Sales Order Entry

This program lets you record and maintain various types of sales orders.

Exploring

The sales orders that can be created and maintained include: billings, counter sales, credit and debit notes, forward orders, hierarchical orders, IBTs, scheduled orders and supply chain transfers.

Things you can do in this program include:

-

Create new orders.

-

Maintain existing orders.

-

Create a copy of an existing order.

-

Cancel an existing order.

-

Transfer stock between warehouses.

-

Generate sales order documents.

A customer order that must be processed immediately.

Insufficient stock can be placed on back order.

Documents that can be printed for this order type:

- Order acknowledgment

- Invoice

A cash sale over the counter, where payment can be made immediately.

Payment types include check, cash, credit card, or account (i.e. a debit on the customer account).

Documents that can be printed for this order type:

- Cash sale invoice

A credit (or refund) against a customer's account that produces a formal document for the customer.

Items can't be placed on back order.

Documents that can be printed for this order type:

- Order acknowledgment

- Credit invoice

A debit adjustment against a customer's account that produces a formal document for the customer.

Documents that can be printed for this order type:

- Order acknowledgment

- Invoice

A customer order that requires stock allocations to be made at a future date.

Items can be placed on back order.

Documents that can be printed for this order type:

- Order acknowledgment

An order for line items that are normally associated with a job that is linked to a contract.

Items can't be placed on back order.

Documents that can be printed for this order type:

- Order acknowledgment

- Delivery note

- Invoice

An Inter Branch Transfer enables transferring stock between branches in your company and invoicing those items at their current inventory cost price.

Items can be placed on back order.

Documents that can be printed for this order type:

- Order acknowledgment

- Delivery note

- Invoice

A customer order that you can deliver in full or part-delivery.

Insufficient stock can be placed on back order.

Documents that can be printed for this order type:

- Order acknowledgment

- Delivery note

- Invoice

A customer order that must be processed at a specific date in the future.

This type of order is useful when a customer requests different delivery dates for the items, as a line ship date is attached to each merchandise line.

Documents that can be printed for this order type:

- Order acknowledgment

- Delivery note

- Invoice

This is a transfer of stock between multiple warehouses in your company and is always processed in your local currency.

Although similar to inter-branch transfers, supply chain transfers do not require the capture of customer details.

Items to be transferred can be placed on back order.

Documents that can be printed for this order type:

- Order acknowledgment

- SCT Delivery note

This program is accessed from the Program List of the SYSPRO menu:

- Program List > Sales Orders > Sales Order Processing

- Program List > Accounts Receivable > Transaction Processing

This refers to an item that can be used as a substitute for a similar, but different item.

Within SYSPRO, assigning alternate stock codes lets you offer the customer a substitute item when there is a shortage of the original item.

If a shortage of an item occurs at the time of entering detail lines in Sales Order Entry or Quick Sales Order Entry, you can query the stock availability of the alternate stock codes and offer the customer the choice of items with available stock instead.

You can query alternate stock code information using the Inventory Query program and print alternate stock code details using the Purchasing Work Sheet report.

The Back order function in SYSPRO enables you to manage customer orders for items for which you have insufficient stock to satisfy the demand.

You can configure each customer to allow the entry of back order quantities when processing sales orders for the customer. You can also select whether to allow partial shipments for the customer, or whether the full order must be shipped.

Regardless of whether you select to release back orders automatically after you print an invoice or SCT document, the back order quantity remains in back order if:

- the order is hierarchical.

- the item is stocked and either the Requested and mandatory or Requested but optional packaging option is enabled. These lines must be manually shipped to ensure that packaging details are entered.

- multiple bins is in use for the warehouse against the order line.

- the item is traceable, ECC-controlled or serialized.

- the item is the parent or a component of a kit.

- there is insufficient stock and stock is not allowed to go negative.

| Module affected | Details |

|---|---|

|

Accounts Receivable |

You can configure each customer to allow the entry of back order quantities when processing sales orders for the customer. In addition, you can select whether to allow partial shipments for the customer, or whether the full order must be shipped. |

|

Sales Orders |

When processing a sales order for a stocked line where the order quantity exceeds the available stock on hand and stock is not allowed to go negative, the system enters the available stock in the ship quantity field and places the balance in the back order quantity field. When processing a sales order for non-stocked items where the order quantity exceeds the quantity you have entered in the ship quantity field, the system places the balance in the back order quantity field. You can configure the system to automatically display the Insufficient Stock window for the order shortage. This enables you to select an alternate stock item or to process a supply chain transfer for stocked items, or to create a purchase order, requisition or job for either stocked or non-stocked items. Alternatively, you can use the back order review to create purchase orders and requisitions for bought-out items; and jobs for made-in and subcontract items. By creating a purchase order, requisition or job that is linked to a sales order line, you ensure that when goods are received into stock the sales order line is updated automatically. You can configure the system to automatically move any remaining back order quantity to the ship quantity field after printing an invoice or SCT transfer document for a partial shipment. You use the Back Order Release program to manually release order lines that were placed on back order during sales order processing. Hierarchical orders and orders which are in suspense at the time of running the program are automatically excluded. You use the Import Back Order Releases program to release/update a batch of sales order lines by processing back order release information that is imported from an ASCII file. Although quantities are typically moved from the Back order field to the Ship quantity field on a sales order, you can indicate that quantities must move from the Ship quantity field to the Back order field. Several reports are available to assist you in monitoring order backlog. In addition, you can view back order information for sales order lines in the Sales Order Query, Sales Invoice Query, Dispatch Note Query and Customer Query programs. |

|

Bill of Materials |

If you select to run the Advanced Trial Kitting (Legacy) report using the sales order selection, then only sales order lines with a back order quantity greater than zero are included. |

|

RMA |

If you enable the Fix In-house option for an RMA receipt, then the system automatically creates a back ordered non-stocked sales order for returning the item to the customer once it has been repaired. You can also select to automatically put the order quantity into back order on the sales order you create when processing a cross shipment, or when processing an exchange on an RMA receipt. |

|

Requirements Planning |

When you run the Requirements Calculation program and select to include sales orders in requirements, then the demand quantity for each merchandise line is calculated by adding the ship and back order quantities and converting it to the stocking unit of measure. |

A customer provides the mechanism for you to raise sales orders within SYSPRO.

The static information captured against a customer is used when processing sales transactions and determines, for example, the tax and discounts applicable.

Documents generated from these transactions (e.g. invoices, credit notes, debit notes) are also stored against the customer.

The customer code can be used as a filtering tool when generating reports.

Customers are maintained using the Customers program (Program List > Accounts Receivable > Setup).

This indicates the address to which a supplier must deliver goods.

More than one delivery address may be required for larger companies that typically have a number of sites, branches or depots.

Each alternate delivery address is referenced by an address code that can be selected during purchase order processing.

You create alternate delivery addresses using the PO Multiple Delivery Address Maintenance program (Program List > Purchase Orders > Setup).

An order type assists in classifying sales orders according to the type of sale (e.g. service revenue or product revenue).

You can print the order type on your sales order documents and also use it as a selection criterion for printing a number of Sales Order reports. The order type can also be used within the Sales Analysis module to provide a breakdown of the salesperson, product class and sales history reports.

Within SYSPRO, product classes group together merchandise items that you sell (i.e. stocked and non-stocked).

It is used for reporting purposes (Sales Analysis); as a method of defining your integration to General Ledger (if linked to a branch) and caters for multiple account distributions of sales revenue and cost of sales expenses.

You can measure sales performance by product class by assigning targets and budgets to a product class.

You maintain product classes using the Product Class Maintenance program.

The following product classes cater for non-merchandise sales and are automatically created by the system whenever an Accounts Receivable branch is added:

Automatically assigned when processing freight charge lines in the Sales Order Entry and AR Invoice Posting programs.

