You use this program to post miscellaneous transactions or standard transactions against specific serial numbers.

| Field | Description | ||||

|---|---|---|---|---|---|

| Transaction type | |||||

| Standard | Select this to post a standard transaction (i.e. one catered for by the system) against a serialized item. | ||||

| Miscellaneous | Select this to post a transaction against a serial

number that does not relate to any of the standard transaction

types provided. The transaction quantity entered does not affect the on hand quantity against the serial number or the stock code. |

||||

| Function | This option only applies if you selected to process a Standard transaction type. It enables you to indicate the type of standard transaction you want to process. | ||||

| Take on sales transactions |

You use this to assign a serial number to an item that was previously sold to a customer, but where the sale has not yet been recorded against the serial number. This function reduces the serial quantity on hand and quantity available, but does not affect the Inventory quantity on hand and available quantities. The transaction code for this process is SALES. |

||||

| Maintenance |

Select this to record changes or service work performed on a serialized item or a batch of serialized items. This function does not affect Inventory on hand quantities. The transaction code for this process is MAINT. |

||||

| Customer unit in for service | Select this to record that a customer has returned a

serialized item to be serviced. This function can only be used for Manual serial items. These items are included in the Allocated to sales orders quantity displayed in the Warehouse Values section of the Inventory Query program. You cannot perform the following transactions while a customer unit is in for a service:

The transaction code for this process is SRVIN. |

||||

| Unit returned to customer | Select this to record the return to a customer of a

unit that was sent in for a service. This function can only be used for manual serial items. The transaction code for this process is SRVRET. |

||||

| Unit loaned to a customer | Select this to record that a serialized item has been

loaned to a customer. This function can only be used for manual serial items. These items are included in the Allocated to sales orders quantity displayed in the Warehouse Values section of the Inventory Query program. You cannot perform the following transactions while a unit is on loan to a customer:

The transaction code for this process is LOAN. |

||||

| Unit returned by customer | Select this to record that a unit on loan to a customer

has been returned. This function can only be used for manual serial items. The transaction code for this process is RETURN. |

||||

| Transfer between warehouses |

Select this to record the transfer of serialized items between warehouses. You typically use this function to record the transfer of items if this has not previously been recorded using the Inventory Movements program. This function affects the serial on hand and available quantities, but not the Inventory on hand and available quantities.

The transaction code for this process is TRA. |

||||

| Receive goods in | Select this to receipt a quantity against the entered

serial number. This function does not affect Inventory quantities, but it does affect the on hand and available quantities against the serial number. The transaction code for this process is REC. |

||||

| Additional notes | Select this to assign a comment against a serialized

item. You can delete any additional notes entered against serial items using the Serial File Purge program. This is done by indicating that you only want to delete serial transactions of the type NOTE. The transaction code for this process is NOTE. |

||||

| Warranty details | Select this to record any maintenance that has been

performed on an item that is included under the item's

warranty. This function can only be used for manual serial items. The transaction code for this process is WARR. |

||||

| Change location within warehouse | Select this to record that an item has been moved to a

new location within the same warehouse. The on hand quantity of all items with the entered serial number is moved to the new location. The transaction code for this process is MOVE. |

||||

| Unit sent to service depot | Select this to record that you have sent the serial

item to the service depot for maintenance. This function can only be used for manual serial items. You cannot perform the following transactions while a unit is at the service depot:

The transaction code for this process is DEPOT. |

||||

| Received back from depot | Select this to record that a serial item has been

returned from the service depot. This function can only be used for manual serial items that are currently residing at the service depot. The transaction code for this process is DEPRET. |

||||

| Issue to work in progress |

Select this to record the issue of a serial item to a job. This function does not affect Inventory quantities or the job value, but it does affect the on hand and available serial quantities (i.e. the program does not update any WIP records, only the serial records). The transaction code for this process is ISS. |

||||

| Adjust quantity on hand | Select this to correct discrepancies between the

inventory quantity on hand and the serial quantity on hand for

an item. This function does not affect Inventory quantities, but it does affect the on hand and available quantities for the serial item. The transaction code for this process is PHY. |

||||

| Post | Select this to post the transaction. | ||||

![[Note]](images/note.png)

|

|

|

Only the fields applicable to the Transaction type and the Function you selected are enabled. |

|

| Field | Description |

|---|---|

| Transaction date | Indicate the date of the transaction. This defaults to the current system date. |

