Cycle Count

The Cycle Count feature lets you perform partial stock counts at specific intervals without disrupting daily operations.

This feature is designed to be used with the SYSPRO Scheduler to allow for the planning and scheduling of specific cycle-counts for particular areas in the warehouse.

Exploring

The programs related to this feature are accessed from the Program List pane of the SYSPRO menu:

- Program List > Inventory > Cycle Counting System

This refers to an inventory auditing procedure whereby a small subset of inventory items (or specific locations) are designated to be counted on a specified cycle.

The information derived from the cycle count can be used to determine the accuracy of stock levels within the entire warehouse (e.g. if discrepancies are found between actual and system stock levels, similar variances may be expected in other areas of the warehouse).

A stock code is a number that uniquely identifies an inventory item that is bought or manufactured and which is typically stored in one or more warehouses.

All activity relating to the forecasting, purchasing, manufacturing, stocking and selling of a stocked item is tracked by means of the stock code.

A stock code can be linked to one or more lot numbers if the item is defined as lot traceable. If there is a warranty, the stock code can be defined as serialized and linked to one or more serial numbers.

Within SYSPRO, a warehouse can represent an actual warehouse containing your inventory items (i.e. a physical warehouse) or it can represent a grouping of your inventory according to specific characteristics of the item (i.e. a logical warehouse).

For example:

You may want to split your inventory raw materials and finished goods into different logical warehouses even though they are located in the same physical warehouse.

You can define a default warehouse to use for transactions at company level as well as at operator level (this overrides the company default).

Starting

To use this feature, the following module(s) must be installed according to the terms of your software license agreement:

- Inventory Control

To use this feature, the following setup option(s) must be enabled:

Setup Options > Configuration > Distribution > Inventory

- Fixed bins

- Multiple bins

- Associate serials by bin

-

Show Warehouses (hyperlink)

- Accounting for shortages

You can secure this feature by implementing a range of controls against the affected programs. Although not all these controls are applicable to each feature, they include the following:

- You can restrict operator access to activities within a program (configured using the Operator Maintenance program).

- You can restrict operator access to the fields within a program (configured using the Operator Maintenance program).

- You can restrict operator access to functions within a program using passwords (configured using the Password Definition program). When defined, the password must be entered before you can access the function.

- You can restrict access to the eSignature transactions within a program at operator, group, role or company level (configured using the eSignature Setup program). Electronic Signatures provide security access, transaction logging and event triggering that gives you greater control over your system changes.

- You can restrict operator access to programs by assigning them to groups and applying access control against the group (configured using the Operator Groups program).

- You can restrict operator access to programs by assigning them to roles and applying access control against the role (configured using the Role Management program).

-

Multiple bins must be enabled for all warehouses that use cycle counting.

Solving

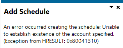

This message is displayed when you try to save a schedule without having configured the required setup options.

The program requires access to the credentials of a domain user with elevated permissions. This ensures that the Windows tasks are created with the Run with highest privileges option enabled.

Configure the following credentials in the Reporting tab of the System Setup program:

Scheduler authentication

- User name

- User password

This message is displayed when you try to save a schedule without having configured the required setup options correctly.

The program requires access to the credentials of a domain user with elevated permissions. This ensures that the Windows tasks are created with the Run with highest privileges option enabled.

Verify that the following credentials are configured correctly in the Reporting tab of the System Setup program:

Scheduler authentication

- User name

- User password

You can change the quantities for active cycle counts using the Cycle Count Capture program.

- To replace the quantity that was originally captured, enter the recounted quantity and enable the Replace captured quantity option.

- To supplement the original quantity, enter the quantity you want to add to the quantity that was originally captured.

- To increase the original quantity captured, enter the difference with a preceding plus character (+).

- To decrease the original quantity captured, enter the difference with a preceding minus character (-).

Using

The programs related to this feature are accessed from the Program List pane of the SYSPRO menu:

- Program List > Inventory > Cycle Counting System

- Create the cycle count per warehouse section and include the items that must be counted using the Cycle Count Maintenance program.

- Schedule when the cycle count should be performed using Maintain Schedules program (accessed from within the Browse on Cycle Counts program).

- Select the cycle count to activate it (using the Functions column of the Browse on Cycle Counts program).

-

Capture the actual stock quantities counted (including lots and serials) using the Cycle Count Capture program.

- Cancel an activated cycle count, print cycle count forms and view quantity variances by clicking the Select link in the Functions column of the Browse on Cycle Counts program.

- Edit the captured quantities if errors were made or recounts were done, using the Cycle Count Capture program.

- Review discrepancies between the actual and original stock quantities per stock code using the Cycle Count Review and Confirm program.

-

Once reviewed, select to either accept or recount the stock.

You are prompted to recount if the discrepancy exceeds the percentage specified at the Cycle count variance % field of the Warehouse Bins program.

- Once recounted, capture the stock quantities using the Cycle Count Capture program.

- Review any differences between the recounted and original stock quantities per stock code using the Cycle Count Review and Confirm program.

-

When you are satisfied with the numbers, accept the cycle count lines and confirm the cycle count using the Cycle Count Review and Confirm program.

When the cycle count is confirmed, inventory can be updated and transactions posted to the ledger, depending on your selection at the Accounting for shortages field in the Warehouse Maintenance program.

The Cycle Count Confirmation screen is displayed where you can view the cycle count messages.

-

Once the cycle count is closed, you can view cycle count data and quantity variances using the Cycle Count Captured Query program.

While the cycle count is active, you can view cycle count data using the Cycle Count Query program.

- Purge redundant cycle count data using the Cycle History Purge program.

The following indicates areas in the product that may be affected by implementing this feature:

This is a new program that lets you add, maintain and delete cycle counts, as well as select bins and stock items you want to include in the cycle count.

This is a new program that lets you capture the results of the cycle count per bin, lot and serial for each stock item included in the cycle count.

This is a new program that lets you confirm or recapture the counted quantities and confirm the cycle count.

This is a new program that lets you process the cycle count.

This is a new program that lets you activate, edit or cancel a cycle count, as well as schedule a cycle count using the SYSPRO Scheduler.

This is a new program that lets you delete inactive cycle counts that are no longer required.

This is a new program that lets you view the quantities there were captured for every stock item included in the cycle count.

This is a new program that lets you view historical cycle count data.

This is a new program that lets you view cycle count data of accepted and confirmed cycle counts.

The Cycle count variance % field was added for you to specify an acceptable variance percentage. This is used when the variance between counted quantities and system quantities is calculated.

This is a new business object that lets you select stock code items that will form part of the cycle count.

This is a new business object that lets you add, maintain and delete cycle counts.

This is a new business object that lets you cancel or stop cycle counts.

This is a new business object that lets you delete cycle counts and the cycle count data.

This is a new business object that lets you query cycle count data per bin and view variances between actual and counted stock quantities.

This is a new business object that lets you confirm the entered stock code quantities for cycle counts.

This is a new business object that lets you query cycle count quantities.

This is a new business object that lets you capture the stock code quantities that were counted during the cycle count.

This is a new business object that lets you view cycle count quantities, variances and how often the quantities were edited because of recounts.

This is a new business object that is executed from the scheduler and prints cycle count forms according to the schedule.

This is a new business object that lets you view a list of all cycle counts, regardless of their status.

This is a new business object that lets you query cycle count data of accepted and confirmed cycle counts.

-

The Cycle Count feature is designed to work with the Add/Maintain Schedule program which lets you manage cycle counts by printing cycle count forms according to scheduled intervals.

- When opting for a recount, the bin quantities are cleared and must be recaptured.