Assigned when you run the AR Finance Charge Calculation program. The program creates a finance charge invoice record which appears on the customer's statement.

Used when processing miscellaneous charge and non-stocked merchandise lines within the Sales Order Entry and AR Invoice Posting programs, unless you have assigned different product classes for these entries.

Assigned to system-generated transactions where discounts are applied that result in rounding errors.

Used when processing sales tax transactions. This is automatically created providing the tax options are defined (Setup Options > Tax > Company Tax Options) before the product class is defined.

Used when processing sales tax transactions (Canada only). This is automatically created providing the tax options are defined (Setup Options > Tax > Company Tax Options) before the product class is defined.

Assigned when applying discounts within the Product Configurator module.

Assigned when processing labor charges in the Product Configurator module.

Assigned when processing payments from counter sales deposits.

Sales orders are used to record the sale or transfer of goods and services to both internal and external customers.

It forms a temporary legal contract between your company and the customer, as well a providing an audit trail of goods sold or transferred.

Within SYSPRO, a salesperson serves as a mandatory link for customers (i.e. a customer must be assigned to a valid salesperson).

You can use salespersons as a selection criterion within various reports, as well as for subtotalling and sequencing purposes.

You can measure salesperson performance against actual sales by assigning monthly budgets to salesperson which can be compared to actual sales made.

You maintain salespersons using the Salesperson Maintenance program.

This indicates the address of a customer to which you deliver goods.

Multiple ship to addresses lets you have more than one delivery address per customer. This is useful if, for example, you need to invoice one customer but deliver the goods to multiple locations.

Each ship to address is referenced by an address code that can be selected during sales order processing.

You create multiple ship to addresses and assign them to customers using the Multiple Ship to Addresses program (Program List > Accounts Receivable > Setup).

This applies when the EC VAT system is in use (Setup Options > Tax > Company Tax Options ).

A number of Tariff codes require the declaration of a supplementary unit, for example the number of pieces, litres or cubic metres.

Generally, a supplementary unit is required when it is a more appropriate measure of particular goods than the net mass and allows a greater degree of comparison and analysis.

Supplementary units are assigned to Inventory items using the Stock Code Maintenance program.

When adding a sales order line for an item that requires supplementary units, the supplementary unit code is passed to the order line from the stock code. A factor can then be added for calculating the supplementary unit quantity. When invoicing, the supplementary unit information is saved and made available for printing on the EC Sales reports, such as the Supplementary Declaration for Dispatches report.

When receipting a purchase order, the supplementary unit information is requested, saved and made available for printing on the EC Declaration of Arrivals report.

In SYSPRO this refers to an order type that is processed using the Sales Order Entry program.

SCT orders enable you to transfer stock between your warehouses at the current inventory cost of the stock (always in your local currency).

Stock is allocated immediately and can then be physically transferred at a later date. This lets you reserve stock to be transferred to another warehouse.

Items to be transferred can be placed on backorder.

You can optionally print an order acknowledgment and delivery note for an SCT order type.

Although only stocked merchandise lines and comment lines can be captured for a SCT order, the transfer cost multiplier assigned to the stock code/warehouse lets you include transport costs at the receiving (target) warehouse.

A transfer reference number is allocated (or entered, if you indicated that goods in transit references must be generated manually) at the time of releasing the SCT to a status 8 - To Transfer.

Although similar to inter-branch transfers, SCTs don't require the capture of customer details.

Within the Requirements Planning system, SCT orders are treated as both a supply and a demand and the system takes into account any items that are part of a warehouse transfer awaiting receipt at the target warehouse.

The tariff code identifies the goods that are the subject of a dispatch or an arrival and is the basis for most of the statistical information used by government departments, the European Commission, United Nation's agencies and businesses themselves.

The tariff code is an important data field on the Supplementary Declarations reports.

Tariff codes are used in the Landed Cost Tracking system to determine the duty rate applicable to an imported item. LCT Tariff codes require the Nationality and Country status to be defined against the supplier (Suppliers ).

Tariff codes are also used when receipting purchase orders for both stocked and non-stocked items.

The tariff code is mandatory on sales orders that are for an EC Member State customer (excluding local transactions). When adding a sales order line for a stocked item, the tariff code defined against the stock item is used. When adding a line for a non-stocked item, the tariff code must be entered.

Tariff codes are assigned to inventory items using the Stock Code Maintenance program .

