is attached to a shipment. You can only select this option when you add a new element. Because different routes (e.g. Sea, Air, etc.) attract different costs, these fixed costs are held against the route codes (Browse on Routes) and are automatically distributed over the items in the container according to the apportionment method attached to the element. They are not stock code dependent and actual costs are calculated at the time of posting the invoice.

|

||||||||||||||||

| Fixed cost |

Enter the fixed cost amount to use for this element. You typically enter a fixed cost where, for example, a container is brought in with fixed costs attached, regardless of its contents. This option is only available if you selected the option: Use fixed costs. |

||||||||||||||||

| Fixed cost code | Indicate the calculation code to use to calculate the

cost and then apportion it over the shipment as a fixed

cost. The Apportionment method to use determines how the calculated fixed cost is distributed. This is useful if, for example, you need to pay duty for a shipment that was agreed with Incoterms code FOB (free on board) and customs then calculate the duty based on the supplier's invoice price + the freight cost to the point of entry. |

||||||||||||||||

| Minimum charge | Indicate a minimum charge to assign to the element. This value is used only if the calculated cost for the element is less than the minimum charge. This also applies only to the expected cost. | ||||||||||||||||

| Expected rate | Specify a value that can be used to calculate the

expected cost of the service represented by the cost element.

The calculation of the expected cost of the element does not have to include this expected rate amount. To include the expected rate amount in a calculation, enter the reserved word RATE in one of the fields in the calculation. Enter the rate in the currency specified at the Currency field. If the currency is foreign then the expected rate is converted to local currency at the exchange rate prevailing when the expected rate is to be used. When adding a new cost element, the rate defaults to a value of 1. |

||||||||||||||||

| Rate description | Indicate the description for the expected rate (e.g. $ per kilogram). | ||||||||||||||||

| Apportionment method |

Indicate the basis (e.g. weight, value, volume, etc.) according to which you want to allocate the invoice amount to each line of the purchase order included in the shipment. When calculating the apportionment values the Invoice Posting program processes only those purchase order lines included in the shipment where the cost element has been applied. Once the actual value for each purchase order line has been determined then the actual cost for each element is updated by this value. If you selected the option: Convert all quantities unit of measure (Purchase Orders Setup) then you can use an alternate unit of measure as the base of any apportionment. If a purchase order is raised using an alternate unit of measure, the quantity is converted to the stocking unit of measure on all lines of the shipment. This means that when apportionments are done, all the lines are based on the same unit of measure.

|

||||||||||||||||

| Apportionment code |

Indicate the calculation code that you want the system to use to apportion the invoice amount. This only applies if you selected CALC at the Apportionment method field. |

||||||||||||||||

| Sequence |

This indicates the sequence number that will be used to sort cost element codes. This defaults to the number 10 and is only used to sequence your cost elements for reporting/query purposes. For example: If you have entered FREIGHT, POSTAGE and DUTY as the cost elements for a stock code, then the Shipment Tracking Report prints these elements alphabetically as: DUTY, FREIGHT and POSTAGE. However, you can change the sequence in which these elements are printed by assigning a sequence number to each element. |

||||||||||||||||

| Credit ledger code |

This indicates the ledger account to which postings are made for each cost element when receiving a shipment into stock. If left blank, then the credit amount is posted to the Non-stocked control account (General Ledger Integration). You can access this field only if Inventory is linked to General Ledger (General Ledger Integration) and:

You cannot access this field if:

In this case, the credit ledger code used is always the GRN suspense control account (General Ledger Integration). |

||||||||||||||||

| Credit ledger code description | This indicates the description of the credit ledger code selected. | ||||||||||||||||

-

An element can only be linked to a single supplier.

If you have multiple suppliers who provide you with the same type of element (for example Insurance), then you need to create an element for each one (for example element InsuranceRoad linked to Supplier1, element InsuranceRail linked to Supplier2, etc).

-

You can only delete an element when it is not used against a stock code or route in a bill of landed costs.

You can use the Where Used option to use the LCT Where-used Elements program to view the stock code(s) against which the element is used.

For a Fixed cost element, the stock code can be displayed as Fixed cost in the LCT Where-used Elements program. Although Fixed cost is not a stock code, it means that the element is in use against a Route. Fixed cost elements are setup against the Route (associated fixed costs), so to be able to delete the fixed cost element, you need to find the Route/s that this element is associated with, and remove it from the route/s.

Electronic Signatures provide security access, transaction logging and event triggering. This enables you to increase control over your system changes.

Access to the following eSignature transactions within this program can be restricted at Operator, Group, Role or Company level. You configure this using the eSignature Setup program.

| eSignature Transaction | Description |

|---|---|

| PO LCT Add an Element |

Controls access to the addition of an LCT element in the LCT Elements program. |

| PO LCT Change an Element |

Controls access to the maintenance of an LCT element in the LCT Elements program. |

| PO LCT Delete an Element |

Controls access to the deletion of an LCT element in the LCT Elements program. |

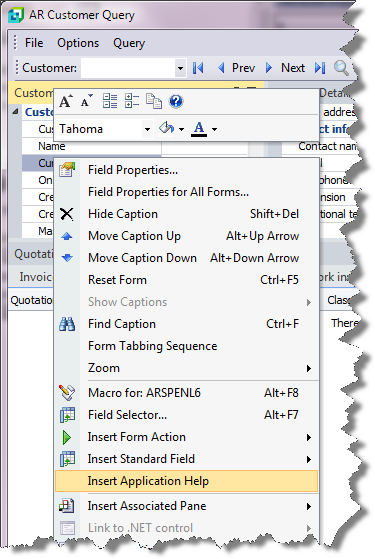

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.

![[Note]](images/note.png)