Job Nesting

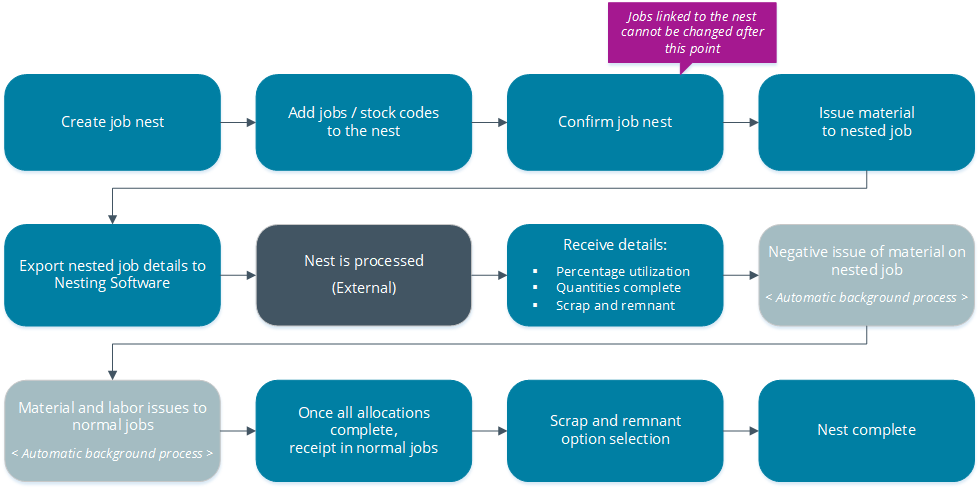

The Job Nesting feature lets you combine several small jobs into one larger nested job process. This lets you view and select combinations of work orders that can be batched together into larger processes (e.g. you can nest multiple jobs using the same raw material or components).

The result is a reduction of waste and operational costs, optimized use of raw material and resources, and improved efficiencies.

Exploring

Nested-based machining typically involves placing a single sheet of material on a CNC router table. The router is programmed to process components based on the machine's capabilities, in a single setup without any material handling required, other than loading and unloading.

The Production Planner typically chooses any combination of work orders to nest together based on their sharing a commonality (such as the same raw material or the same work center) to create a combined job nest.

The components in a nested-based process are positioned in a pattern that will achieve the best possible material utilization.

For example:

When making a pair of denim jeans, the fabric is laid out and the pattern cut based on the different parts of the jeans (e.g. front, back, pockets and waist).

A group of jobs, processed together as a percentage of the material and labor used.

The result of an ability to view and select combinations of worksorders that can be batched together. The nest or project nest is the aggregrate single view of the batch.

This is the integration interface that provides a link between ERP systems and a dedicated nesting software.

Nesting refers to the process of efficiently manufacturing shaped and non-symmetrical parts from flat raw material.

The components in a nested-based process are positioned in a pattern that will best use the materials and minimize waste.

External generic or machine-specific software that performs the optimization of the nest against the raw materials.

A part or quantity that is left over after the greater part has been used, removed or destroyed.

Remnants are receipted back into stock for future use.

Scrap is material that falls outside of specification and which has characteristics that make it impractical to rework. Within SYSPRO, you can associate a description to a code that describes the reason you need to scrap the material.

Starting

To use this feature, the following setup option(s) must be enabled/defined:

Setup Options > Configuration > Distribution > Inventory

- Associate serials by bin

You can secure this feature by implementing a range of controls against the affected programs. Although not all these controls are applicable to each feature, they include the following:

- You restrict operator access to activities within a program using the Operator Maintenance program.

- You can restrict operator access to the fields within a program (configured using the Operator Maintenance program).

- You can restrict operator access to functions within a program using passwords (configured using the Password Definition program). When defined, the password must be entered before you can access the function.

- You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program). Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

- You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

- You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

General

- A valid nest job will only have one operation for the specified work center and only one allocation linked to that operation.

-

Non-stocked jobs can only be added to a nest, if the non stock job has an operation linked to a stocked material allocation.

- Operations must be linked to the material allocation via the operation/offset.