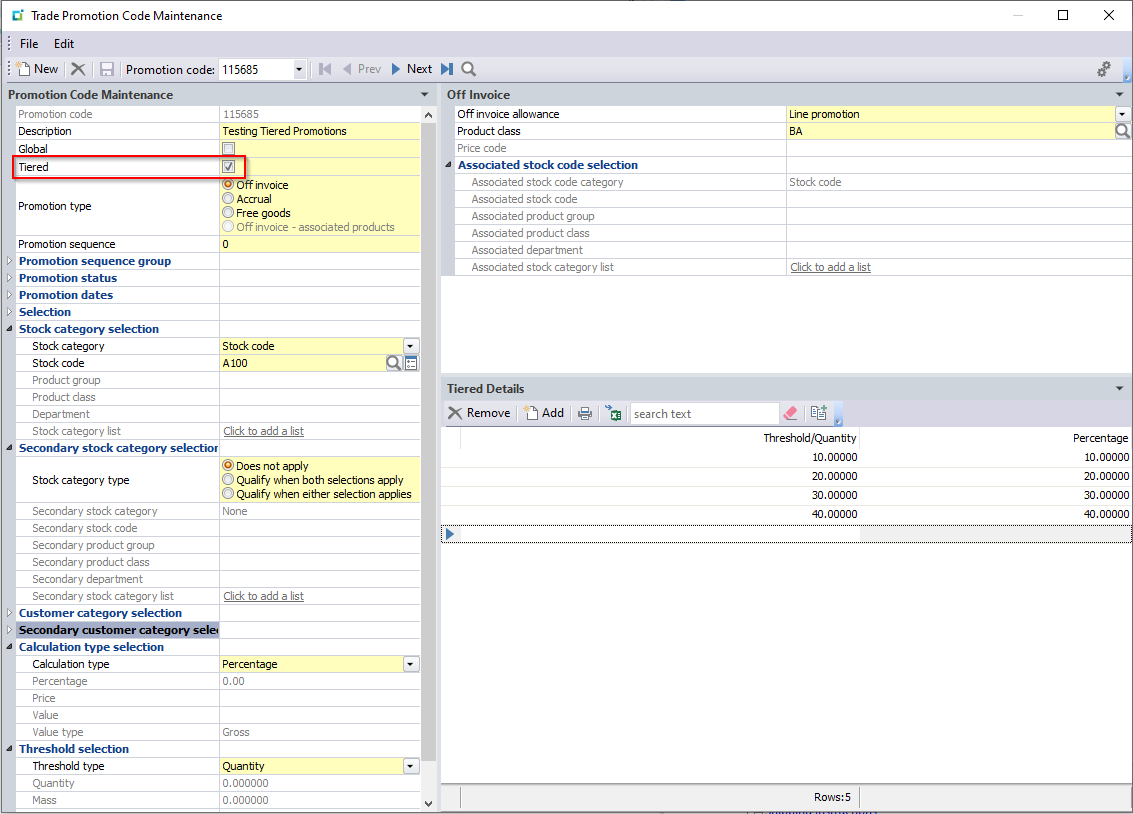

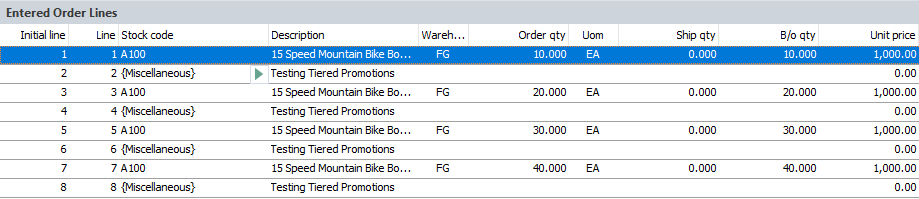

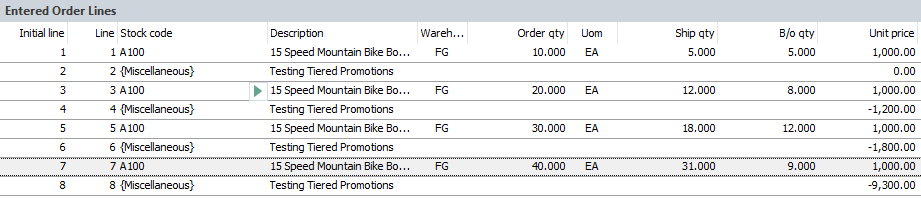

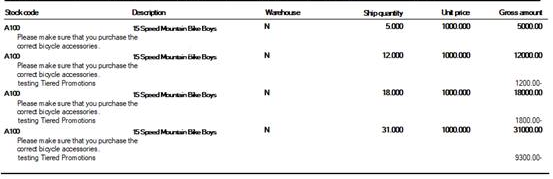

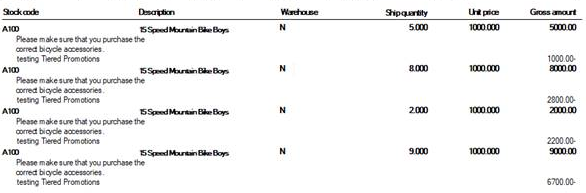

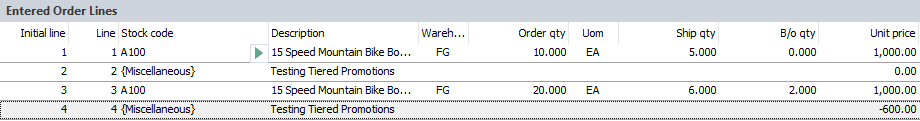

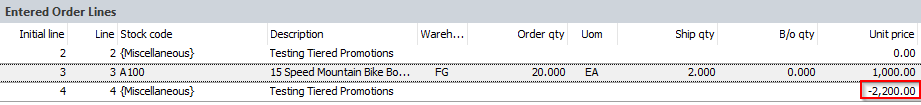

Trade promotions refers to the management and control of special deals you offer to your customers. These deals include promotions, special offers and rebates.

The Trade promotions module is integrated to the Sales order module.

This refers to a stocked item which can be transferred to another warehouse within the organization, to replenish stock in the other warehouse.

A stock item is designated as transfer-supplied using the Warehouse Maintenance for Stock Code program.

Stock items can be transferred by processing a Supply Chain Transfer (SCT) order in the Sales Order Entry program or using the various Transfer functions within the Inventory Movements program.

Within SYSPRO, a warehouse represents an actual warehouse containing your inventory items (i.e. a physical warehouse) or a grouping of your inventory according to specific characteristics of the item (i.e. a logical warehouse).

For example:

You may want to split your inventory raw materials and finished goods into different logical warehouses even though they are located in the same physical warehouse.

You maintain warehouses using the Warehouse Maintenance program.

Starting

-

Before you can print any order documents, you need to define a print format in the SO Document Formats program for the document types that you want to generate.

-

Allow Pop-Ups

Pop-ups must be allowed in your browser settings for the SYSPRO website to ensure the PayThemPayment window launches correctly from the Syspro Web UI (Avanti).

If pop-ups are blocked, the Payment window will not appear, and the system may seem unresponsive.

When processing digital payments using the Payment Gateway functionality, the following must be enabled in your browser :

You restrict operator access to activities within a program using the Operator Maintenance program.

Controls whether an operator can allocate a lot which is on hold when processing the following:

- A Supply Chain Transfer (SCT) using the Sales Order Entry program.

- A GIT Transfer Out transaction using the Inventory Movements program.

The following preferences are enabled when this activity is allowed:

-

Give warning if lot is on hold (SCT) (Sales Order Entry)

-

Give warning if lot is on hold (Inventory Movements)

Controls whether an operator can add additional lines to an existing dispatch note when reviewing dispatch notes within the Sales Order Entry program.

The operator is forced to create a new dispatch note each time items are dispatched, even if multiple dispatches are being made from one sales order.

This activity does not apply when you access the Dispatch Note Review program directly from the main menu; only when you access the Dispatch Note Review program from Sales Order Entry.

If you allow operators to add lines to existing dispatch notes, then the Manual release to invoice Manual release to invoice setup option must be enabled (Setup Options > Configuration > Distribution > Dispatch Notes).

Controls whether an operator can change the geographic area in the following programs when multiple ship to addresses are in use:

- Sales Order Entry

- SO Header Maintenance

This is set to denied by default.

Controls whether an operator can save a sales order line if a decimal overflow is encountered.

This option only applies if the following is true:

-

Multiple bins are enabled (quantities in bins are always held to 6 decimal places).

-

The maximum number of decimals defined against the stock code is less than 6.

-

Sales orders are entered in the alternate unit of measure defined against the stocked item.

If you enable this activity, then a warning message is displayed when a decimal overflow occurs, but the operator is not prevented from saving the order.

This could cause inventory and bin quantities to differ owing to rounding errors when the alternate unit of measure quantity is converted to the stocking unit of measure quantity.

Controls whether an operator can:

- insert lines into a sales order that has been partially invoiced.

- change comment lines to be more than the original number of lines.

The operator can insert any line type by selecting the Insert before line option from the Entered Order Lines listview of the Sales Order Entry program.

Controls whether an operator can create a job from a sales order when the quantity ordered is greater than the quantity available.

Controls whether an operator can change or cancel service charge lines attached to a stock item in the following programs:

- Sales Order Entry

- Quotations

This does not apply to miscellaneous service charges.

Controls whether an operator can:

-

access the Invoice whole order field on a sales order.

-

produce a delivery note or an invoice (online or in batch mode) for a partially shipped order when the Invoice whole order only option is enabled against the customer (Customers).

-

change the order status to 8 - To invoice while there are order lines containing a back order quantity.

This applies in the following programs:

- Sales Order Entry

- Quick Sales Order Entry

- SO Counter Sales

This does not apply to supply chain transfer orders.

This activity is disallowed by default.

Controls whether an operator can process a sales order for a customer when the order value after discount is less than the Minimum order value defined against the customer (Customers).

The minimum order value check is performed in the following programs:

- Sales Order Entry

- Quick Sales Order Entry

- Quotations

- Quotation Confirmation

This activity also controls whether an operator can change the value of the service charge applied to an order (by the SO Service Charges from Order Entry program) which does not meet the Minimum order value criteria.

This activity is disallowed by default.

Controls whether an operator can override the defined Reserve stock default ship status setup option (Setup Options > Preferences > Distribution > Sales Orders) when processing orders in the Sales Order Entry program.

When this activity is enabled, the operator is prompted to set the options for reserving stock when accessing the Sales Order Entry program.

In addition, the operator can indicate options for reserving stock when releasing items from backorder (Back Order Release) and when indicating demand criteria in the Inventory Demand Review program.

Controls whether an operator can override the price for a dispatched stocked line, or change the price for a dispatched non-stocked order line, using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can process a Billing using the following programs:

- Sales Order Entry

- Sales Order Entry Express

- Quotation Confirmation

Controls whether an operator can process a Counter Sale using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can cancel a line which has not yet been invoiced on a sales order that has been partially invoiced.

This activity works together with the After delivery note print maintenance setup option (Setup Options > Configuration > Distribution > Sales Orders) as follows:

-

If the setup option is set to Maintenance allowed, then the operator can cancel any line, irrespective of this activity.