| Reference | Indicate a journal reference that you want to assign to the transaction. This reference can be printed on the Serial Tracking Report report. |

| Quantity |

I indicate the transaction quantity you want to post. For a batch serial number you can enter any quantity, providing it does not exceed the quantity available for the batch. For a manual serial number the value can only be 1 or -1. |

| Customer | Indicate the code of the customer involved in the

transaction. You cannot access this field if you specified a job number at the Job field. |

| Name | This indicates the name of the customer specified. If the customer is not on file, then this field is enabled to allow the customer's name to be entered. |

| Supplier | Indicate the code of the supplier involved in the

transaction. You cannot access this field if you specified a job number at the Job field. |

| Supplier name | This indicates the name of the supplier specified. If the supplier is not on file, then this field is enabled to allow the supplier's name to be entered. |

| Job |

Indicate the job number associated with the transaction or to which you want to issue the serialized item. You cannot access this field if you specified a supplier at the Supplier field or a customer at the Customer field. |

| Notation | Indicate the journal notation that you want to assign to the transaction. This notation is printed on the Serial Tracking Report report. |

| Revision | Indicate the revision level of the unit maintained or serviced. This notation is printed on the Serial Tracking Report report. |

| New location | Indicate the new location for the item. |

| Target warehouse | Indicate the warehouse to which you want to transfer the item. |

| Target wh description | This indicates the description of the target warehouse. |

| Value | Indicate the total value of the transaction. |

| Due date | Indicate the date on which the service must be complete so that the unit can be returned to the customer or the date when the customer must return the item or the date when the unit will be returned from the depot. |

| New expiry date | Indicate a new expiry date for a manual serial number. |

![[Note]](images/note.png)

|

|

|

Only the fields applicable to the Transaction type and the Function you selected are enabled. |

|

| Field | Description |

|---|---|

| Function | This indicates the Function you selected and only applies to Standard transaction types. |

| Transaction code |

This indicates the code that will be assigned to the transaction selected. This only applies to a Miscellaneous transaction type. |

| Serial number | Indicate the serial number of the item for which you want to post the transaction. |

| Serial method | This indicates whether the serial entered is a Manual or a Batch serial. |

| Warehouse |

Indicate the warehouse in which the serialized item resides. You can only access this field for batch serial numbers. This enables you to post a transaction against the warehouse in which a specific portion of the batch is stocked. |

| Wh description | This indicates the description of the warehouse code. |

| Stock code | This indicates the stock item associated with the serial number specified. |

| Stock description | This indicates the description of the stock item. |

| Location | This indicates the physical location of the item. |

| Customer | This indicates the customer associated with the last transaction posted against the serial. |

| Total receipt qty | This indicates the total quantity of stock items assigned to the serial number when it was received into stock. |

| On hand qty | This indicates the quantity of the stock on hand for the serial number/stock code combination. |

| Available qty | This indicates the quantity of the serial number/stock code combination that is available to use. |

| Due date | This indicates the date when the service is expected to be completed. |

| Unit status | This indicates the current status of the serial.

For a Warranty details transaction, this will indicate either "At service depot" or "Out on loan" For a Unit sent to service depot and Received back from depot transactions, this will indicate either "In for service" or "At service depot" or "Out on loan". For a transaction, this will indicate either |

| Warning | This indicates additional information relative to the transaction. |

-

The same serial number can be allocated to different stock codes when the option: Use same serial for multiple stock codes is enabled (Inventory Setup). The Browse on Serial Numbers program is loaded, enabling you to select the serial number/stock code combination for which to maintain transactions.

-

If you enter a serial number that exists in a warehouse to which you do not have access (Operators) then the message: Serial number not on file or access has been denied is displayed.

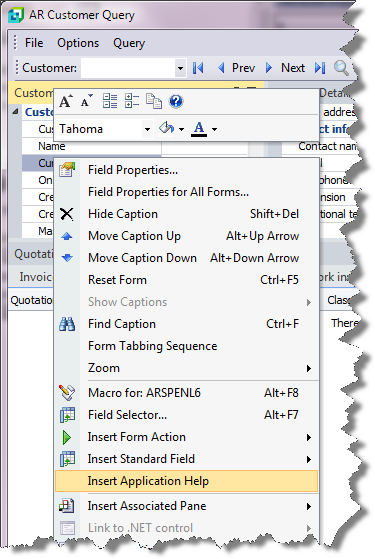

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.