Non Conformance Standard

This program lets you create a standard against which a non-conformance report can be raised.

Exploring

Things you can do in this program include:

-

Assign a non conformance type to a standard.

-

Assign a process and severity level to a standard.

-

Link documents and reports to the standard.

This program is accessed from the Program List of the SYSPRO menu:

- Program List > Quality Management > Non Conformance Reporting > Setup

The non-conformance process is a systematic procedure used by organizations to identify, document, analyze, and resolve deviations from established standards, specifications, or regulations.

This process typically involves several steps, including the initial detection of a non-conformance, the creation of a non-conformance report, root cause analysis, implementation of corrective and preventive actions, and verification of effectiveness. The goal of the non-conformance process is to ensure that issues are addressed promptly, preventing recurrence and promoting continuous improvement in quality and compliance.

A non-conformance standard refers to the established criteria or benchmarks that define acceptable performance, quality, or compliance for products, services, or processes. When these standards are not met, it results in a non-conformance. The standard serves as a reference point for evaluating deviations and determining the necessary corrective or preventive actions to ensure alignment with industry regulations or internal requirements.

A non-conformance report (NCR) is created when a transaction deviates from the non-conformance standard.

Non-conformance types are used to describe the type of deviation that occurred, which could be the following:

-

Product non-conformances occur when a product fails to meet specified quality or performance standards, such as dimensional inconsistencies or material fault. A type of product non-conformance could be a defect.

-

Process non-conformances involve deviations in the execution of operational processes, leading to issues like incorrect procedures or failure to follow established protocols. A type of process non-conformance could be an incorrect product assembly.

-

Regulatory non-conformances arise when operations or products do not comply with industry regulations or legal requirements, potentially resulting in fines or penalties.

-

Supplier non-conformances occur when materials or components received from suppliers do not meet agreed-upon quality or specification standards.

Severity levels are set against the standard within the NCR and CAPA (Non-conformance reporting and Corrective actions / Preventative actions) functionality. The following severity levels categorize the impact and help prioritize actions and resources based on the severity and and urgency of a non-conformance:

-

Critical

A non-conformance that poses a significant risk to safety, regulatory compliance, or product functionality, often requiring immediate corrective action. Critical issues can halt operations or lead to severe consequences.

-

Major

A serious non-conformance that impacts product quality or processes but does not pose immediate safety risks. While not as urgent as critical issues, major non-conformances still require prompt action to prevent further problems.

-

Minor

A less severe non-conformance that has minimal impact on product quality or performance. It may not require immediate correction but should be addressed to avoid potential escalation into larger issues.

-

Log only

Minor deviations that do not impact quality, safety, or compliance. These are often recorded for tracking purposes but typically do not require corrective actions.

Starting

-

The Quality Management module must be installed.

You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program).

Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

Controls access to the creation of a new conformance standard in the Non Conformance Standard program.

Controls access when maintaining a standard in the Non Conformance Standard program.

Controls access when deleting a standard in the Non Conformance Standard program.

You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

The following configuration options in SYSPRO may affect processing within this program or feature, including whether certain fields and options are accessible.

To use this feature, the following setup option(s) must be enabled/defined:

Setup Options > Keys > Manufacturing

-

-

Suppress leading zeros

-

Presentation length

Solving

Documents and reports can only be linked to existing non conformance standards, i.e. you have to save a newly created standard first before attaching documents or linking reports to it.

Using

-

Columns in a listview are sometimes hidden by default. You can reinstate them using the Field Chooser option from the context-sensitive menu (displayed by right-clicking a header column header in the listview). Select and drag the required column to a position in the listview header.

-

Press Ctrl+F1 within a listview or form to view a complete list of functions available.

-

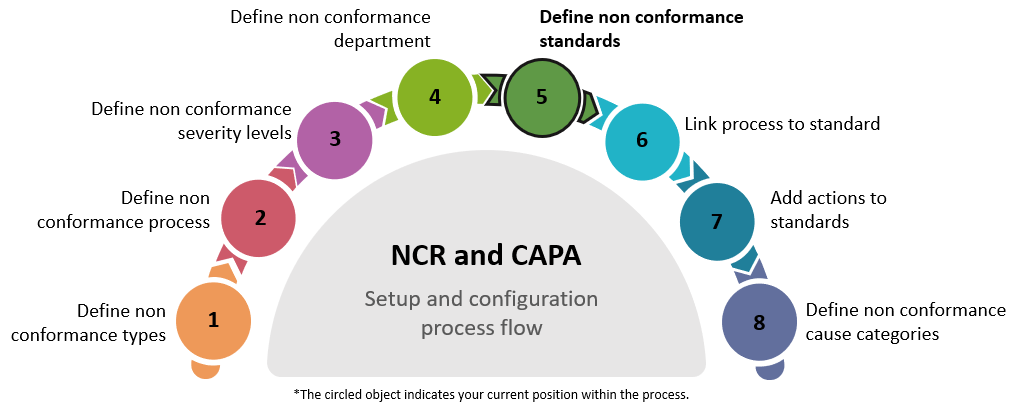

Define the non conformance types using the Non Conformance Type program.

-

Define the process that will be followed once a non-conformance is raised using the Non Conformance Process program.

-

Define the severity levels that will apply to the non conformance using the Non Conformance Severity Level program.

-

Use the Non Conformance Department program to define the departments that will own, address and resolve the non conformance issue, and to add both the default and any other necessary stakeholders for each department.

-

Define the non conformance standard using the Non Conformance Standard program by linking the type, severity level and departments to the standard.

-

Link the process to the standard using the Non Conformance Process Per Standard program

-

Link the corrective and preventative actions to the standard using the Non Conformance Standard Actions program.

-

Define the cause categories into which the non conformance incidents can be grouped using the Non Conformance Cause Category program.

Referencing

This lets you enter a new or select an existing non conformance standard code.

This lets you attach a document to the NCR standard, as well as detach or view an attached document.

The document attached here can be viewed when selecting the View document hyperlink at the Standard document field within the Non Conformance Report Maintenance program.

A document can only be added to an existing non conformance standard, i.e. you must save a newly created standard first before attaching a document.

This lets you link a report to the NCR standard.

A report can only be linked to an existing non conformance standard, i.e. you must save a newly created standard first before linking a report to it.

Non conformance standards are saved in the SqmNcStandard table.

| Field | Description |

|---|---|

|

Description |

This lets you enter a description for the non conformance standard. |

|

Department |

This lets you select the NCR department, that owns the non-conformance and is accountable for addressing and resolving it. |

|

Type |

This lets you select the type of deviation that could occur and would be linked to the NCR standard. |

|

Process |

This lets you select the process that must be followed per standard. |

|

Severity level |

This lets you select an appropriate severity level for the non conformance. |

Copyright © 2026 SYSPRO PTY Ltd.