-

If the setup option is set to No maintenance allowed, then the operator can cancel comment lines and non-invoiced merchandise, freight and miscellaneous lines, if this activity is set to allowed.

The operator cannot cancel partially invoiced lines.

Controls whether an operator can change the Customer or Warehouse fields when copying a sales order using the following programs:

- Sales Order Entry

- Sales Order Entry Express

This therefore controls whether the operator can copy a sales order to a new customer and from a new warehouse.

Controls whether an operator can access the following functions to create a sales order with no order lines (i.e. to create a sales order header only):

- The Create Order function from the Sales Order Entry program.

- The Assign Order Number function from the Sales Order Entry Express program.

Controls whether an operator can create a purchase order, requisition, or job from a sales order which is in a status of S - In suspense, when the quantity ordered is greater than the quantity available.

Controls whether an operator can process a Credit Note using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can process a Debit Note using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can process a Forward Order using the following programs:

- Sales Order Entry

- Sales Order Entry Express

- Quotation Confirmation

Controls whether an operator can process/create a Hierarchical Order using the following programs:

- Sales Order Entry

- Sales Order Entry Express

- Quotation Confirmation

Controls whether an operator can process an Inter Branch Transfer using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can exclude or include an entire sales order (or a sales order line for a stocked or non-stocked item) from the Material Requirements Planning calculation.

This applies when adding or maintaining sales orders using the following programs:

- Sales Order Entry

- Sales Order Entry Express

This activity also controls whether an operator can an SCT using the SO Supply Chain Transfer Creation program.

Controls whether an operator can maintain order lines or cancel an order once the delivery note has been printed, or when it is ready to be invoiced.

It also controls whether an operator can maintain detail lines for credit notes, debit notes and billings (i.e. the operator won't be able to add, change or cancel lines or add comments to these order types).

This also includes:

-

Using the WIP Inspection or Job Receipts program to accept an item into stock for a job linked to a sales order for which a delivery note has already been printed.

-

Using the Part Billings program to part bill a job linked to a sales order for which a delivery note has already been printed

This does not prevent the operator from maintaining the sales order header information.

This activity is only applicable if the After delivery note print maintenance setup option is defined as Maintenance allowed (Setup Options > Configuration > Distribution > Sales Orders).

Controls whether an operator can use the Sales Order Entry program to set a sales order as 9 - Complete, or a sales order line as C - Complete.

Controls whether an operator can use the Sales Order Entry program to add a sales order line to a delivery load, if this would cause the capacity (volume/mass) of the load to be exceeded.

Controls whether an operator can use the following programs to apply a newly-created trade promotion to an existing sales order:

- Sales Order Entry

- Sales Order Entry Express

- Dispatch Note Maintenance

Controls whether an operator can create an order using the following programs:

- Sales Order Entry

- Sales Order Entry Express

- Quotation Confirmation

Controls whether an operator can preview a counter sales invoice document on-line from the following programs, before it is printed:

- Sales Order Entry

- SO Counter Sales

In addition, the operator cannot change the printer when processing a counter sales payment from the SO Counter Sales program.

Controls whether an operator can preview a sales order document on-line (or in batch mode) before it is printed.

You typically deny access to this activity for operators printing invoices in batch mode where no operator intervention is required before each invoice is printed.

The invoices are then printed without first displaying the Print Preview screen.

Controls whether an operator can print order acknowledgment documents using the following programs:

- Sales Order Entry

- Document Print

Controls whether an operator can print a credit note using the following programs:

- Sales Order Entry

- Document Print

Controls whether an operator can print a debit note using the following programs:

- Sales Order Entry

- Document Print

Controls whether an operator can print delivery note documents using the following programs:

- Sales Order Entry

- Document Print

Controls whether an operator can print invoice, debit note or credit note documents using the following programs:

- Sales Order Entry

- Document Print

This does not prevent the operator from previewing these documents.

Controls whether an operator can print supply chain transfer documents using the Document Print program.

Controls whether an operator can process a Scheduled Order using the following programs:

- Sales Order Entry

- Sales Order Entry Express

It also controls whether an operator can create a Scheduled order from the Quotation Confirmation program.

Controls whether an operator can view the following when creating, maintaining or querying sales orders:

- Price and value of a sales order line

- Order value

- Merchandise value

- Invoice total

In addition, the transfer cost is not displayed when creating supply chain transfers or when browsing on sales order lines.

If the operator is allowed to print supply chain documents on-line (S/O Print SCT transfer) then the value of the order is printed and costs are revealed.

Controls whether an operator can process a Supply Chain Transfer using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can process a payment (including a deposit) against a sales order.

You can restrict operator access to the fields within a program (configured using the Operator Maintenance program).

Controls whether an operator can process a sales order for a customer when the order value after discount is less than the Minimum order value defined against the customer (Customers).

The minimum order value check is performed in the following programs:

- Sales Order Entry

- Quick Sales Order Entry

- Quotations

- Quotation Confirmation

This activity also controls whether an operator can change the value of the service charge applied to an order (by the SO Service Charges from Order Entry program) which does not meet the Minimum order value criteria.

This activity is disallowed by default.

Controls whether an operator can access the Customer tax regn or Customer tax reg no fields on a Sales Order Header in the following programs:

- Sales Order Entry

- Sales Order Entry Express

- SO Header Maintenance

Controls whether an operator can manually change the back order quantity for a non-stocked line during processing in the Sales Order Entry program.

Controls whether an operator can print a sales order document using Standard or SRS document printing from the print preview screen.

For Standard printing you must also enable the Print from previewed document option from the Preferences - Print Options screen of the SO Document Formats program.

Controls whether an operator can access the Salesperson field within the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can access the Tax status field on a Sales Order Header using any of the following programs:

- Sales Order Entry

- Sales Order Entry Express

- SO Header Maintenance

You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the Electronic Signature Configuration Setup program).

Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

Controls access to the creation of credit notes in the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls access to the creation of orders in the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls access to the Enter Stocked Line and Enter Non-stocked Line functions in the following programs:

-

Sales Order Entry

-

Requisition Review

-

Requisition Issue & Transfer Build Util

This is not available in Sales Order Entry Express.

Controls access to the addition of non-merchandise lines in the following programs:

-

Sales Order Entry

-

Requisition Review

-

Requisition Issue & Transfer Build Util

This is not available in Sales Order Entry Express.

Controls access to the New Order and Order Entry functions for Supply Chain Transfers in the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can process a Billing using the following programs:

- Sales Order Entry

- Sales Order Entry Express

- Quotation Confirmation

Controls access to the Cash Drawer function in the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls access to the cancellation of sales orders in the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls access to the cancellation of sales orders in the following programs:

- Sales Order Entry

- Sales Order Entry Express

This eSignature, together with the %LoadsExist condition, can be used to prevent operators from canceling sales order lines against which load planning delivery loads exist.

Controls access to the maintenance of sales orders in the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls access to the maintenance of merchandise lines in the following programs:

- Sales Order Entry

- Inventory Demand Review

- Sales Order Entry Express

Controls access to the maintenance of non-merchandise lines in the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls access to the Order Status field and function in the following programs:

- Sales Order Entry

- Sales Order Entry Express

- SO Release from Suspense

This applies to manually changing a sales order status using the Sales Order Entry program.

It does not apply when the system changes the status such as placing a sales order into suspense following a credit limit check.