- If you have a multi-level BOM, you must create sub-jobs for the made-in items.

-

If you issue a quantity of more than one for a stock code to a nest (without a sheet number) then when you capture the percentage utilization for that item, it will be of the total, not per sheet.

This is useful for punch cutting where multiple sheets are used, but the same items are cut per sheet.

Job linking

- Once jobs are linked to a nest, you can't modify the job. Material and labor can still be posted to non-linked allocations.

-

When a job is linked to a nest, the date calculation method is set to Manual, so that the job will be excluded from any MRP calculations.

If you add a job to a nest and then subsequently remove it from the nest while in the planning phase, you will need to revert the job date calculation method manually.

-

All jobs linked to a nest must have a common work center.

A job can be linked to multiple job nests, but an allocation can only be linked to one nest.

Traceability

- The job nest stock code (i.e. the raw material) cannot be a manual serialized item.

- If you want to trace an item back to an individual sheet, then you need to supply a sheet number that is unique per job nest.

- You can only issue one lot (or one serial) per raw material, so that the parts can be tracked correctly back to the raw material.

The Setup Options program lets you configure how SYSPRO behaves across all modules. These settings can affect processing within this program.

Setup Options > Configuration > Distribution > Inventory

- Associate serials by bin

Solving

-

Open the Job Nest Capture program (Program List > Work in Progress > WIP Job Nesting).

-

Capture the job nest information.

-

Add jobs to the nest using the Job Nest Review.

-

Add raw materials to the nest.

This is the raw material from which the parts will be cut. It doesn't have to match the material allocation on the job.

For example: Grade A steel could be used instead of Grade B, as it is a suitable substitute.

-

Assign which raw material will be used for the job nest (i.e. which sheet will be used).

-

Confirm the job nest.

-

Save your changes.

When saving the nest, new jobs are created for BOMs that were added.

-

Open the WIP Nest Processing program (Program List > Work in Progress > WIP Job Nesting).

-

Select the job nest you want to process.

-

Issue all the required raw materials to the nest.

Once you have issued material, the nest status is set to I - In progress and you can't edit the nest using the Job Nest Capture program. -

Process the job nest, entering the stock utilization, remnant or scrap percentages.

-

Complete the job nest.

This sets the status to F - Finished/Complete.

-

Open the WIP Nest Format Maintenance program.

-

Capture the relevant information in the Format Header.

-

Once the header fields have been captured, the Format Fields pane is populated.

-

Select Save and exit the program.

- Open the WIP Nest Cost History Query program (Program List > Work in Progress > WIP Job Nesting).

-

Select the stock code and warehouse.

You can view the following information:

- The status of a job nest.

- All transactions linked to a job nest.

- Values and costs of a job nest.

A job nest can only be edited when the status is P - Planning or C - Confirmed.

It can't be edited once the status is I - In progress.

You can't maintain a job once it has been allocated to a job nest. You must remove the job from the nest, then perform the required maintenance, and then re-add the job to the nest.

Using

The programs related to this feature are accessed from the Program List of the SYSPRO menu:

- Program List > Work in Progress > WIP Job Nesting

- Program List > Work in Progress > Setup

-

Create and confirm a job nest using the Job Nest Capture program.

Once jobs are linked to a job nest, they can't be modified.

- Assign raw material to the job nest using the Job Nest Capture program.

-

Process the job nest and issue material and labor using the WIP Nest Processing program.

-

Export the job nest to the external nesting software using the Job Nest Capture program.

The nest is processed and information sent back to SYSPRO.

-

Import the job nest details to update information such as percentage utilization, quantities complete and scrap / remnant amounts.

After the import, the following occurs automatically in SYSPRO:

- issuing of negative material and labor on jobs to distribute costs in the nest.

- issuing of material and labor to jobs using the WIP Job Issues and WIP Labor Posting programs.

- depending on the option selected at the Scrap from job nest field in the Work Centers program, the remaining materials will be either scrapped (posted to the GL account) or received back into stock (in a remnant bin).

-

Complete the job nest using the WIP Nest Processing program.

Copyright © 2026 SYSPRO PTY Ltd.