You use this program to define details of new lot numbers you want to add to the system for specific stock items.

| Field | Description |

|---|---|

| New | Select this to add a new lot. |

| Save | Select this to save the information you entered. |

| Stock code | Indicate the stock item for which you want to add a new lot. |

| Warehouse | Indicate the code of the warehouse in which the new lot

must be allocated. You cannot use warehouses to which you have been denied access (Operators). |

| Edit | Once you enter a lot number, you can select this to use the Multimedia program to view or maintain multimedia objects for the lot. |

| Field | Description | ||||

|---|---|---|---|---|---|

| Lot number details | |||||

| Stock code | This is the stock item to which the new lot must be assigned. | ||||

| Stock code description | This is the description of the Stock code. | ||||

| Warehouse | This indicates the warehouse in which the new lot must be created. | ||||

| Warehouse description | This indicates the description of the warehouse. | ||||

| Lot |

Assign a lot number to the stock item. You can re-use the same lot number for different stock codes if you selected the option: Use same lot on multiple stock codes (Lot Traceability Setup). |

||||

| Bin |

Indicate the specific bin to which the lot must be allocated. This only applies if you are using multiple bins against the warehouse (Warehouses). If Multiple bins are not required for the Warehouse in which the new lot must be created, then this field is set to equal the warehouse (based on the InvMultBin record) and cannot be changed. The Expiry date you enter below applies only to this bin in the warehouse selected above. |

||||

| Rev/Rel | This information is only applicable if the stock item is defined as ECC controlled (Stock Codes). | ||||

| Revision | Indicate the revision number of the stock item to which you want to assign the lot number. | ||||

| Release | Indicate the release of the stock item to which you want to assign the lot number. | ||||

| Lot information | |||||

| Original qty received |

Indicate the original quantity of the stock item assigned to the lot. Although the lot can be created with no stock quantity on hand, you need to enter a quantity in this field if, at a later stage, you want to be able to process a credit note against the lot based on the credit note quantity entered, or you want to process negative issues against the lot without performing an actual Receipt transaction. For example: You are using the Sales Order Entry program to generate a credit note for a lot traceable item. The credit note is for a quantity of 10 and is not linked to the original invoice. When you create a new lot number for the credit note, you need to enter the full credit note quantity in this field (i.e. 10 in this example). If you enter any quantity less than 10, you will not be able to credit the full credit note quantity (i.e. 10) against this lot. Refer to the Original Quantity Received for Lots section in Notes and warnings for additional information. |

||||

| Expiry date |

Indicate the expiry date of the lot. This defaults to 00/00/00. If you are depleting lots manually, then a lot with an expiry date of 00/00/00 never expires.

The order in which lots are depleted is determined as follows when the option: Automatic depletion of lots by - Expiry date (Inventory Setup) is selected:

|

||||

The OrigQtyReceived column in the LotDetail table is used as a control when receiving in lot traceable items to ensure that you cannot credit or return more than originally received when, for example, processing a credit note in Sales Order Entry or processing a negative material issue using the WIP Job Issues program.

When the quantity being credited exceeds the quantity in the OrigQtyReceived column, you will be unable to process the credit transaction, irrespective of the Quantity available or the Quantity on hand for the lot.

The OrigQtyReceived column should only be updated when receiving in stock using from an Inventory receipt, a Job receipt or a Purchase order receipt. However, it can be manually updated when adding a new lot using the Lot Maintenance program by entering a positive quantity in the Original qty received field. It can also be updated by enabling the Update original quantity received option when processing adjustments using the Stock Take Confirmation program or the Inventory Movements program.

It is important to note the following when processing adjustments for lot traceable items using either the Inventory Movements or Stock Take Confirmation program:

-

If you do not enable the Update original quantity received option, then you may not be able to process credit notes or negative material issues at a later stage, as the OrigQtyReceived will be insufficient to do so.

-

The option to update the original quantity received was only introduced into the Inventory Movements and Stock Take Confirmation programs in SYSPRO 7 Update 1, so adjustments processed prior to this will not be included in the OrigQtyReceived.

-

The Update original quantity received option must be consistently applied when processing adjustments in these programs. You should not sometimes enable the option and sometimes not enable it, especially when processing negative adjustments, as this can result in inconsistent results in the OrigQtyReceived column, which could lead to problems when you try to return an item to the lot.

Note that the Update original quantity received option is disabled by default.

-

It is possible for the original quantity received column in the LotDetail table to contain a zero or even a negative quantity when you do not consistently enable the Update original quantity received option.

For example:

The following steps will result in a negative value in the OrigQtyReceived column of the LotDetail table:

-

Using the Lot Maintenance program, you add a new lot and you leave the Original qty received field as zero.

-

Using the Inventory Movements program, you process a positive Adjustment for a lot traceable item using this new lot and you do not enable the Update original quantity received option.

-

Using the Inventory Movements program, you process a negative Adjustment for the same lot traceable item and lot number, but this time you enable the Update original quantity received option.

-

Electronic Signatures provide security access, transaction logging and event triggering. This enables you to increase control over your system changes.

Access to the following eSignature transactions within this program can be restricted at Operator, Group, Role or Company level. You configure this using the eSignature Setup program.

| eSignature Transaction | Description |

|---|---|

| Lot number added |

Controls access to the New Lot or Add functions in the Lot Maintenance, Browse on Lots and Lot Number Maintenance programs. |

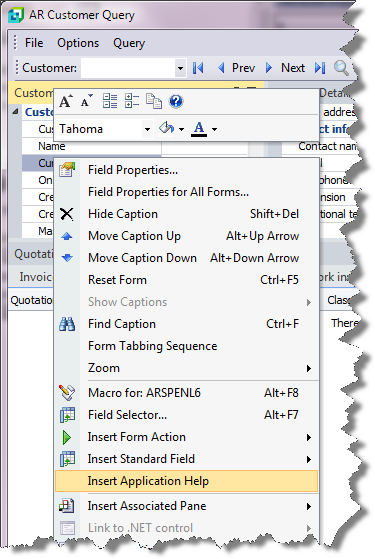

Inserting Application Help

You would typically follow this procedure to display help for the current program in a customized pane that can be pinned to the program window.

Information includes step-by-step instructions for the various functions available within the program, including a brief overview of what the program does, what setup options are required and how to personalize the program.

-

Open the program for which you want to insert application help into a customized pane.

This functionality is only available for a program that has panes.

-

Right-click any form field.

You can also click the triangle menu icon that appears in the title area of a pane.

-

Select Insert Application Help from the context-sensitive menu.

The application help appears in a pane within your program. You can reposition the pane using the docking stickers or pin it to the program window.

Removing the Application Help pane

If you no longer want to display application help in a pane for your current program, you can simply remove it.

-

Select the Close icon in the right-hand corner of the application help pane.

-

Confirm that you want to delete the pane.

![[Note]](images/note.png)