Controls access to the Copy function in the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can process a Counter Sale using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can process a Credit Note using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can process a Debit Note using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can process a Forward Order using the following programs:

- Sales Order Entry

- Sales Order Entry Express

- Quotation Confirmation

Controls whether an operator can process/create a Hierarchical Order using the following programs:

- Sales Order Entry

- Sales Order Entry Express

- Quotation Confirmation

Controls whether an operator can process an Inter Branch Transfer using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls access to the Insert Before Line and Add to End functions in the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can create an order using the following programs:

- Sales Order Entry

- Sales Order Entry Express

- Quotation Confirmation

Controls access to printing sales order documents online using the following programs:

- Sales Order Entry

- Sales Order Entry Express

Controls whether an operator can process a Scheduled Order using the following programs:

- Sales Order Entry

- Sales Order Entry Express

It also controls whether an operator can create a Scheduled order from the Quotation Confirmation program.

You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

You can restrict operator access to functions within a program using passwords (configured using the Password Definition program).

When defined, the password must be entered before you can access the function.

This password restricts access to increasing the value of a credit note beyond the current value of the original invoice using the Sales Order Entry program.

For example:

The original invoice value was 1000.

The customer paid 700 off this invoice, leaving a balance of 300.

If you try to raise a credit note (linked to this invoice) for more than 300, then this password is requested.

This does not apply to credit notes created from the Return Merchandise Advice system (RMA Issues and Receipts).

A password for RMA credit notes can be defined against the password option: SO RMA Allow credit in excess of original invoice.

This password restricts access to cancelling a sales order by selecting the Cancel Order function the Sales Order Entry program.

This password restricts access to changing the Customer request date field when adding or maintaining a sales order in the Sales Order Entry program.

This password restricts access to changing sales order prices when:

- adding or maintaining a sales order using the Sales Order Entry program.

- adding or maintaining stocked quotation lines in the Quotations program.

This password restricts access to changing sales order discounts when adding or maintaining a sales order using the following programs:

- Sales Order Entry

- Quick Sales Order Entry

This does not apply to non-stocked items.

This password restricts access to overriding the Minimum price percentage above cost (defined in the Setup Options program) when:

- adding a line on a sales order.

- adding a line with a zero unit cost on a sales order or on a quotation line.

This password restricts access to releasing an order from a status of

- Sales Order Entry

- SO Release from Suspense

- Dispatch Note Maintenance

This password restricts access to processing a credit note in the Sales Order Entry program.

The password is only requested for the first credit note processed during the run of the program (i.e. it is not requested for each credit note processed).

This password restricts access to adding or maintaining a non-stocked item in the Sales Order Entry program.

This password restricts access to maintaining sales orders using the Sales Order Entry and Sales Order Entry Express program.

This password restricts access to resetting sales orders which are in a status of 0 - Order in process using the Sales Order Entry program.

This password restricts access to applying an expired contract price (if it is the lowest price) to a contract customer.

It only applies when the Prompt for expired contracts setup option is enabled (Setup Options > Preferences > Distribution > Sales Orders).

When this setup option is enabled, and the lowest price selected/suggested is from a contract that has expired, the SO Price Lookup program prompts the operator to use the price from the expired contract.

The password is requested when the operator selects to accept the contract price.

The following configuration options in SYSPRO may affect processing within this program or feature, including whether certain fields and options are accessible.

The Setup Options program lets you configure how SYSPRO behaves across all modules. These settings can affect processing within this program.

Setup Options > Configuration > Distribution > Inventory

- Multiple bins

- Stock on hand allowed to go negative

- Product configurator web setup

- FIFO valuation

- Actual costing

- Supplier/stock code interchange system

- Costing method

- Full goods in transit transfers facility

- Use zero cost bucket for returns

Setup Options > Configuration > Distribution > Sales Orders

- Packaging option

- Reserving stock required

- Load planning required

- Alternate key mandatory

- Apply check when quantity moved to ship

- Include tax in customer order value

- Basis for contract pricing

- Days to allocate scheduled orders

- Order analysis files to be generated

- After delivery note print maintenance

- Load planning required

- Negative quantities for sales orders

- Include tax in customer invoiced value

- Days to allocate scheduled orders

- Sales Order Entry/Dispatches loads

- Basis of load calculation

- Quantity discount price update

- Request lots/bins/serials

- Minimum price percentage above cost

- Pricing method

- Price group level

- Branch to be warehouse

- Change to counter sale order

- Deposits only for back order quantities

- Customer stock codes for sub-accounts

- Request commission code for coded prices

- Default customer

- Counter sales

Setup Options > Configuration > Distribution > Trade Promotions

- Credit accruals from invoices

- Credit off invoice lines from invoices

- Ship full quantity global free goods

- Ship full quantity line free goods

- Apply Trade Promotion customers discount

- Exclude free goods lines

- Text for free goods

Setup Options > Configuration > Manufacturing > Work in Progress

- Reserve stock for confirmed jobs

- Link Sales Orders directly to APS

Setup Options > Preferences > Distribution > Inventory

- Round quantities

- Unit of measure

- Use absolute days

- Automatic deplete in

- Use sales order description

Setup Options > Preferences > Distribution > Sales Orders

- Cost and gross profit in order totals

- Supply request in Sales Order Entry

- Validate order type

- Shipping via usage

- Change to descriptions for stocked items

- Request uom for order quantity

- Back orders

- Cancel open order previously invoiced

- Clear multiple ship address code

- Branch/geographic area change

- Back order release or retain

- Exclude lines that fail credit check

- Request when order release from status 4

- Cancel open order previously invoiced

- Ask reason code for new credit note

- Prompt for dangerous goods data sheets

- Notification frequency (in days)

- Auto insert dangerous goods text

- Auto insert sales order additional text

- Credit checking

- Apply check to current order only

- Credit check for order to be released

- Order date to invoice date for billings

- Fix ship address at time of order entry

- Ignore warning if item has zero cost

- Cost and gross profit in order totals

- Capture serial numbers for orders

- Prompt for expired contracts

- Include returnable item in SCT

- Reset credit status after invoicing

- Include returnable item in SCT

- Default commission code

- Theoretical uom conversion

- Default uom for order quantity

- Reserve stock default ship status

- Counter sales

- Default invoice format

- Unit discount calculated on

- Order type default

Setup Options > Preferences > Distribution > Trade Promotions

- Miscellaneous cost zero

- Maintain miscellaneous line

- Allow global promotion selection

- Automatically select global promotions

Setup Options > Preferences > Manufacturing > Work in Progress

- Job complete retain link to sales order

Setup Options > Tax > Company Tax Options

- Tax system

- Default sales tax codes

- Credit notes

- Non-stocked items

- Canadian GST required

- EC VAT system required

Setup Options > Tax > Intrastat

- Capture non EC members delivery terms

- Default nature of transaction codes

- Default delivery terms

Setup Options > Tax > Sales Orders

- Use tax code for credit notes

- Tax registration number mandatory

Setup Options > User Defined Fields > Distribution > Sales Orders

- User-defined field per order line

Setup Options > User Defined Fields > Manufacturing > Bill of Materials

- Revision

- Release

Setup Options > Keys > Financials

- Numbering method

- AR invoices/settlement

- Same invoice for different customers

- Sales order moved to invoice

Setup Options > Keys > Distribution - Sales Management

- Numbering method

- Delivery notes

- Sales orders

- Auto invoice numbering - order release

- Use source branch for SCT numbering

Setup Options > Keys > Distribution - Inventory

- Key type

- Stock codes

Setup Options > Company > General

- Nationality code

Setup Options > System Setup > General

- Multi-language for document printing

Setup Options > General Ledger Integration > General Ledger Codes

-

Dimension analysis

This must be defined per sub-module.

-

If the Sales Orders module isn't installed, then you can only process a Billing, Credit Note or Debit Note by accessing the Sales Order Entry program from the Accounts Receivable module.

In addition, various options may not be available (e.g. the Functions menu and End Order function) and any information entered is not saved, therefore you can only enter information and generate an invoice.

-

Sales orders can only be captured in the currency defined against the customer.

