Non Conformance Cost Review

This program lets you review detailed costs associated with non conformance reports.

Exploring

This program is accessed from the Program List of the SYSPRO menu:

- Program List > Quality Management > Non Conformance Reporting > Transaction Processing

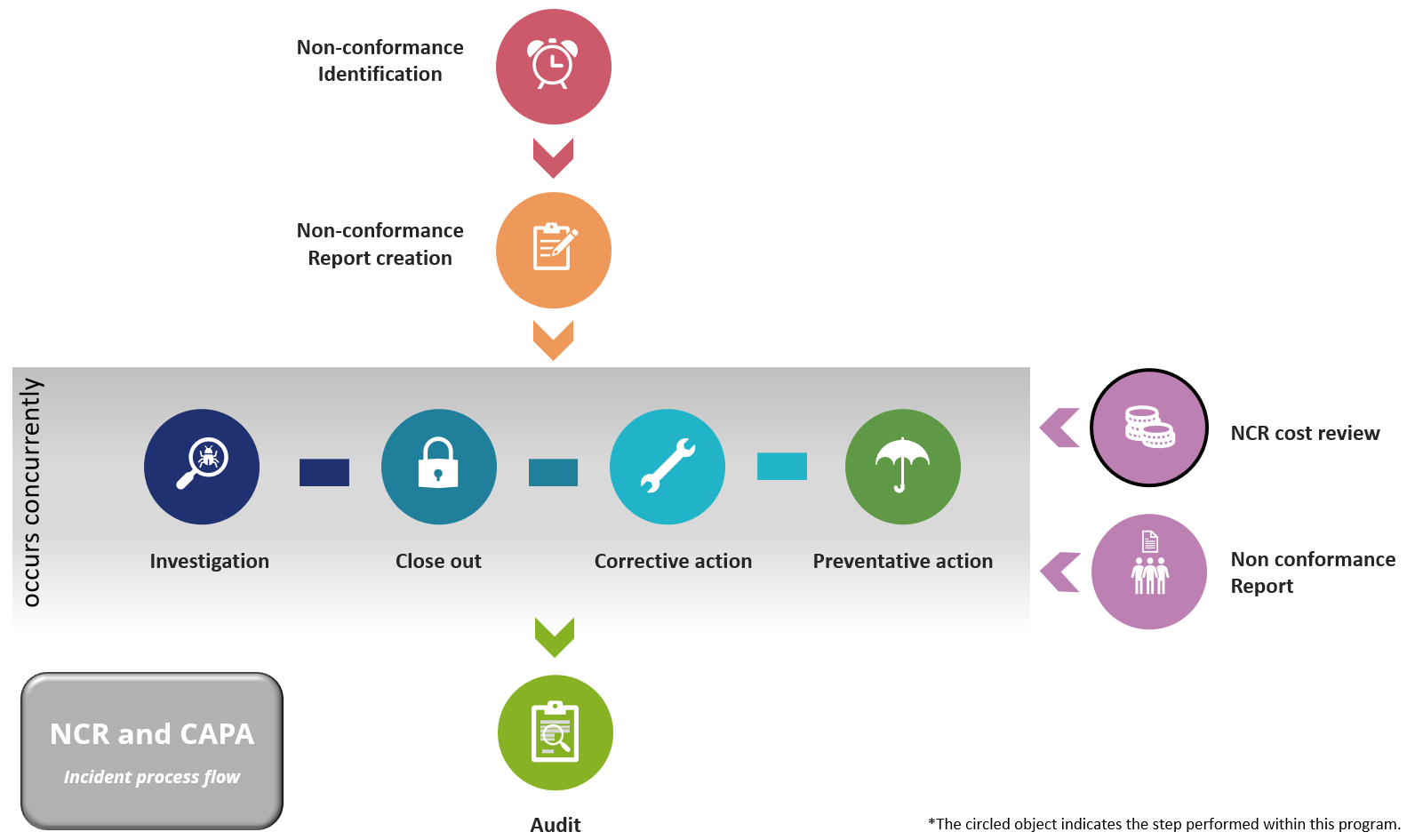

Non-conformance management refers to the process of identifying, documenting, and addressing deviations from established standards, specifications, or regulations within an organization.

It involves detecting instances where products, services, or processes fail to meet quality or compliance requirements, followed by corrective actions to prevent recurrence. Effective non-conformance management helps improve quality control, reduce risks, and ensure continuous improvement in operations.

The non-conformance process is a systematic procedure used by organizations to identify, document, analyze, and resolve deviations from established standards, specifications, or regulations.

This process typically involves several steps, including the initial detection of a non-conformance, the creation of a non-conformance report, root cause analysis, implementation of corrective and preventive actions, and verification of effectiveness. The goal of the non-conformance process is to ensure that issues are addressed promptly, preventing recurrence and promoting continuous improvement in quality and compliance.