-

No orders of any type can be captured for a customer who is on hold.

-

Reserving stock is currently not supported for RMA (Return Merchandise Advices).

-

No new back orders are allowed for any stock item which is on Partial or Full hold.

However, if a back order quantity existed before the stock item was placed on hold, then you can ship the entire quantity if you have stock available.

-

If you process a cost modification (e.g. purchase order receipt) for a stock item that forms part of an existing Supply Chain Transfer in back order, the Unit Price field displays the old cost when placing the item into ship.

However, the transfer out is processed correctly using the newly calculated average cost when you complete the Supply Chain Transfer transaction.

-

The price group defined within the sales order header can't be changed once sales order lines have been captured.

-

Lines cannot be added to existing orders if the pricing method is changed from Manual to Price groups because the price group against existing orders will be incorrectly validated.

To add any required lines to existing orders if the pricing method is set to Price group, you must switch back to Manual. You can then set the pricing method back to Price groups. This switch will not affect the data or changes as data is not purged when changing pricing methods.

-

Trade Promotions are based on stocking unit of measure quantities. Therefore, you can't create a Trade Promotion for an alternate or theoretical unit of measure.

This means that (if you are using free goods promotions with a theoretical unit of measure) the quantity to ship for the free goods item can't be updated based on the actual quantity you are shipping for the main item, as the theoretical quantity only applies to what has been shipped.

For example:

If you want a promotion for a box of soda (alternate unit of measure) and there are 12 sodas (stocking unit of measure) in a box, then the Trade Promotion must be defined for a quantity of 12.

-

Delivery Terms and Shipping Locations can only be captured if:

- A valid entry is defined against the Nationality code setup option and the EC VAT system required setup option is enabled.

-

or, the Capture non EC members delivery terms setup option is enabled.

- If default entries for these fields are defined in the Suppliers and Customers programs, they take precedence over those defined in the Setup Options program.

- To reflect Delivery Terms and Shipping Location on order documents, ensure that these fields are enabled in the document format setup programs (only available with Word and SRS document printing).

Solving

This message is displayed when you have attempted to create a new sales order or maintain existing sales order lines against a customer who has been placed on hold.

When a customer is on hold, you can edit existing sales order headers, but you can't do the following:

-

Maintain existing sales order lines

-

Create new sales orders

This message is displayed when the following occurs:

- You define the Source warehouse and Target warehouse on the Supply Chain Transfer Warehouses screen.

- You process a Supply Chain Transfer order.

It indicates that a valid AR branch is not defined for the SCT.

Ensure that a valid AR branch is defined in the Goods in Transit Branch field of either the source and/or destination warehouse, in the Warehouse Maintenance program.

This message is displayed when maintaining an order if you select the End Order function after selecting the Change Line option from the listview titled Entered Order Lines.

Select the Save function in the Order Line pane before you select the End Order function, irrespective of whether you made any changes to the line.

This message is displayed when you enter the stock code and a Flat price contract exists for the customer in the SO Contract Prices, but the unit of measure defined against the contract in the SO Contract Pricing Maintenance program does not match the unit price for the stock code being sold.

For example:

If the unit of measure defined in the SO Contract Pricing Maintenance program is EA, then the unit of measure for the stock code on the sales order line must also be EA.

Ensure that the unit of measure defined in the SO Contract Pricing Maintenance program matches that of the stock code on the sales order line.

Full error message:

This error can occur due to rounding when converting between the different units of measure for a stock code.

For example:

Based on how you defined the conversion factors, you could have a conversion calculation such as:

1/12 = 0.0833333333333

This would then trigger this error message.

To prevent this error, enable the Round quantities setup option for the Unit of measure (Setup Options > Preferences > Distribution > Inventory).

Full error message:

This is displayed when you enter a unit of measure which is not defined in the Selling Price Unit of Measure program.

If you select OK, then you can enter the conversion factor for the unit of measure you entered, but the conversion factor is used for the current line only and is not saved.

If you select Cancel, then you have to enter a unit of measure which exists in the Selling Price Unit of Measure program.

This is displayed when a Scheduled order line is linked to a Purchase order, Job or Requisition and you change the Ship date.

This means that the current scheduled (due) date on the line is currently within the scheduled period, and is thus allocated.

You are attempting to change the date to one that is outside the allocation period.

Select a date that falls within the allocation period.

Full error message:

This applies to Load Planning and is displayed when you try to add an order line that would cause the load capacity (mass/volume) to be exceeded.

You can only add the line when the activity: SO Order Entry - add line to delivery load where capacity is exceeded is enabled for your operator code.

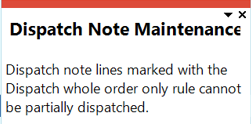

This message may be displayed in the Dispatch Note Review program when you have attempted to dispatch selected sales order lines or you have attempted to change the dispatch quantity within the Dispatch Note Maintenance program, while one of the following options are enabled:

-

The Dispatch whole order option against the sales order (Sales Order Entry).

-

The Dispatch whole order only option against the customer (Customers).

You can't dispatch partial orders (i.e. dispatch selected sales order lines) or change the dispatch quantity when the Dispatch whole order only option is enabled against the customer or the Dispatch whole order option is enabled against the sales order.

You can either disable one of the above options or you have to wait to dispatch the whole order.

Full error message:

This warning message is displayed in the Sales Order Entry program when you maintain a sales order linked to a Work in Progress job.

Jobs are linked to sales order lines by stock code, warehouse, quantity and date required. Therefore, changing any of these critical fields on the sales order, or changing the order status by placing it in suspense, can affect this 'link'.

Changes do not necessarily invalidate the link, but they may also need to be manually applied to the job.

For example:

Changing the date on the sales order will not update the job.

Similarly, changing the quantity on the sales order does not update the job automatically.

This warning message is displayed in the Sales Order Entry program when all of the following conditions are true:

- The EC VAT system required setup option is disabled (Setup Options > Tax > Company Tax Options).

- The Capture non EC members delivery terms setup option is enabled (Setup Options > Tax > Intrastat).

- A valid EC Nationality code is defined against the customer or the order.

Although you can ignore the warning and capture the order, you cannot end the order until you change the Nationality code to a non EC nationality.

You cannot maintain an order which is in a status of 0 - Order in process, until the system resets the status for you.

This message is typically displayed in the Sales Order Entry program when you attempt to maintain an order which is in a status of 0 - Order in process.

The system cannot know exactly why the order is in a status of 0 - Order in process, so you need to ensure that the order is not actually currently being maintained by another operator before proceeding.

If it is not currently being maintained by another operator, then select Yes to continue.

You cannot maintain an order which is in a status of 0 - Order in process, until the system resets the status for you.

This message is displayed when you select Yes to continue maintenance of an order that is currently in a status of 0 - Order in process.

The system is requesting your permission to check that all lot, bin and serial allocations have been successfully completed for all lines on the sales order, before it resets the order status for you.

Select Yes to perform the validation and reset the order status if all allocations are found to be complete for the order.

If the allocations are not found to be complete, then one of the following occurs:

-

For a sales order you are prompted to reset the order status anyway.

If you accept, then the sales order status is reset, leaving the allocations as they were. The responsibility lies with you to correct the allocations.

If you do not accept, then the sales order is left in a status of 0 - Order in process.

- For a credit note attached to an invoice, the system will restore previous allocations as per the invoice.

- For a credit note not attached to an invoice, you are prompted to re-enter allocations.

If all lot, bin and serial allocations were found to have been done for the order, the following message is displayed:

The system has reset the order from status 0 - Order in process to its previous status, so you can now maintain it.

If you select No, then the following message is displayed:

The system will not allow you to maintain the order as the lot, bin and serial allocations have not been checked and the order status is still 0 - Order in process.

If you attempt to maintain the order again, the message: is displayed.

The following message is displayed in the Sales Order Entry program when you process a Credit note and link it to an invoice:

You are prompted to select the original lines from the invoice (see SO Header Maintenance and Document Print).

If you select Yes to copy the original invoice lines to the credit note, then the following applies to costing:

- If FIFO costing is in use, then the credit note cost is taken from the invoice.

- If the invoice cost was entered against the original sales order lines, then there is a 'c' in the PrtOnInv field and the FIFO cost on the reprint record is used for the credit.

- If you are using FIFO costing (but not Actual Costing) then a new FIFO bucket is created using the cost from the Invoice reprint file (providing the cost was entered against the original sales order lines).

- If you are not using FIFO costing, then the current warehouse cost of the item is used for the credit note and not the original cost on the original invoice.

The following message is displayed inside Sales Order Entry when you maintain the ship quantity for a Free goods promotion line which is currently in back order:

The suggested free goods quantity to ship (nn) is the number of units of the free goods that has been earned according to the quantity shipped of the line item(s) that generated the free good line.

The suggested free goods quantity may be less than the total number of units of the free goods, because the calculation is based on the shipped quantity, not the ordered quantity.

If you select Yes from the message pane, then the suggested quantity displayed is put into ship.

If you select No, then the suggested quantity of the free good remains on backorder.

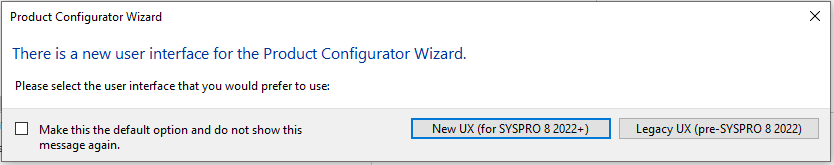

This message is displayed when you select the Configure link or button to customize a product from within one of the following programs:

-

Sales Order Entry

-

Quotations

-

Estimates

-

Structures and Routings

-

Job Entry

Depending on your requirements, proceed as follows:

-

Select New UX to use the Product Configurator Wizard program to create a customized product.

- Select Legacy UX to use Configurator Wizard program to create a customized product.

The Configurator Wizard program will be discontinued in the following release.

When a customer is on hold, you can edit existing sales order headers, but you can't do the following:

-

Maintain existing sales order lines

-

Create new sales orders

The SO Reserve or Ship Stock screen is displayed when you initially access the Sales Order Entry program if the following are true:

- The Reserving stock required setup option is enabled (Setup Options > Configuration > Distribution > Sales Orders).

- You are allowed to override the reserve stock options when shipping sales orders.

You can enter a code to automatically retrieve the associated ship via message assigned to the code, if the Shipping via usage setup option is defined as Coded (Setup Options > Preferences > Distribution > Sales Orders).

Define the key type for non-stocked codes at the Stock codes setup option (Setup Options > Keys > Distribution - Inventory).

A non-stocked code must conform to the key type defined.

The Alternate key is defined on the Order Header and provides an additional sequencing key for your orders.

The Alternate key must be entered when capturing orders if the Alternate key mandatory setup option is enabled (Setup Options > Configuration > Distribution > Sales Orders).

You can configure the generation of a default entry for the Alternate key based on the following:

- The customer’s geographic area

- The warehouse assigned to the order

- The branch assigned to the order

To print the alternate key on sales order documents, a print position must be defined in the document format that you select to use for your documents (SO Document Formats).

You can tailor the wording for the Alternate key prompt to suit your own requirements by defining the Default alternate key setup option (Setup Options > Configuration > Distribution > Sales Orders).

Tax Connector - Avalara Considerations:

When using the Tax Connector - Avalara , this field is used to populate the Reference code field when submitting transactions to Avalara.

For example:

If you enter ExWorks or Collection in this Alternate Key field, then this entry is used as the Reference Code when submitting to Avalara.

You can then configure an Advanced Rule within Avalara to consider the Reference Code in the tax calculation.

The APS system is updated whenever a sales order is added, copied, changed or canceled, as long as the following are true:

- The Advanced Planning and Scheduling system is installed.

- The Link Sales Orders directly to APS setup option is enabled (Setup Options > Configuration > Manufacturing > Work in Progress).

The Area is defined on the Order Header and indicates the geographic area applicable to the customer for this order.

You can change the geographic area when the following are true:

-

The Branch/geographic area change setup option is defined as Allowed (Setup Options > Preferences > Distribution > Sales Orders).

General Ledger integration must be defined for the branch/geographic area combination when this setup option is set to Allowed - GL integration check.

- Multiple ship to addresses are in use, providing you are allowed to change the geographic area when multiple ship-to-addresses are in use.

If you change the geographic area for an order with existing lines and you are using USA tax defined by geographic area (Setup Options > Tax > Company Tax Options) then you are prompted to change all lines to the new area tax codes.

Select Yes to update all lines accordingly.

The Average days to pay information is displayed in the Customer Information pane.

It is recalculated as follows each time you use the AR Payments and Adjustments program to process a payment for the customer, or you run the Balance function of the AR Period End program:

- For each invoice or debit note paid, two totals are updated:

- Total number of invoices paid

- Total number of days to pay

- When a payment is processed:

- The Total number of invoices paid is increased by 1 for each invoice / debit note paid in full.

- The Total number of days to pay is increased by the number of days taken to pay (i.e. the number of days between the invoice date and the payment date).

-

The new average number of days to pay is calculated as:

Total number of days to pay / Total number of invoices

-

Enable the Stock code interchange required option against the customer in the Customers program.

-

Use the Customer Stock Codes program to define the link between the customer's stock code and the SYSPRO stock code.

-

Enable the Supplier/stock code interchange system option (Setup Options > Configuration > Distribution > Inventory).

-

Define a supplier code against the SYSPRO stock code (Stock Code Maintenance ).

-

Use the Supplier Stock Code Cross Reference program to create links between the supplier's catalogue numbers and SYSPRO stock codes.

When adding a stocked order line to an order, the Field Selector option in the Stock code field enables you to select which stock code linked to a SYSPRO stock code you want to enter.

Providing a link exists between the customer's stock code and the SYSPRO stock code, the customer's stock code is saved against the sales order line.

This is regardless of whether you enter the customer's stock code or the SYSPRO stock code on the sales order line.

If you enter a SYSPRO stock code and more than one customer stock code is linked to this stock code, then the first customer stock code detected is saved against the order line.

When processing orders for sub-account customers, you can use the customer account defined against the sub-account and/or the master account. However, this depends on your configuration of the Customer stock codes for sub-accounts setup option (Setup Options > Configuration > Distribution > Sales Orders).

The customer's stock code can be printed on sales order documents.

Providing a link exists between the supplier's catalog number and the SYSPRO stock code, the supplier's catalog number is saved against the order line.

This is regardless of whether you enter the supplier's catalog number or the SYSPRO stock code on the sales order line.

The supplier's catalog number can be printed on sales order documents.

To automatically ship free goods for a sales order line when the full quantity of the free item is available and the parent item is also shipped:

-

For a Tiered free goods promotion:

Enable the Ship full quantity line free goods setup option (Setup Options > Configuration > Distribution > Trade Promotions).

-

For a Global free goods promotion:

Enable the Ship full quantity global free goods setup option (Setup Options > Configuration > Distribution > Trade Promotions).

The Minimum order rules defined against the customer are applied when you end an order.

To change the order type of a normal order to be a Counter sales order when processing deposit transactions against the order, enable the Change to counter sale order setup option (Setup Options > Configuration > Distribution > Sales Orders).

The Take Payment function is only available under the following conditions:

-

The Counter Sales module is installed.

-

Your operator code is permitted access to the SO Take payment activity.

-

The order type is Order, Billing, Scheduled or Credit note.

-

The status of the order is 4 - In warehouse or 8 - To invoice.