The responsible department in non-conformance reporting refers to the specific team or organizational unit that owns, or is accountable for addressing and resolving the identified non-conformance. This department is tasked with investigating the issue, implementing corrective or preventive actions, and ensuring that the problem does not recur. The responsible department is typically selected based on the ownership of the standard raised against the NCR, ensuring that relevant expertise and resources are applied to resolve the issue effectively.

Starting

-

The Quality Management module must be installed.

You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

The following configuration options in SYSPRO may affect processing within this program or feature, including whether certain fields and options are accessible.

To use this feature, the following setup option(s) must be enabled/defined:

Setup Options > Keys > Manufacturing

-

-

Suppress leading zeros

-

Presentation length

Solving

Why don't you drop us a line with some useful information we can add here?

Using

-

Columns in a listview are sometimes hidden by default. You can reinstate them using the Field Chooser option from the context-sensitive menu (displayed by right-clicking a header column header in the listview). Select and drag the required column to a position in the listview header.

-

Fields on a pane are sometimes removed by default. You can reinstate them using the Field Selector option from the context-sensitive menu (displayed by right-clicking any field in the pane). Select and drag the required fields onto the pane.

The captions for fields are also sometimes hidden. You can select the Show Captions option from the context-sensitive menu to see a list of them. Click on the relevant caption to reinstate it to the form.

If the Show Captions option is grayed out, it means no captions are hidden for that form.

-

Press Ctrl+F1 within a listview or form to view a complete list of functions available.

-

Identify a non-conformance incident either by observation, some information on a report or dashboard that highlights an anomaly or via an automatic trigger that is supported by VBScripting.

-

Create the non-conformance report using the Non Conformance Report Maintenance program.

-

The following processes run concurrently once the NCR is created, and can be started or completed separately. All the steps in this section are maintained using the Non Conformance Report Maintenance program.

-

Record the details of the investigation in the Investigate Root-cause tab of the program.

-

Once all details have been captured, the NCR can be closed using the Closeout tab of the program.

-

Once the root cause of the NCR is known, you can define the corrective actions that must be implemented. This can be captured on the Corrective Actions tab of the program.

-

Specify the preventative actions that must be carried out within the Preventative Actions tab of the program.

-

Once all plans and action are completed the NCR is audited and the Audit section of the NCR is updated.

No other actions can be recorded during the audit phase.

-

The Non Conformance Cost Review program can be used throughout the process to report on costs relating to the non-conformance incident.

-

The Non Conformance Report can be used during the process to determine:

-

the next NCR a stakeholder should address, and

-

the next stakeholder who should address the NCR.

-

-

Referencing

Start Review

Start Review

This displays data according to the selection criteria indicated. The function is enabled when you first load the program and then by selecting the Change Criteria option.

This lets you change the currently configured review criteria.

| Field | Description |

|---|---|

|

Report selection |

This lets you select the non conformance report number(s) for which you'd like to view detailed costs in the Non Conformance Cost Review listview. |

|

Standard selection |

This lets you select the non conformance standard(s) for which you'd like to view detailed costs in the Non Conformance Cost Review listview. |

|

Department selection |

This lets you select the non conformance department(s) for which you'd like to view detailed costs in the Non Conformance Cost Review listview. |

| Field | Description |

|---|---|

|

Report number |

This indicates the non conformance report number. |

|

Description |

This indicates the description of the non conformance report. |

|

Link type |

This indicates whether the non conformance report is linked to a job, purchase order or WIP inspection. |

|

Link |

This indicates the job number, purchase order number of WIP inspection number to which the non conformance report is linked. |

|

Material cost |

This indicates the material cost associated with the job, purchase order or WIP inspection linked to the non conformance report. |

|

Labor cost |

This indicates the labor material cost associated with the job, purchase order or WIP inspection linked to the non conformance report. |

|

Total cost |

This indicates the total (labor and material) cost associated with the job, purchase order or WIP inspection linked to the non conformance report. |

|

Department |

This indicates the responsible department linked to the non conformance report. |

|

Department description |

This indicates the description of the linked department. |

|

Expected labor per unit |

This indicates the expected labor cost per unit. |

|

Expected material per unit |

This indicates the expected material cost per unit. |

|

Expected total per unit |

This indicates the expected total (labor and material) cost per unit. |

|

Stakeholder |

This indicates the stakeholder linked to the non conformance report. |

|

Standard |

This indicates the standard linked to the non conformance report. |

|

Standard description |

This indicates the description of the standard. |

| Field | Description |

|---|---|

|

Report costs |

This section indicates the material cost, labor cost and total cost associated with the job, purchase order or WIP inspection linked to the non conformance report. |

|

Standard costs |

This section indicates the standard material cost, standard labor cost and total standard cost associated with the job, purchase order or WIP inspection linked to the non conformance report. |

|

Department costs |

This section indicates the costs on department level, i.e. the department material cost, labor cost and total cost associated with the job, purchase order or WIP inspection linked to the non conformance report. |

Copyright © 2026 SYSPRO PTY Ltd.