Otherwise the Take Payment option is enabled if both of the following are true:

- There are order lines on back order and the Deposits only for back order quantities setup option is enabled (Setup Options > Configuration > Distribution > Sales Orders).

- The Change to counter sale order setup option is disabled (Setup Options > Configuration > Distribution > Sales Orders).

You can't change the bin, lot or serial allocation quantities at the Bins/Lots/Serials field when processing a credit note against an invoice.

The Edit hyperlink is not available when processing a credit note against an invoice, as you must first change the order quantity and save the credit note. The Bins, Lots & Serial Allocation program will then be launched where you can change the quantity against the allocation.

Configuration required

-

TheBack order release or retain setup option must defined as Manual or Automatic (Setup Options > Preferences > Distribution > Sales Orders) as hierarchical sales orders are always placed on back order automatically.

Hierarchical sales order creation

-

You can't enter stocked lines on hierarchical sales orders.

-

All non-stocked lines must have three decimals to enable the Part Billings program to part book decimal portions.

-

Although you can enter Miscellaneous and Freight lines, they are not assigned to the job hierarchy.

To assign these charges, you must enter them as allocations.

-

You need to create a hierarchical sales order to be able to link a hierarchical job to the sales order line.

-

The customer against a hierarchical job must match the customer on the sales order.

-

Once allocated to a sales order, a hierarchical job number cannot be used for another sales order.

-

When adding non-stocked lines against a hierarchical order, the price must be greater than zero (i.e. you cannot save a line with zero-price on a hierarchical order).

Hierarchical sales order maintenance

-

Since the order quantity for hierarchical orders is automatically placed onto back order, maintenance of the Ship quantity is not allowed.

Quantities can only be released from back order using the Part Billings program.

-

If the net value of an order line is changed when maintaining a hierarchical sales order, the value of the change must be distributed to a valid hierarchy.

The value of the change is added to either the original sales value or is entered as an adjustment value.

-

When adding new lines to a hierarchical sales order you must indicate whether the value of the line must be added to the original sales value or the adjustment value.

Hierarchical sales order release

-

You cannot use the Back Order Release program to release hierarchical sales orders.

-

Once a delivery note has been produced and the order is in a status 4 - In warehouse, you can only release the order for invoicing using the Part Billings program.

Hierarchical sales order deletion

-

You cannot cancel an hierarchical order which is ready for invoicing.

This is because the Part Billings program has been used to release the back ordered lines and the cost of sales and billings have already been updated.

There is no way of reversing the cost of sales and billing entries that have been updated.

-

Deleting an hierarchical sales order removes from the order master table and from the job hierarchy details file.

As a result all details for the sales order are removed.

Hierarchy distribution

-

When you add an order line and the sales order details have been entered and saved, the P&C Distribute Sales Order Value program is automatically displayed to enable you to distribute the sales order value across the heads and sections of the job hierarchy.

The net value of the order line can be distributed against any combination of heads and sections held against the job.

The same job number can be used again (against the same order) if, for example, you have to add a new line to the sales order because of an increase in the scope of the contract.

-

The P&C Distribute Sales Order Value program is automatically loaded when the net value of an hierarchical sales order line changes.

-

When you maintain the order line, then within the P&C Distribute Sales Order Value program, you can use the Change option to change the value already distributed to a hierarchy; the Delete option to delete a distribution entry; and the Distribution option to distribute the line value to a hierarchy.

You cannot exit the P&C Distribute Sales Order Value program until the undistributed value reaches zero.

Configuration considerations

-

SCT orders are only available if the Full goods in transit transfers facility setup option is enabled (Setup Options > Configuration > Distribution > Inventory).

-

You can only create a supply chain transfer for a non-transfer supplied warehouse when the sales order preference Allow SCT for no-xfer supplied warehouses is enabled.

-

When the Use sales order description setup option is enabled (Setup Options > Preferences > Distribution > Inventory), the stock code description entered on SCT orders is used for the stock item on the following:

- Transfer document

- GIT Trial Balance report

- GIT Detail Report report

-

The Branch defaults to the branch defined against the receiving warehouse.

However, the Branch defaults to the branch defined against the source warehouse if sales order numbering method is defined By branch and the Use source branch for SCT numbering setup option is enabled (Setup Options > Keys > Distribution - Sales Management).

-

When the Include returnable item in SCT setup option is enabled (Setup Options > Preferences > Distribution > Sales Orders), any attached service charge for a returnable item is added to the SCT order.

The returnable item is always issued from the source warehouse and receipted into the target warehouse for the SCT.

SCT processing considerations

-

The price at which stock is transferred is the current Inventory cost of the stock.

-

SCT orders created from the Supply Chain Review program are always created as back orders.

-

Although an SCT may proceed through the normal order process of printing a delivery note before releasing it to a status 8 - To invoice, it can also proceed directly from a status 1 - Open order line to status 8 - To invoice without the printing of a delivery note.

-

A transfer reference number is allocated (or entered, if you selected a manual numbering method) at the time of releasing the SCT to a status 8 - To invoice.

-

When you process an SCT for a Kit part defined as a type Kit or Sub in the Stock Code Maintenance program, the appropriate components are selected at cost.

Both the Kit parent and the component(s) must exist in the source warehouse.

-

The creation of a transfer on completing the SCT ignores the parent part.

The Transfer In process receipts each component into stock as a separate item.

SCT sales order creation

-

Only stocked merchandise lines and comment lines can be entered on SCT orders.

However, the transfer cost multiplier assigned to the stock code/warehouse provides the facility to include transport costs at the receiving warehouse.

-

You can't define a branch to use for supply chain transfers, as the branch is not relevant and is only used for product class validation.

Nothing is posted to the branch for an SCT.

-

Tax can't be applied to an SCT transaction.

If you require tax to be applied, then you need to use an IBT (inter Branch Transfer).

The following program(s) and business object(s) currently manipulate or consider the line status:

-

Release Reserved Stock

Sets the line to a status of 8 - Line ready to invoice after the stock is released.

If the Invoice whole order option is enabled at header level, you cannot change an order's status to 8 - To invoice while there are order lines containing a back order quantity, unless your operator code has activity access to override the Invoice whole order rule.

In addition, you can only change an order status from a status of S - In suspense if there are no live dispatches for the order.

If you change the status of an order in suspense, you are prompted to enter the relevant password to release the suspended order if one is defined against the SO Entry of credit authority on release of sales orders option in the Password Definition program.

The Line Notes option is only enabled after you save the order line.

Therefore, you can only attach notes to a line when maintaining the order line (i.e. right click on the line in the Entered Order Lines listview and select the Change Line option).

Intrastat details apply when the EC VAT system required setup option is enabled (Setup Options > Tax > Company Tax Options).

In order to change the stock code description, ensure that the Change to descriptions for stocked items setup option is enabled (Setup Options > Preferences > Distribution > Sales Orders).

You can change the unit of measure for a stocked line if both of the following are true:

- The stocking, alternate or other units of measure of the item are different (Stock Code Maintenance)

- The Request uom for order quantity setup option is enabled (Setup Options > Preferences > Distribution > Sales Orders).

This depends on your Action selection at the Duplicate customer purchase order number setup option (Setup Options > Preferences > Distribution > Sales Orders).

Based on this configuration, you are either warned or disallowed from continuing if you enter a customer purchase order that has already been used on another sales order.

When the Invoice whole order only option is enabled against the customer, you can only change the Invoice whole order option against an order when you have access to the SO allow override of 'Invoice Whole Order' rule activity (Operator Maintenance ).

An Order quantity error message is displayed if the resulting quantity is zero after converting from an alternate unit of measure to the stocking unit of measure for the number of decimals defined against the stock code.

For example:

A stock code is defined with the following:

- Stocking uom = EA